Scraper-free selective laser melting additive manufacturing process

A laser selective melting and additive manufacturing technology, applied in manufacturing tools, additive processing, solid material additive processing, etc., can solve the problems of parts printing failure, stuck scraper, etc., to reduce workload, high commercial value, Realize the effect of engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] This embodiment shows a scraperless laser selective melting additive manufacturing process, and parts are prepared through the scraperless laser selective melting preparation structure;

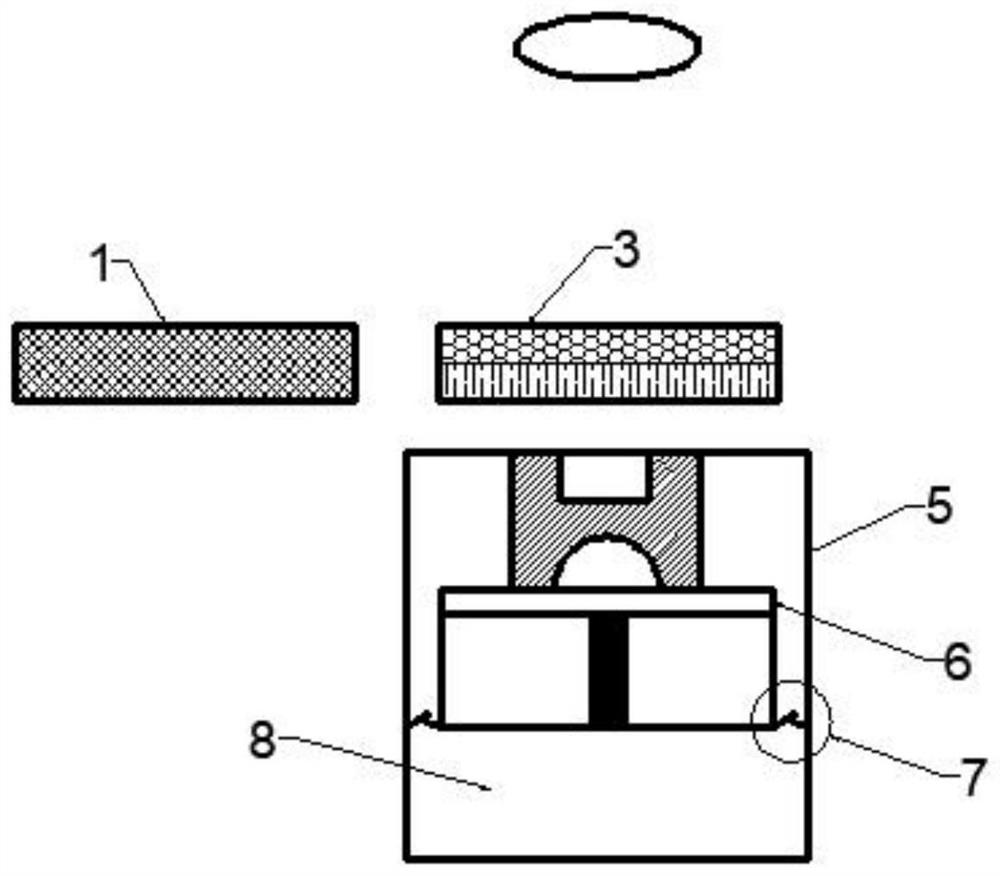

[0029] refer to figure 1 The non-scraper-type laser selective melting preparation structure 100 includes a molding substrate 6 arranged in the molding chamber 5. The top of the molding chamber 6 is correspondingly provided with a laser generator 21 for emitting a laser beam 2, and the molding chamber 6 is also correspondingly provided with a powder feeding Device 3 and powder pressing plate 1;

[0030] The molding steps are:

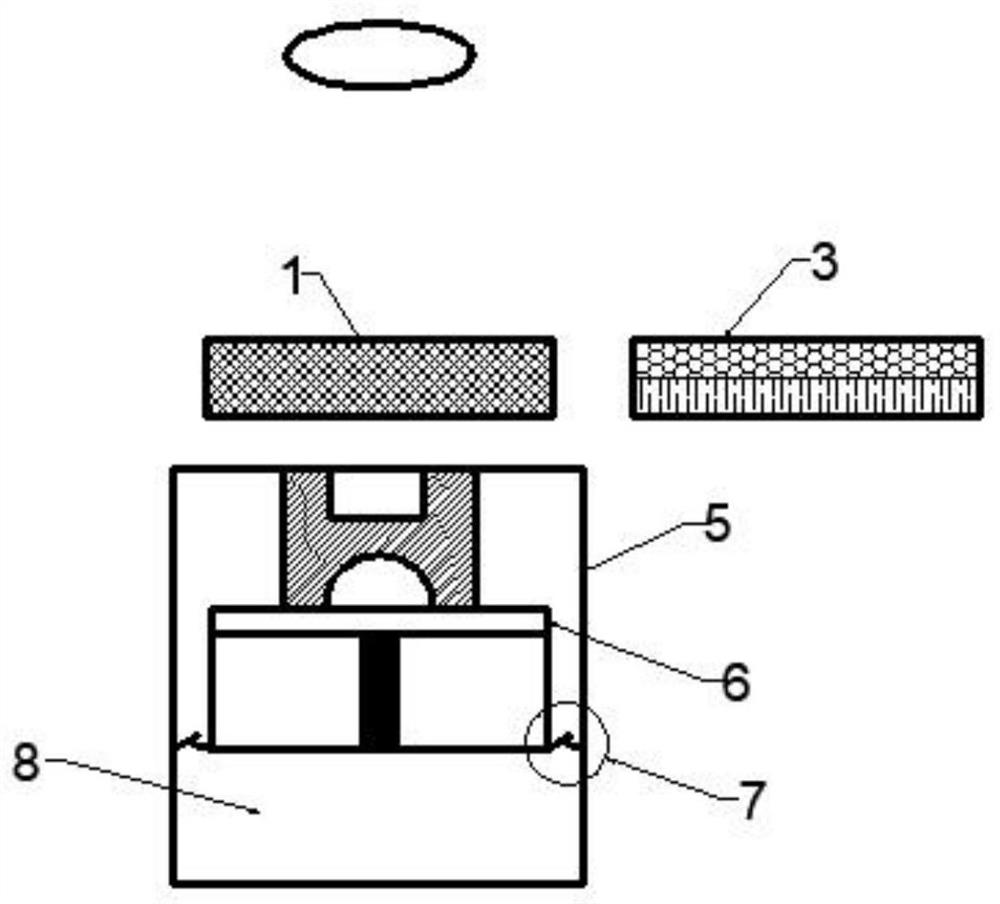

[0031] 1) Refer to figure 2 , the powder feeding device 3 sends the molding material powder to the molding substrate 6, and then resets;

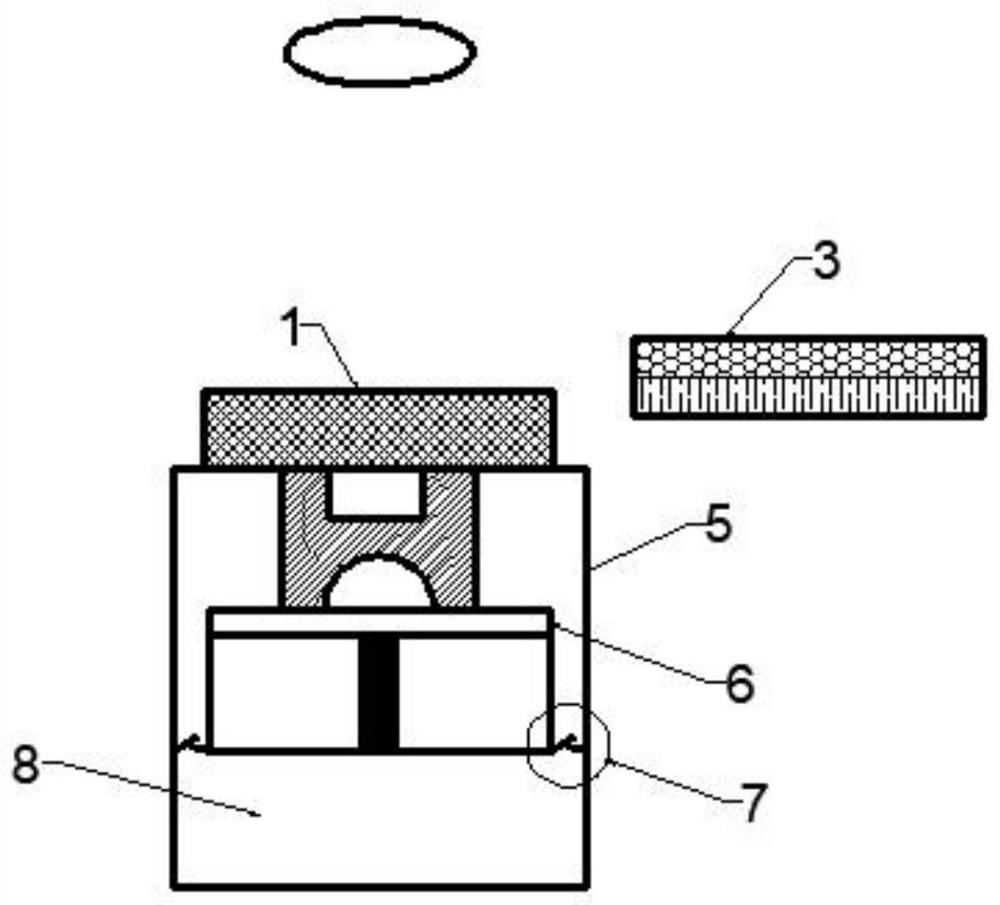

[0032] 2) Refer to image 3 , the powder pressing plate 1 compacts the molding material powder on the molding substrate, and then resets;

[0033] 3) Refer to Figure 4 , the laser emitter 21 emits the laser beam 2 to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com