Gas sensing dynamic testing device and gas sensing testing method

A technology of gas sensing and dynamic testing, which is applied in the direction of measuring devices, electrical components, and material analysis through electromagnetic means, and can solve the problems affecting the accuracy of material intrinsic testing, electromagnetic signal interference, and affecting the baseline and test data of test circuits Accuracy and other issues to achieve the effect of improving electrical shielding performance, ensuring accuracy and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

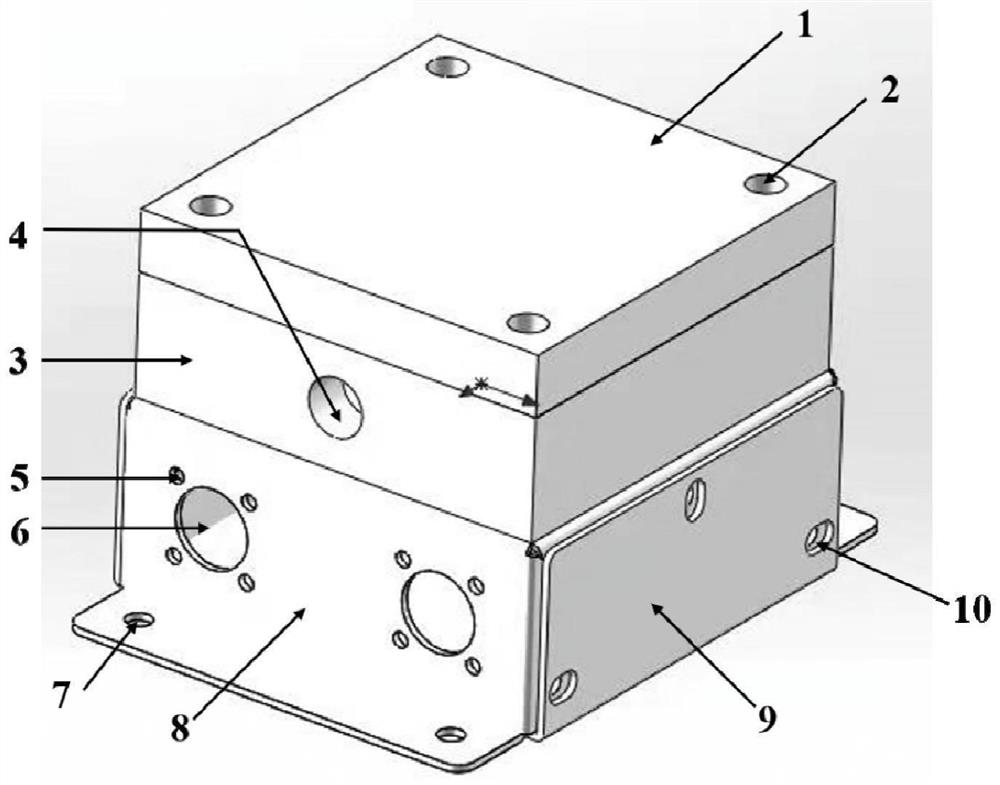

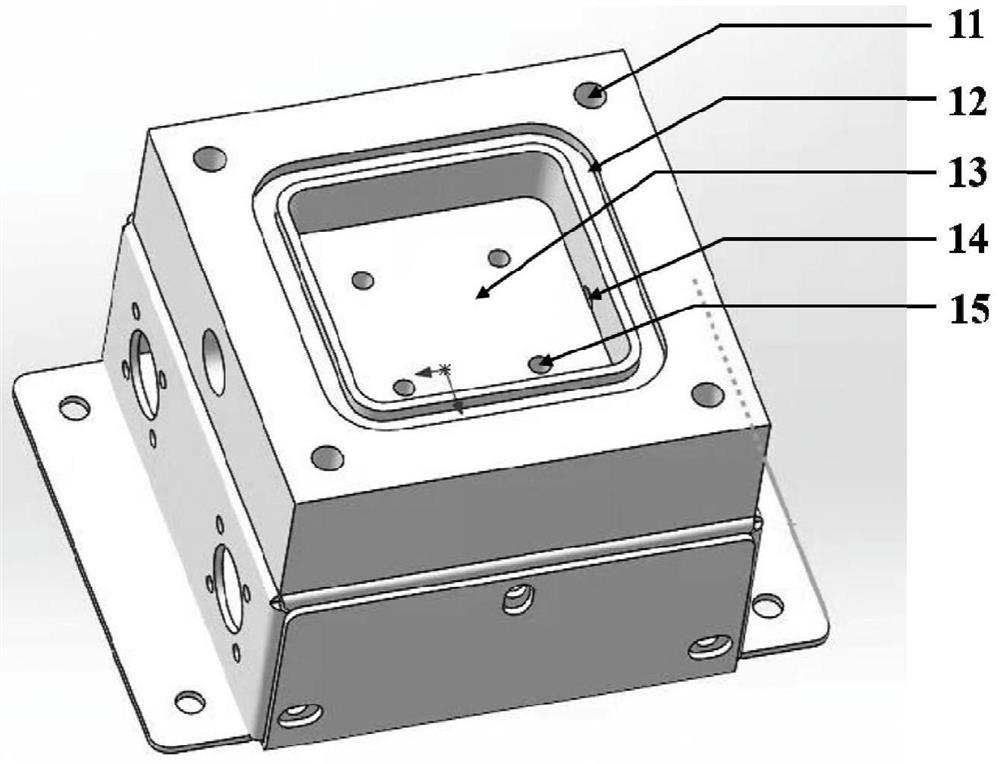

[0035] The present embodiment provides a gas sensing dynamic testing device, comprising a stainless steel upper cavity 3 and a stainless steel lower cavity, the stainless steel lower cavity is composed of a stainless steel plate 8 and a stainless steel plate 9 and the lower end surface of the stainless steel upper cavity 3; the stainless steel upper cavity The cavity 3 is provided with a stainless steel cover plate 1, and the stainless steel cover plate 1 and the stainless steel upper cavity 3 are sealed and connected by a sealing ring;

[0036] The side wall of the stainless steel upper cavity 3 is provided with an inlet hole 4 and an air outlet hole 14; the lower end surface is provided with 4 evenly distributed through holes 15;

[0037] The test module is fixed on the lower cavity through the BNC slot 6, the silver-plated copper wire passes through the through hole 15, one end is electrically connected with the two samples to be tested in the stainless steel upper cavity, a...

Embodiment 2

[0039] This embodiment provides a specific gas sensing dynamic testing device, such as figure 1 , figure 2 As shown, from top to bottom, the stainless steel cover plate 1 is connected to the stainless steel cavity 3 through the threaded hole 2 by screws with guide holes; a closed stainless steel cavity is constructed. A sealing ring is placed in the sealing groove 12 in the stainless steel cavity 3 to increase the sealing performance. Air intake holes 4 are opened on both sides of the cavity, and gas enters and exits through internal air outlet holes 14 .

[0040] In the lower part of the stainless steel sealed cavity, the stainless steel plate is fixed by threads on four sides to form an electromagnetic shielding box. The BNC electrical connectors are fixed on the steel plates on both sides through the electrode holes 15 by screws on both sides.

[0041] The BNC electrode head is connected with the electrodes in the electrode holes 15 through metal wires to form a test pa...

Embodiment 3

[0047] Before testing the sample, put the sample to be tested into the middle of the test chamber, connect it with the test electrode through the gold wire, then fix the stainless steel cover plate on the test chamber through threaded screws, and tighten the screws to make the upper stainless steel plate and stainless steel The cavity forms a closed system.

[0048] During the test, the gas to be tested is introduced from the air inlet, so that the gas enters the test chamber at a fixed flow rate and flows out from the air outlet. At this time, use the coaxial line through the BNC connector and the source meter to connect, record the input electrical signal and output electrical signal, and complete the test.

[0049] At a flow rate of 200 sccm, the gas enters and fills the entire chamber in less than 1 second, maximizing the contact between the gas and the sample, and effectively improving the test efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com