Surface protective film

A technology of surface protection film and base film, which is applied in the direction of film/sheet adhesive, non-polymer adhesive additive, adhesive type, etc., can solve the problem that it is impossible to use acetylacetone, etc., and achieve optical improvement The effect of the characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

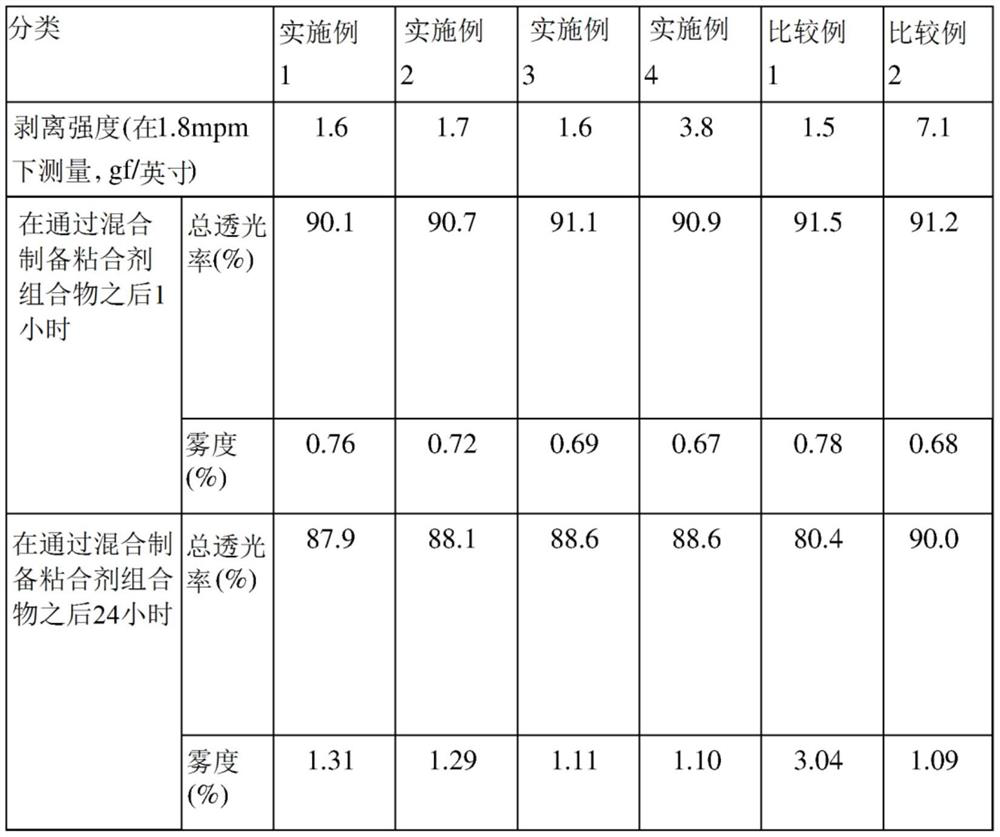

Examples

Embodiment 1

[0074] (1) Composition for forming an adhesive layer

[0075] A 2L 5-neck glass reactor equipped with a reflux condenser was prepared, and then 764 g of bifunctional polyol SC-2204 (Mn-2,000 g / mol, KPX Chemical Co., Ltd.) and 110 g of dicyclohexamethylene were placed therein diisocyanate (H12MDI, Evonik), and then sequentially added thereto 300 g of 2-ethylhexyl acrylate (2-EHA, LG Chem.) and 300 g of lauryl acrylate (M120, Miwon Specialty Chemical Co., Ltd.). After the addition was complete, the mixture was heated to 70°C and kept at 70°C while stirring at a speed of 100 rpm to become homogeneous. At the same temperature, 50 ppm DBTDL was added to the mixture to initiate the reaction to form NCO prepolymer, and the mixture was kept at 78°C to 82°C for 3 hours. Thereafter, 26 g of 2-HEA (Nippon Shokubai Co., Ltd.) was added to the mixture, and then the mixture was reacted at 80° C. for 3 hours until the FT-IR NCO peak (2,260 cm -1) disappeared, thereby producing a urethane-b...

Embodiment 2

[0081] A surface protection film was produced in the same manner as in Example 1 except that acrylic acid was used in an amount of 0.8 parts by weight in preparing the adhesive composition.

Embodiment 3

[0083] A surface protection film was manufactured in the same manner as in Example 1 except that acrylic acid was used in an amount of 1.2 parts by weight when preparing the adhesive composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com