Accurate preparing and adding device for special additive for methanol gasoline

A technology of methanol gasoline and adding devices, which is applied in the direction of transportation and packaging, mixer accessories, mixers, etc., can solve the problems of inaccurate solution volume and residual solution, and achieve the effect of increasing accuracy and preventing deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

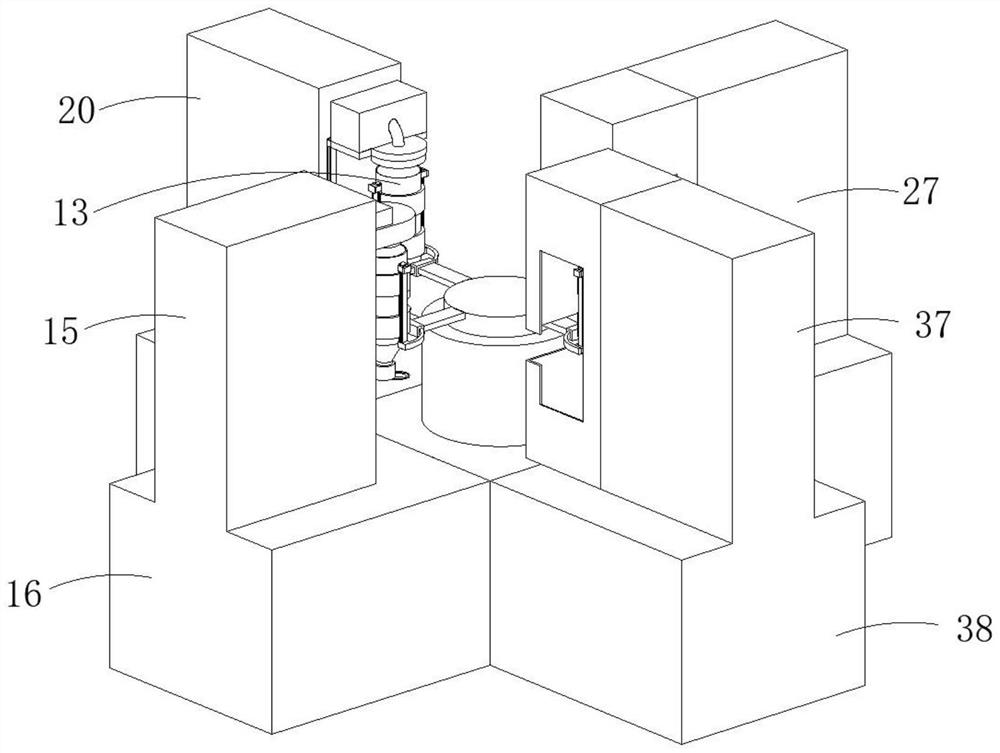

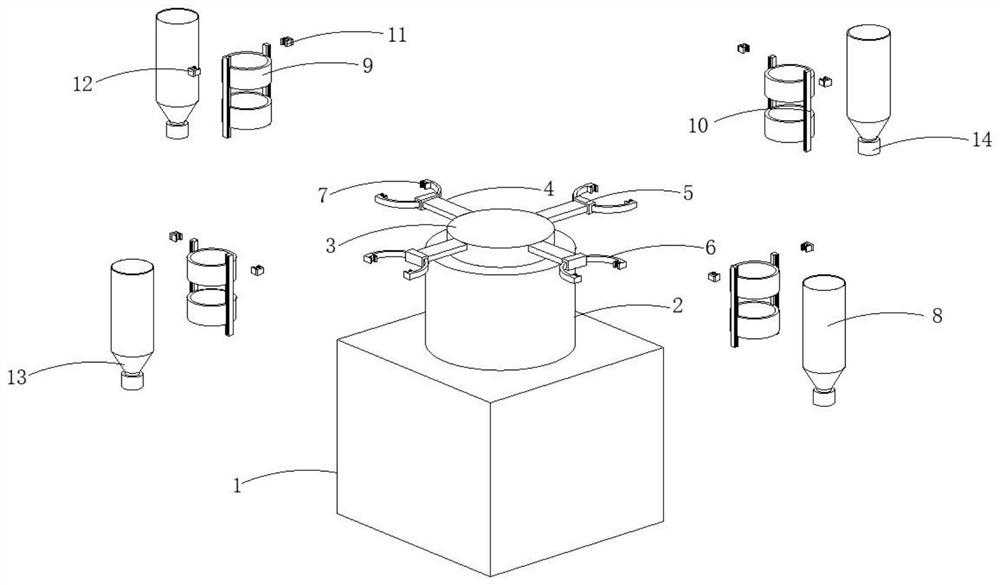

[0029] The present invention provides such figure 1 As shown, a precise preparation and adding device for methanol gasoline special additives, including a fixed base 1, a liquid injection tank 15, a feeding box 20, a cleaning box 27 and a drying box 37, and a control box 2 is arranged on the upper part of the fixed base 1 , the top of the control box 2 is movably installed with a rotating plate 3, and the outer surface of the rotating plate 3 is equidistantly provided with an arc-shaped splint 6, and the inside of the arc-shaped splint 6 is movable and installed with a measuring cylinder 8, and the outer surface of the measuring cylinder 8 is fitted with a positioning sleeve 9 symmetrically up and down. , the two sides of the positioning sleeve 9 are fixedly installed with the corresponding arc splint 6 with the second limit block 10; the bottom of the liquid injection tank 15 is connected with the storage tank 16, the bottom of the feed tank 20 is connected with the configurat...

Embodiment 2

[0034] It is worth noting that a liquid outlet plate 17 is connected to the output end of the liquid injection tank 15, and an electric control valve 19 is connected to the upper part of the liquid outlet plate 17. The box 15 and the storage box 16 are connected and installed so that the liquid in the storage box 16 can be output to the liquid outlet plate 17 through the liquid injection box 15, and the top of the measuring cylinder 8 is injected through the docking port 18, and the liquid is controlled by the electronic control valve 19 provided. Quantity, to achieve the accuracy of the material, such as Figure 4 shown.

[0035]Further, the front side of the feeding box 20 is symmetrically provided with a first chute 23, and the first chute 23 is externally engaged with a first movable plate 24, and the bottom of the first movable plate 24 is provided with a sealing interface corresponding to the position of the measuring cylinder 8. 25. The upper surface of the first movab...

Embodiment 3

[0037] Preferably, the front side of the cleaning box 27 is left and right symmetrically provided with a second chute 30, the outer surface of the second chute 30 is movably clamped and installed with a second movable plate 31, and the front side of the second movable plate 31 is fixedly mounted with a pressing plate symmetrically 32. The upper surface of the waste liquid tank 28 is connected with the second liquid outlet port 29 corresponding to the position of the docking bayonet 14. The upper part of the front pressure plate 32 of the cleaning box 27 is connected with a water spray port 35. The second chute is controlled by setting the cleaning box 27 30 and the second movable plate 31 cooperate to move, so that the pressure plate 32 pushes down the measuring cylinder 8 to contact the second liquid outlet interface 29, and after the water is sprayed out through the water spray port 35, it flows back to the waste liquid tank 28 through the second liquid outlet interface 29 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com