Non-contact angle tracking system and method based on passive RFID

A tracking system, non-contact technology, applied in the field of RFID passive sensing and industrial Internet, can solve the problems of inertial sensors such as non-maintenance overhead, high cost and delay, to improve system security and reliability, reduce overhead, and facilitate The effect of deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

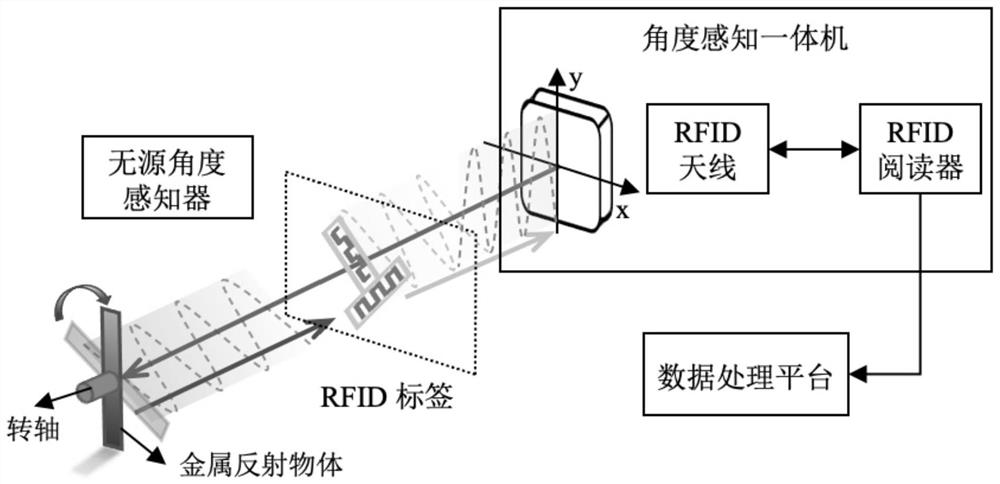

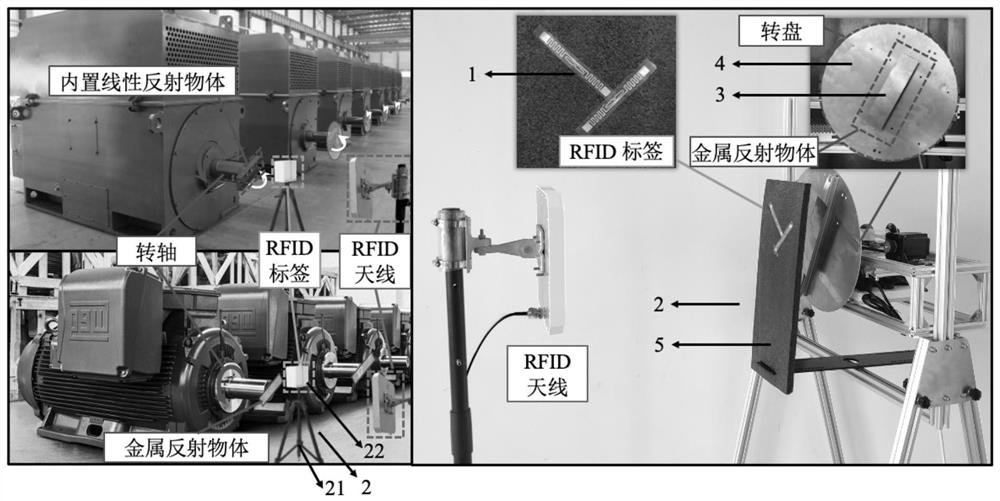

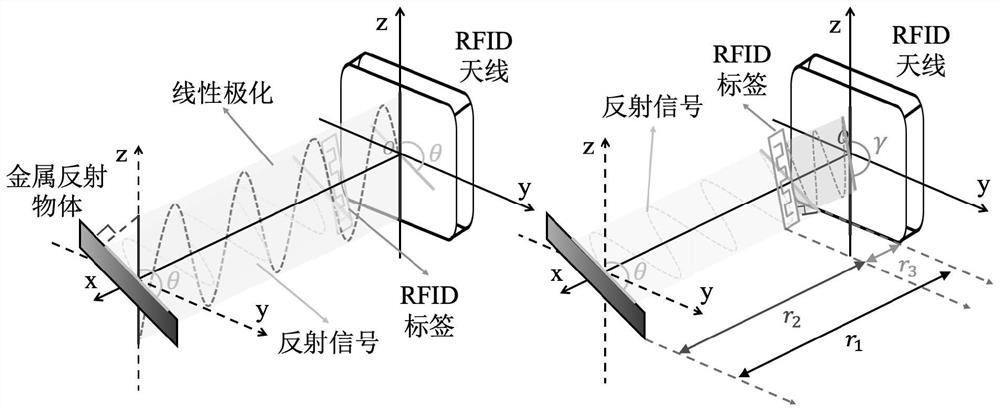

[0052] refer to figure 1 and figure 2 , a non-contact angle tracking system based on passive RFID of the present invention, comprising: a passive angle sensor, an angle sensing all-in-one machine and a data processing platform, wherein the passive angle sensor perceives the rotation of the rotating shaft in a passive manner and concurrently The angle sensing all-in-one machine receives the signal from the passive angle sensor and sends it to the data processing platform. The data processing platform calculates the rotation angle at each moment based on the received signal, thereby realizing angle tracking.

[0053] In the embodiment of the present invention, the passive angle sensor is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com