Manufacturing process of winding pin of network filter

A network filter and manufacturing process technology, which is applied in the direction of inductance/transformer/magnet manufacturing, coil manufacturing, electrical components, etc., can solve problems such as wire damage, low efficiency, pin deformation, etc., to reduce insulation layer failure or fracture, Optimize the inclination angle and avoid the effect of enameled wire damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

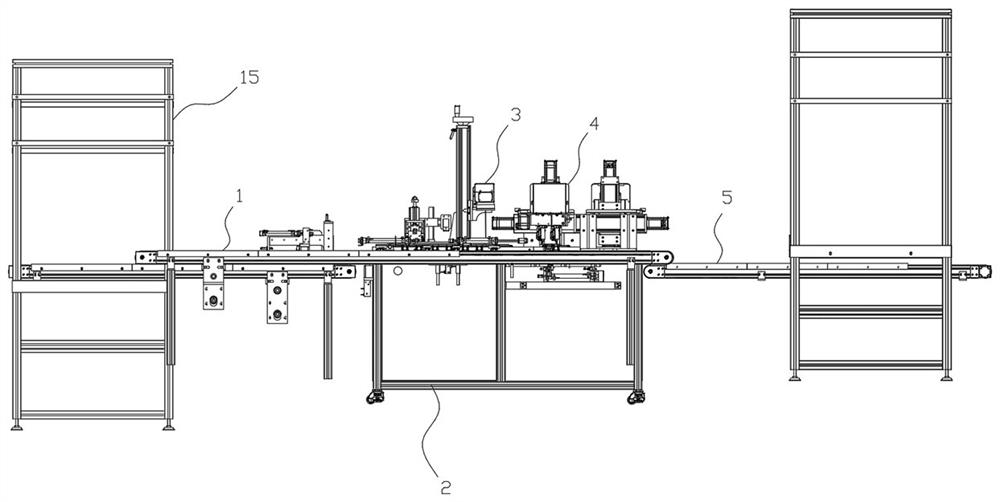

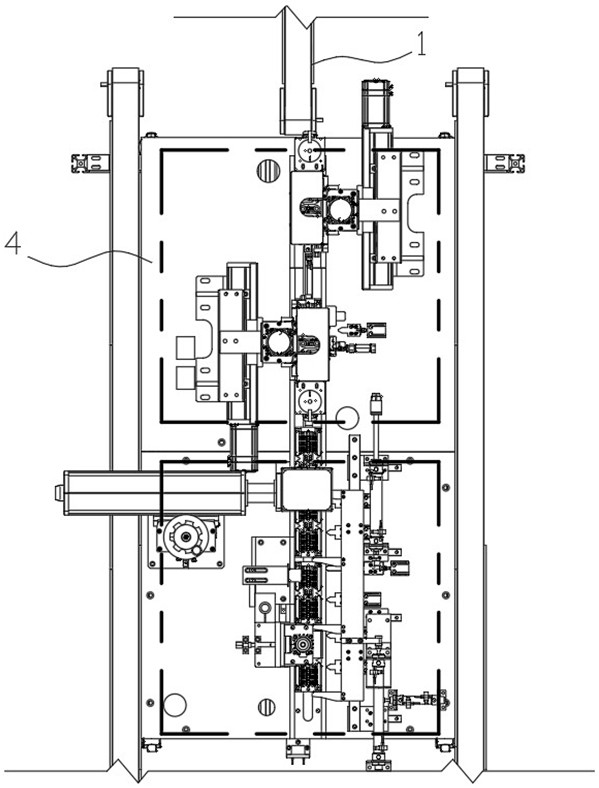

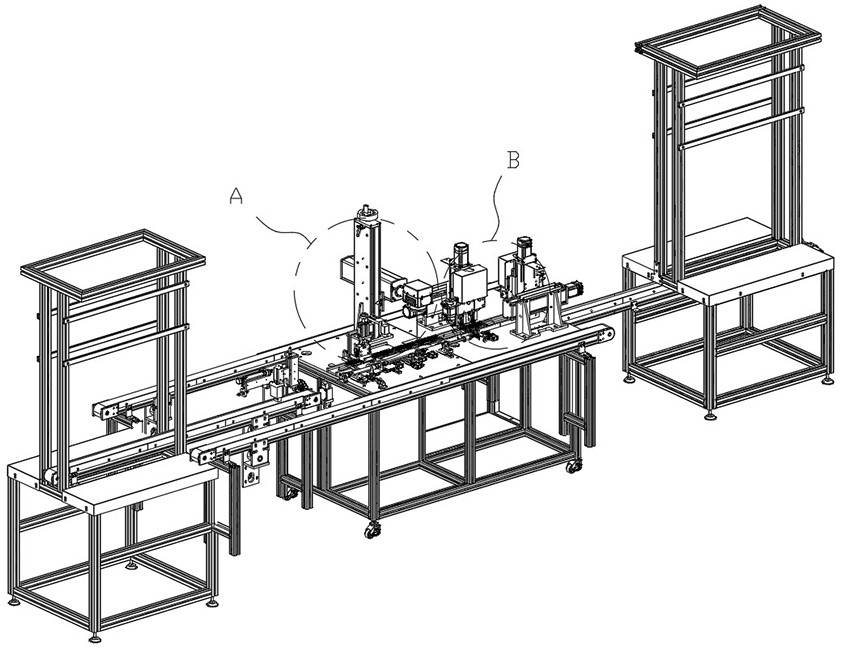

[0047] This embodiment discloses a manufacturing process of a network filter, which is mainly used for the foot-wrapping process of the network filter.

[0048] First, a brief description of the production process and corresponding products involved in the system in this embodiment is required, so as to support and explain the subsequent content.

[0049] The network filter is a miniature semiconductor component with a housing. There are several magnetic rings inside the housing. Single or multiple enameled wires are wound on the magnetic rings to form an inductive element, which is connected to an external circuit through pins to achieve corresponding technical effects.

[0050] At least two wire ends of enameled wires can be drawn from the magnetic ring, and the wire ends have a certain extension length. In the existing technology, after the magnetic ring is installed in the housing, the wire ends are drawn out of the housing as required. At this time, the pins on both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com