Equipment and method for preparing roller

A roll and equipment technology, applied in the field of roll preparation equipment, can solve the problems of roll layer structure segregation, coarse eutectic carbide, loose structure, etc., and achieve the effect of improving coarse structure, uniform solidified structure, and reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

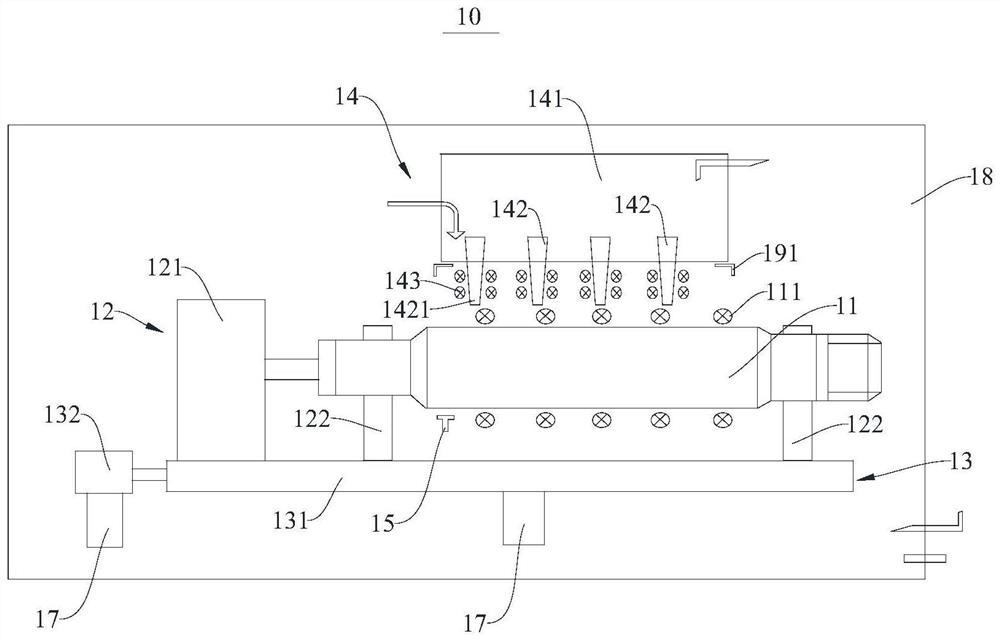

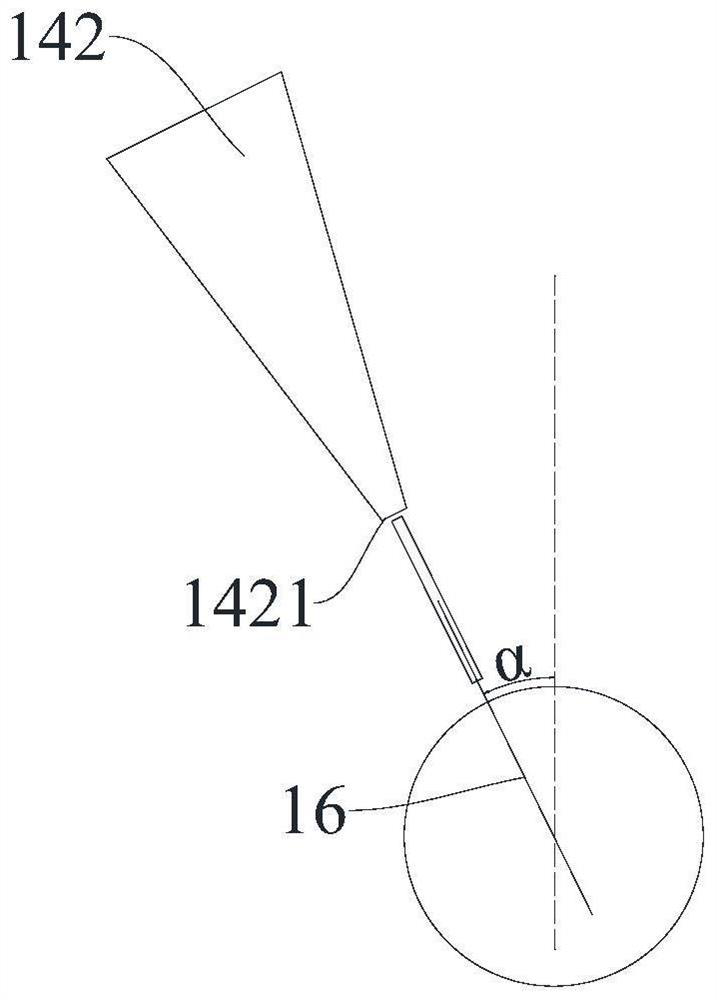

[0034]When the equipment 10 for preparing rolls in the embodiment of the present application is in use, the rotating mechanism 12 drives the mandrel 11 to rotate around the axis of rotation, and the translation mechanism 13 drives the rotating mechanism 12 and the mandrel 11 to move linearly along the extension direction of the axis of rotation synchronously. Simultaneously, the injection mechanism 14 sprays the molten metal from the injection port 1421 onto the surface of the mandrel 11. During the rotation and translation of the mandrel 11, the molten metal can be evenly distributed on the surface of the mandrel 11, and the cooling mechanism 15 The metal on the surface of the injection mandrel 11 is cooled and solidified to form a roll. Wherein, when the equipment 10 for preparing rolls in the embodiment of the present application is in use, the molten pool is limited between the bottom surface of the nozzle 142 and the mandrel 11, and the bottom surface of the nozzle 142 act...

Embodiment 1

[0059] This embodiment provides a method for preparing rolls, which utilizes the equipment 10 for preparing rolls in the embodiment of the present application to prepare rolls, including the following steps:

[0060]Vacuumize the vacuum chamber 18 and feed inert gas into the crucible 141 with molten metal so that the pressure in the crucible 141 is 0.15 MPa higher than the pressure in the vacuum chamber 18; wherein the molten metal The insulation temperature is 1530°C.

[0061] Preheat the mandrel to a temperature of 1080°C, drive the mandrel 11 to rotate around the rotation axis at a speed of 120 r / min through the rotation mechanism 12, and at the same time, the translation mechanism 13 drives the rotation mechanism 12, and the mandrel 11 rotates at a speed of 12 cm along the extension direction of the rotation axis. / min speed linear motion, lifting mechanism 17 drives translation mechanism 13, rotation mechanism 12 and mandrel 11 to descend with the speed of 10mm / min; Where...

Embodiment 2

[0066] This embodiment provides a method for preparing rolls. The only difference from Embodiment 1 is that the composition of the metal melt in this embodiment is high-speed steel-2, and the rotation speed of the mandrel 11 is 100r / min. 11. The speed of linear motion along the extension direction of the rotation axis is 10cm / min. The holding temperature of the metal melt is 1510°C.

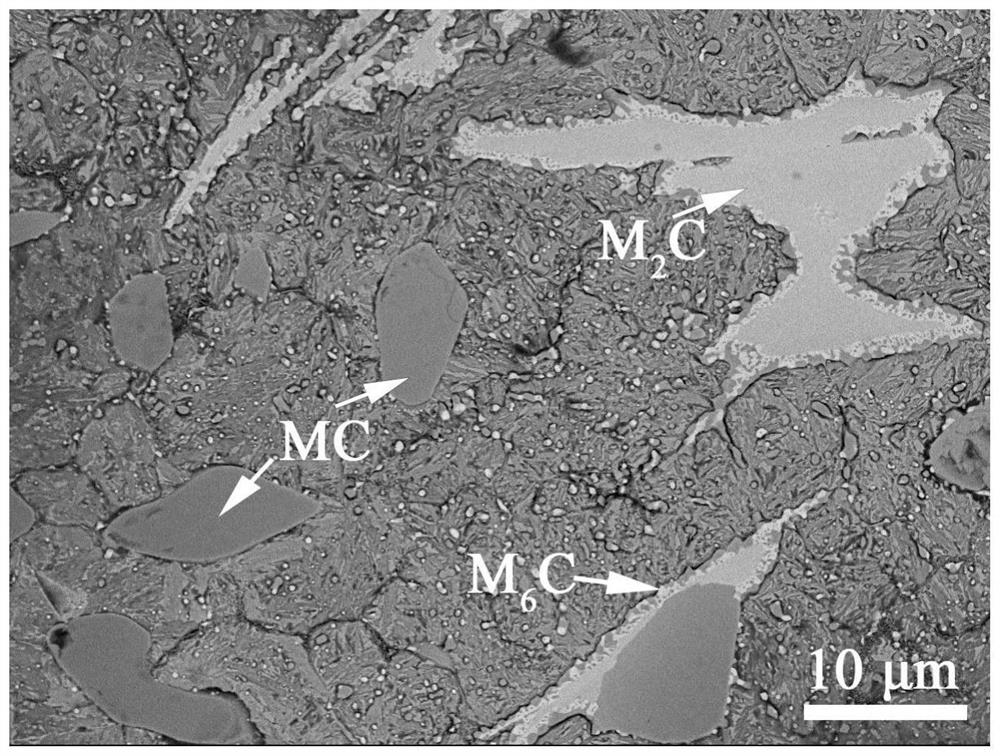

[0067] The carbides in the outer layer of the roll prepared in this example are evenly distributed, and no obvious network carbides are seen. The tissue is dense, and no pores visible to the naked eye are found. Among them, the average grain size of carbides is 8 μm, along the radial direction of the roll, the hardness of the outer layer of the roll fluctuates little, and the change trend is the same as that of Example 1, and the microhardness is maintained at 800-850HV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com