Gas distribution system and gas distribution method

A gas distribution and gas technology, which is used in chemical instruments and methods, gas and gas/vapor mixing, mixers, etc., can solve the problems of long-time flushing of the detection chamber, affecting the test speed and accuracy, etc., to improve the dilution ratio, The effect of shortening the gas distribution time and improving the control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

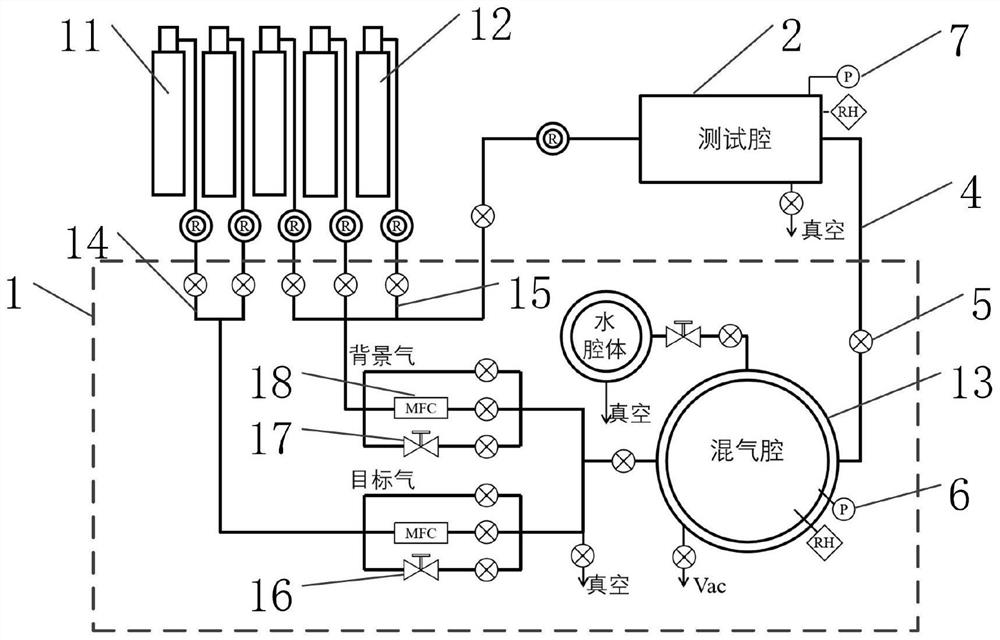

[0049] Such as figure 1 As shown, the embodiment of this specification provides a gas distribution system, including a gas distribution assembly 1, a test chamber 2 and a vacuum pump. The gas distribution assembly 1 includes a background gas cylinder 12, a mixing chamber 13 and at least one target gas cylinder 11. The target gas The bottle 11 communicates with the mixing chamber 13 through the corresponding target gas path 14, and the background gas cylinder 12 communicates with the mixing chamber 13 through the background gas path 15. The target gas path 14 is provided with a first valve 16, and the background gas path 15 is provided with a second valve. Two valves 17, one end of the test chamber 2 communicates with the mixing chamber 13 through the ventilation pipeline 4, the ventilation pipeline 4 is provided with a third valve 5, the other end of the testing chamber 2 is connected to a vacuum pump, and the vacuum pump is used to evacuate the mixing chamber 13, The mixing c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap