Common-box bus assembly method

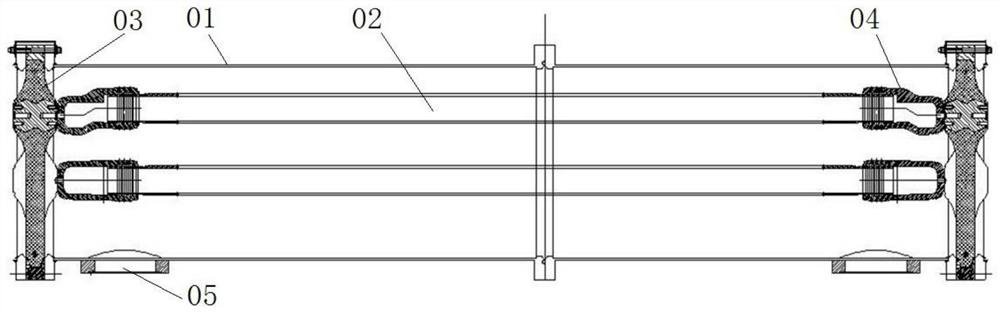

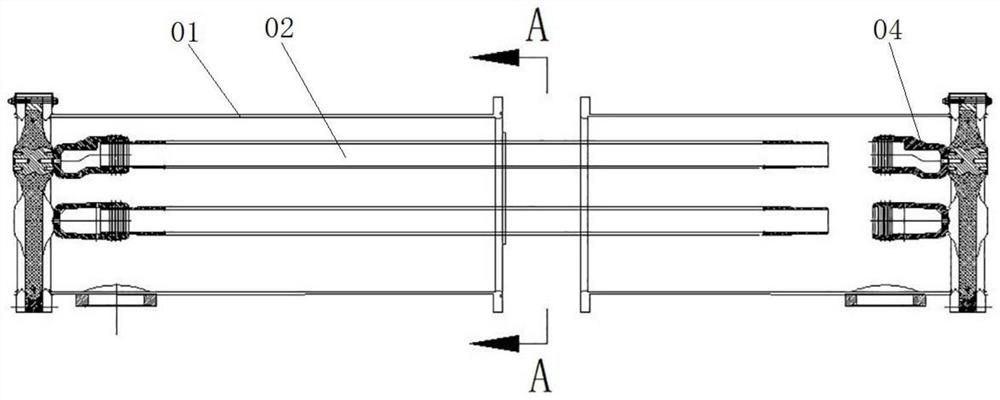

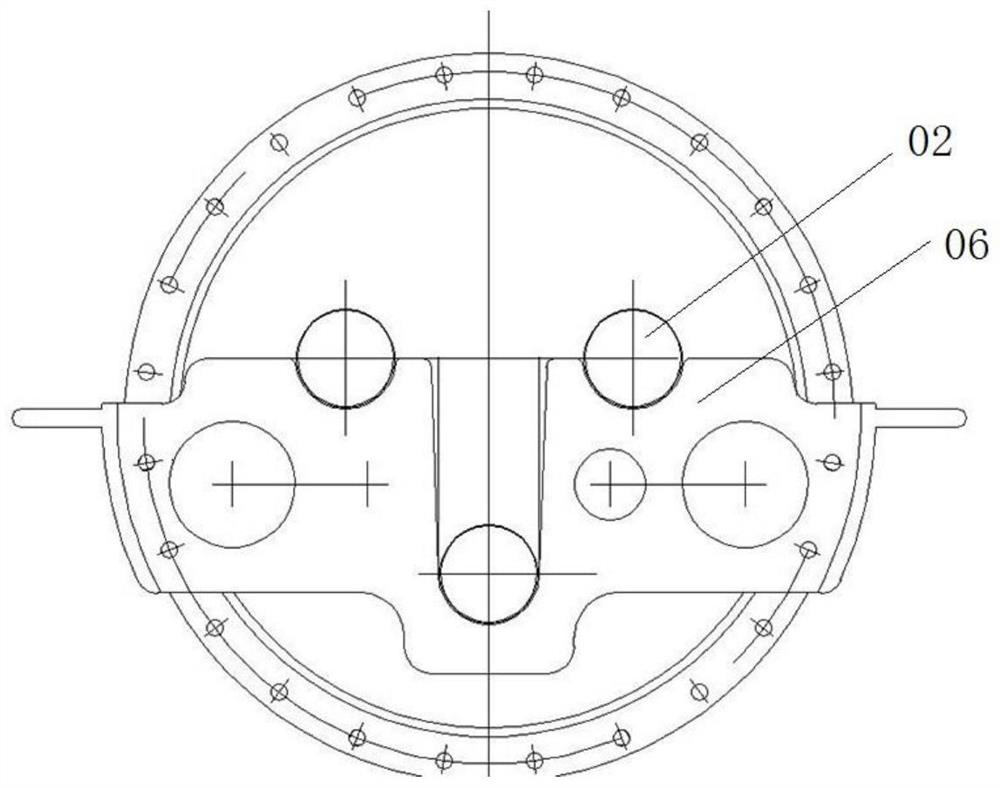

An assembly method and busbar technology, applied in the direction of fully enclosed busbar devices, etc., can solve problems such as poor installation of busbars, achieve the effects of improving work efficiency, improving product assembly quality, and simple and convenient assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The method for assembling the common box busbar includes steps:

[0067] Such as Figure 5 , Figure 6 , Figure 7 As shown, the first support insulator 031 is equipped with an insulator assembly support base 1, the insulator assembly support base 1 is a movable lifting base, the insulator assembly support base 1 has a moving base 11 and a lifting frame 12 arranged on the moving base 11, Mobile base 11 comprises frame body, and frame body comprises vertical rectangular frame and the leg that is positioned at the bottom of rectangular frame, and leg is provided with roller; The movable guide is assembled on the frame body, and the frame body is provided with a hydraulic lifting mechanism, which drives the lifting frame 12 to lift; Bearings are provided to rotatably assemble the rotating shaft 14 on the support 13 .

[0068]Turning connecting plate 15 is fixed on rotating shaft 14, and turning connecting plate 15 is provided with the fixing hole that is arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com