Friction stir welding aluminum alloy ship bottom plate

A technology of friction stir welding and aluminum alloy, which is applied in the direction of hull paneling, hull double bottom, hull, etc., can solve the problems of complex underwater structure, the influence of ship hazards, and the inability to quickly lock the position of collision damage, etc., to achieve fast The effect of positioning the collision position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

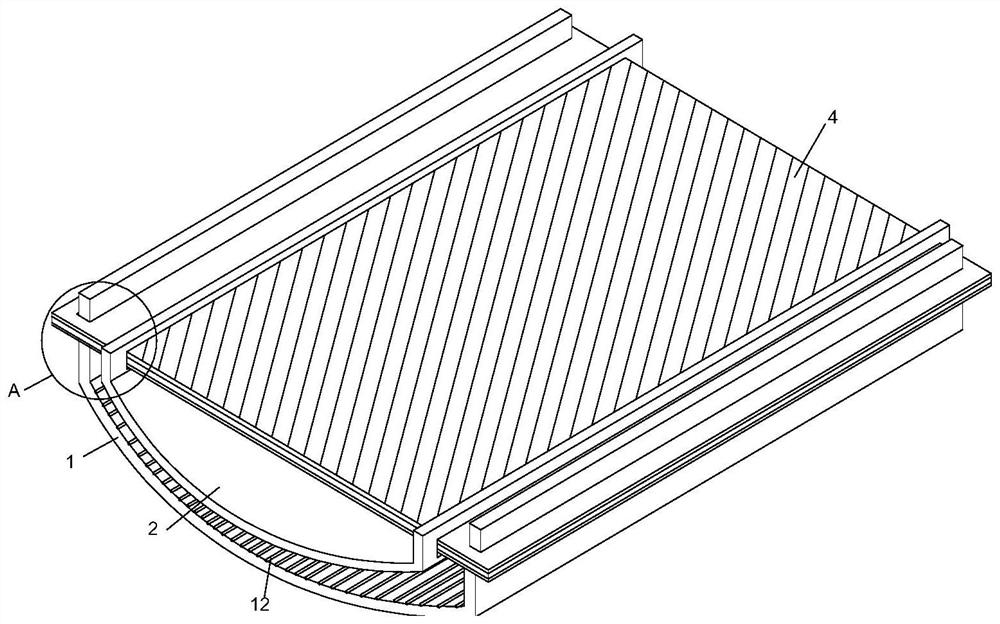

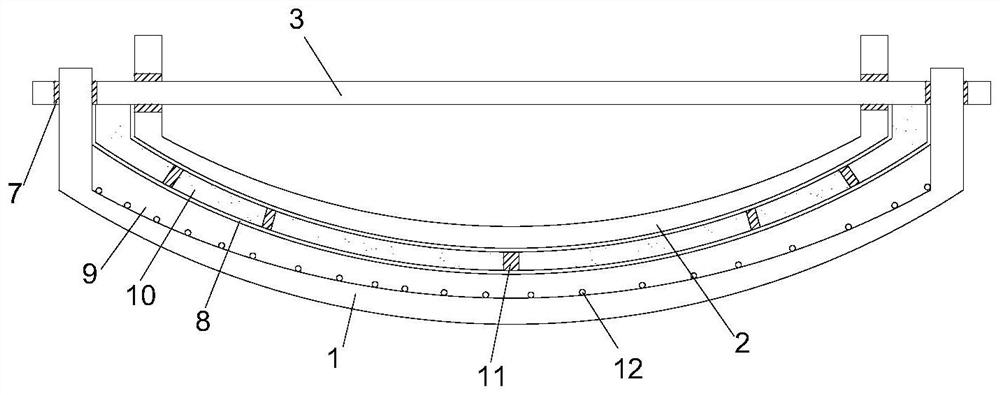

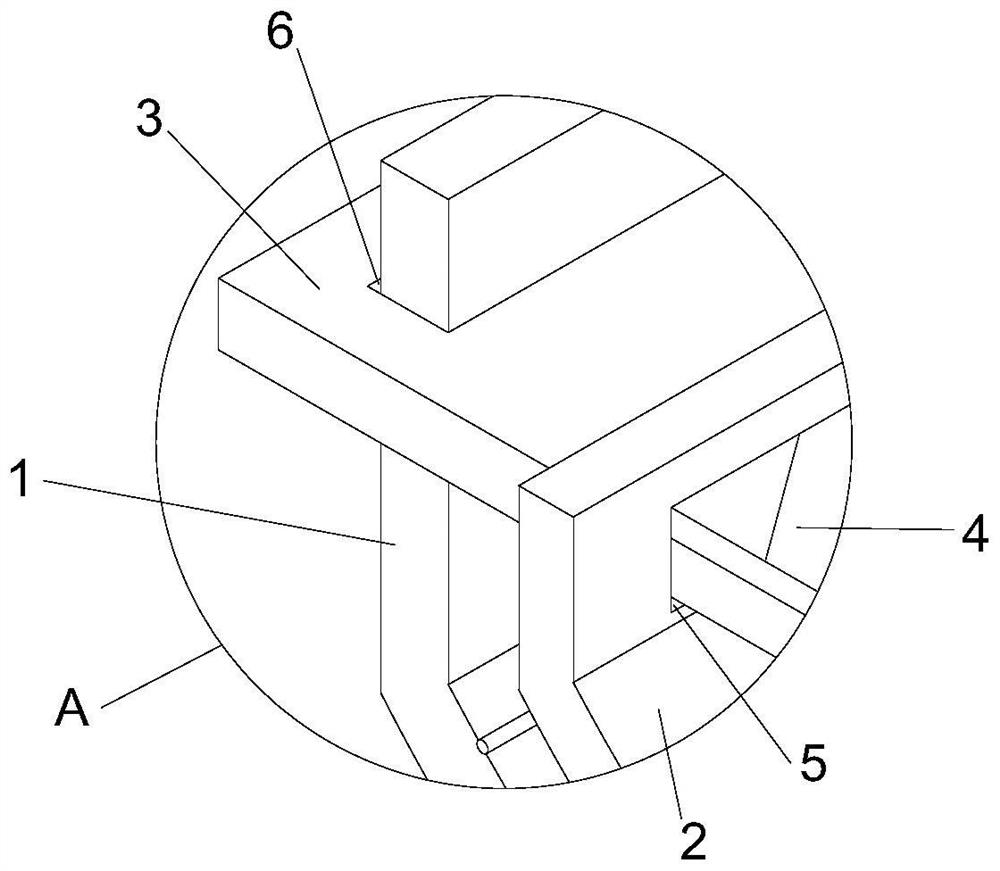

[0029] Embodiment: a kind of friction stir welding aluminum alloy ship bottom plate, such as Figure 1-Figure 4As shown, including the outer protective plate 1 and the inner protective plate 2, the outer protective plate 1 and the inner protective plate 2 are plates of arc structure, the inner protective plate 2 is arranged inside the outer protective plate 1, the outer protective plate 1 and the inner protective plate A gap is formed between the plates 2, the top surface of the outer protective plate 1 and the inner protective plate 2 is provided with a bottom plate 3, the top surface and the bottom surface of the bottom plate 3 are sprayed with an anti-corrosion coating 4, and the side wall surface of the inner protective plate 2 is close to the upper surface. There are left and right symmetrical welding openings 5 penetrating through the side position, and the two sides of the bottom plate 3 respectively pass through the corresponding welding openings 5 and extend to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com