Method for monitoring a chain hoist and chain hoist

A pulley block and chain technology, applied in the direction of engine control, clockwork mechanism, portable lifting device, etc., can solve the problems of not being able to identify the deviation of the motor speed, and achieve the effects of avoiding thermal overload, reducing wear, and avoiding falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

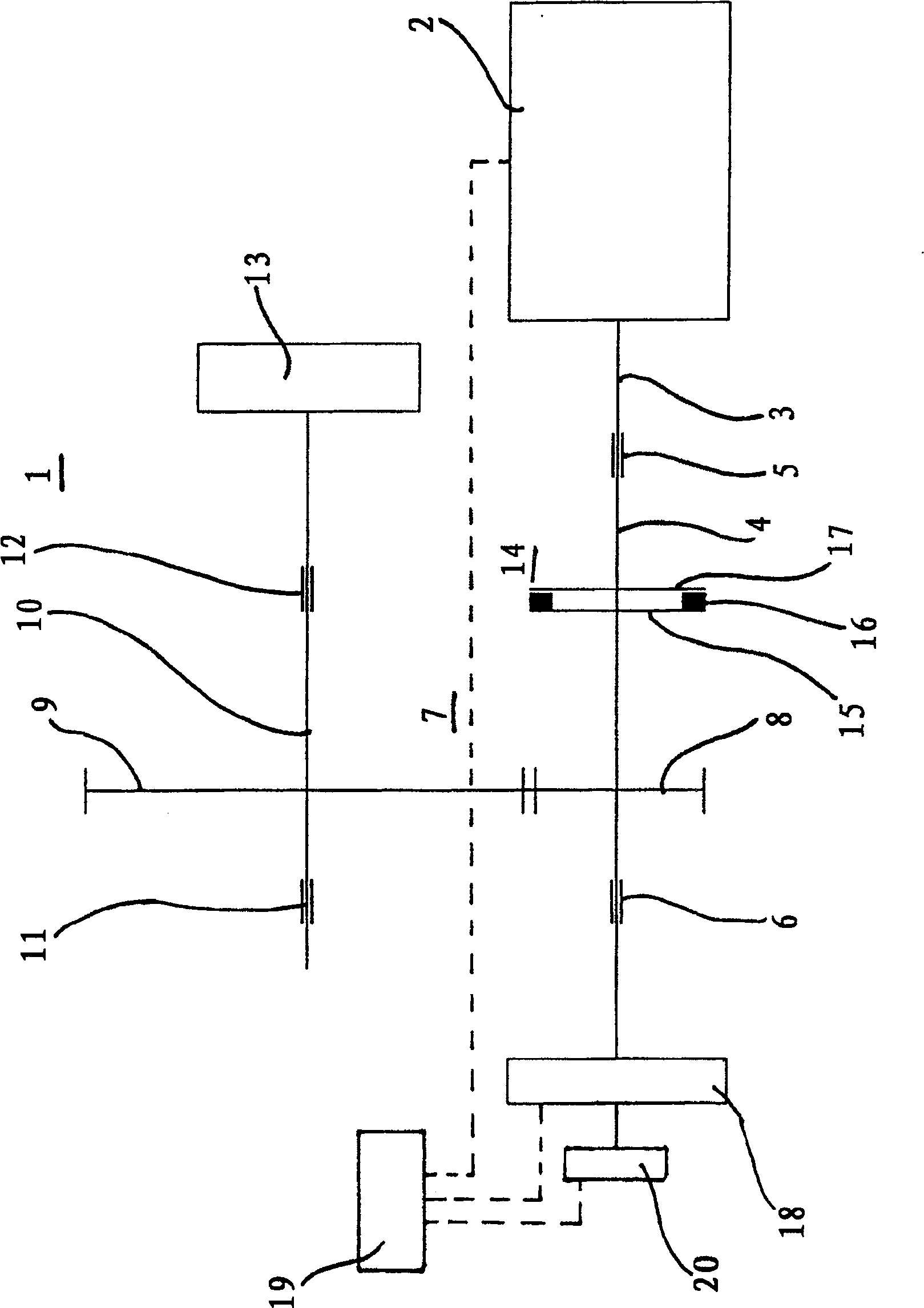

[0023] The chain blocks 1 have a drive motor 2 each having a motor shaft 3 protruding from the output of the drive motor 2 . The motor shaft 3 is arranged concentrically with the gearbox input shaft 4 and is connected to it in a rotationally fixed manner. The transmission input shaft 4 is supported in its end region by a first bearing 5 and a second bearing 6 , in particular designed as rolling bearings. The gearbox input shaft 4 is a component of the gearbox 7, which is designed as a single-stage in the exemplary embodiment shown, but can also be designed as a multi-stage. Gearbox 7 is mainly made up of gearbox input shaft 4, and a first gear 8 is installed between its bearings 5 and 6, and it meshes with a second gear 9. The second gearwheel 9 of the single gear stage of the gearbox 7 is mounted non-rotatably on the gearbox output shaft 10, the second gearwheel 9 is supported on both sides by a third bearing 11 and a fourth bearing 12, in particular designed as rolling be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com