Device and method for driving torpedo anchor through spiral dumping

A technology for torpedo anchors and soil dumping, which is used in anchor points, transportation and packaging, ship construction, etc., can solve the problems of insufficient initial penetration depth of torpedo anchors, inability to fully exert the bearing capacity of torpedo anchors, and loose penetration of soil layers. The effect of saving transportation and installation costs, reducing forward propulsion resistance, and reducing material usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

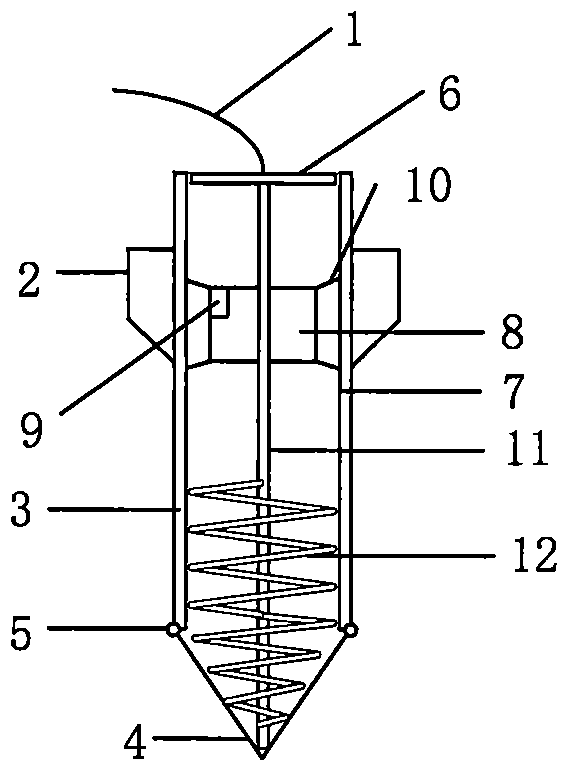

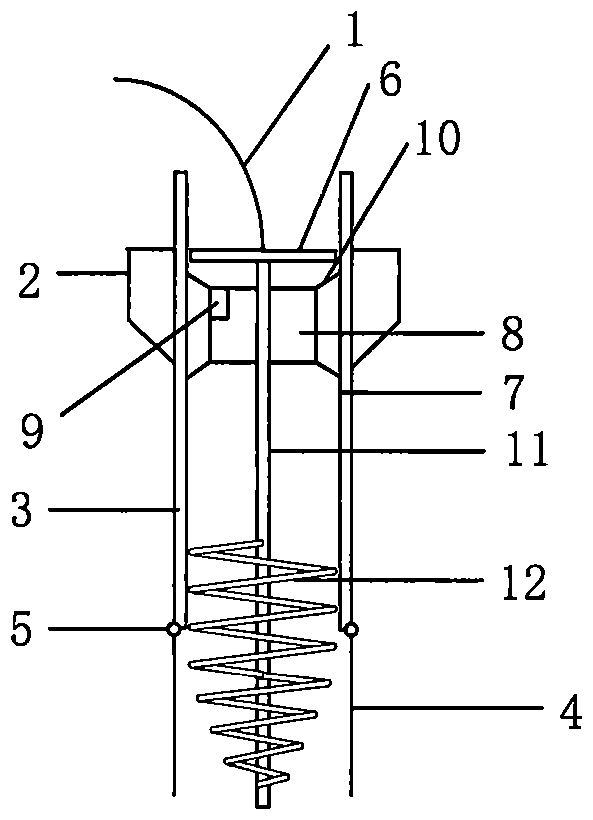

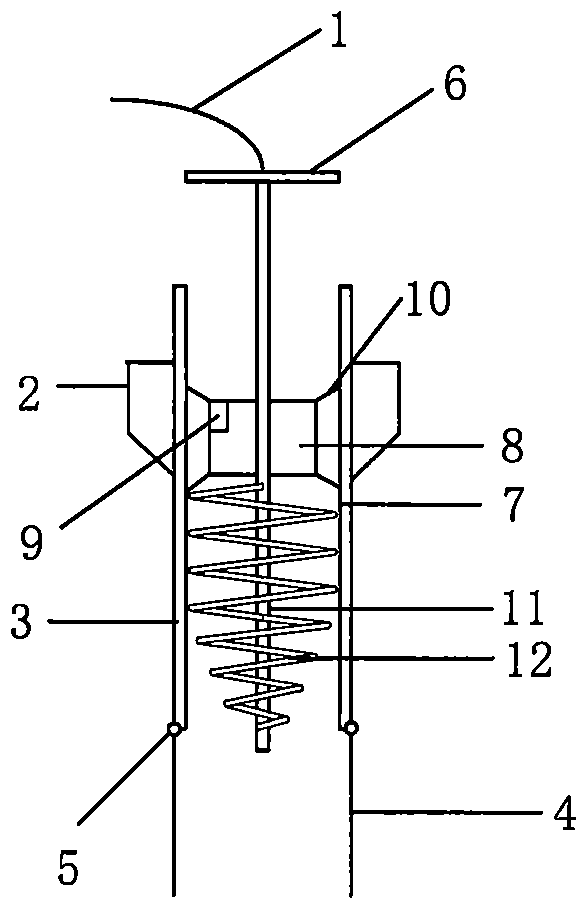

[0039] Such as figure 1 As shown, a device for driving a torpedo anchor by spiral dumping includes an anchor chain 1, an empennage 2, an anchor body 3, an anchor head 4, a hinge point 5, a tail plate 6, a hollow pipe 7, a stepping motor 8, a battery 9, Steel bar 10, rotating shaft 11, spiral plate 12;

[0040] The anchor body 1 and the anchor head 4 are connected by a hinge point 5;

[0041] The anchor chain 1 is connected to the external midpoint of the tail plate 6;

[0042] The battery 9 is installed inside the stepper motor 8;

[0043] The empennage 2 is welded to the tail of the anchor body 3 in a cross-shaped arrangement;

[0044] The tail plate 6 is welded together with the rear end of the rotating shaft 11, and is installed in the center of the hollow pipe 7. The diameter of the tail plate 6 is consistent with the inner diameter of the hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com