Speed feedback type small laser welding machine

A laser welding machine and speed feedback technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of affecting welding quality, impenetrable workpiece welding, and small heat input, so as to save the need to wear protective glasses , Prevent sparks from splashing and improve welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

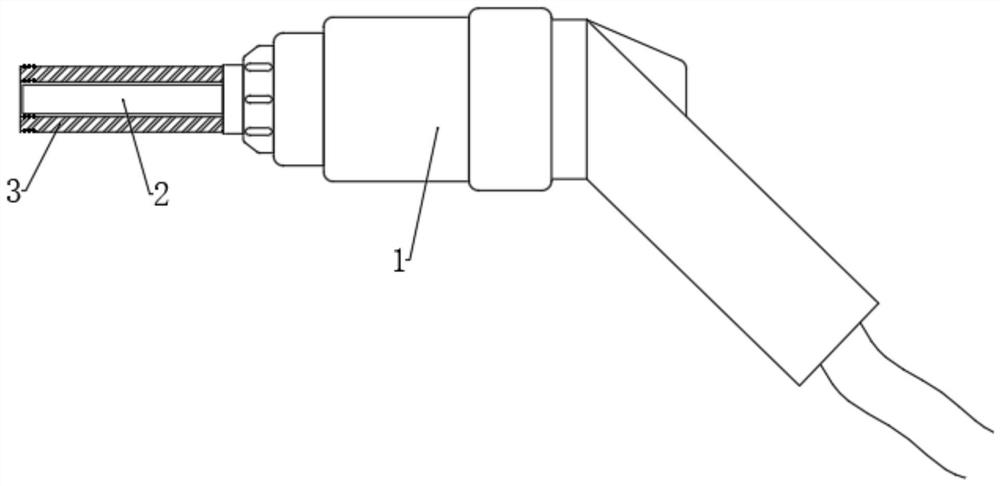

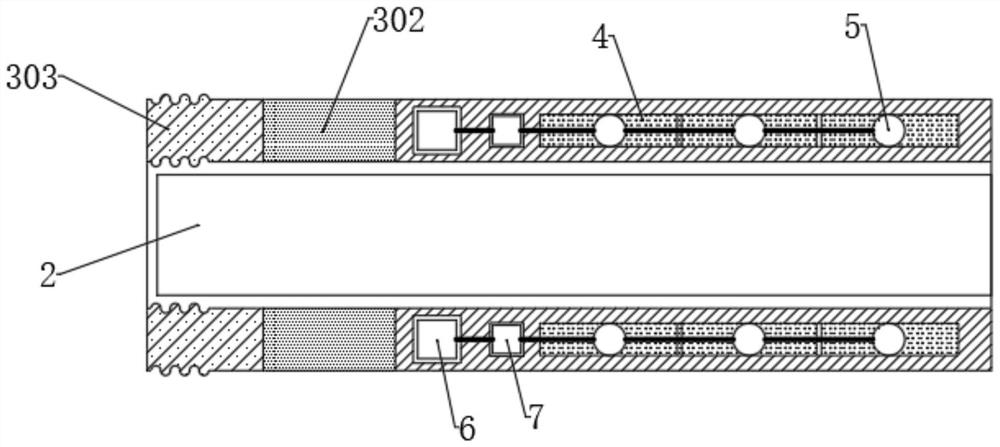

[0046] see Figure 1-8 , a speed feedback small laser welding machine, including a welding machine body 1, please refer to figure 1 , the welding head 2 is connected to the welding machine body 1, the feedback sleeve 3 is connected to one end of the welding machine body 1, and the feedback sleeve 3 is set on the outside of the welding head 2, and the length of the feedback sleeve 3 is greater than the length of the welding head 2 , is to ensure that the feedback sleeve 3 can cover the welding point and the feedback sleeve 3 is connected to the welding machine body 1 through threads, which is convenient for disassembly and installation;

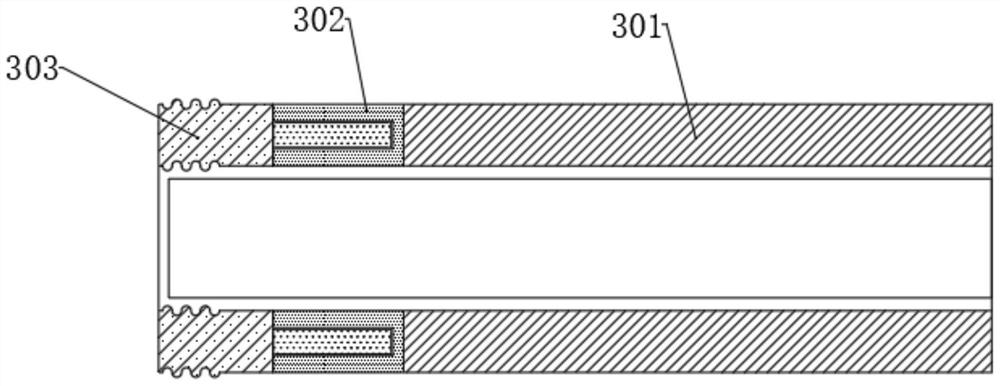

[0047] see figure 2 , 4 , 5. The feedback sleeve 3 includes a feedback section 301, a weak light section 302 and a blocking section 303. The side wall of the weak light section 302 away from the feedback section 301 is provided with an annular thread groove 3021, and the side wall of the blocking section 303 is fixedly connected with The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com