Unloading valve and combination valve type buffer oil cylinder

A buffer cylinder and unloading valve technology, which is applied in the field of hydraulic cylinders and hydraulic valves, can solve the problems of reducing the mechanical collision strength of cylinder pistons, misoperation of buffer valves, and reducing buffering effects, so as to avoid power consumption and system heating, and buffer control The effect of stability and outstanding cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

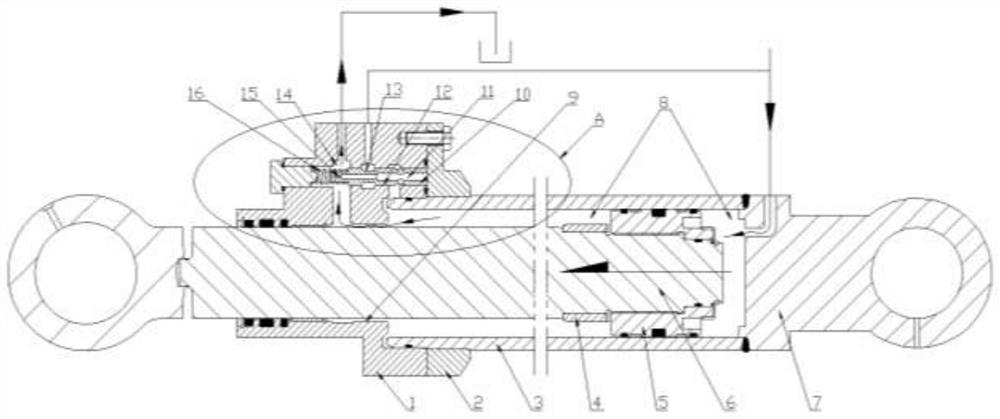

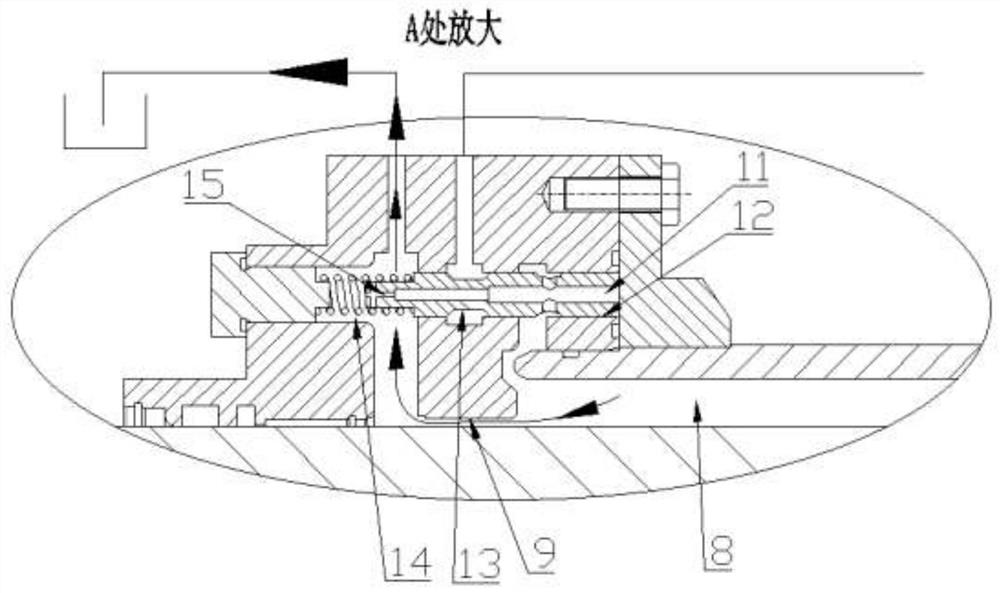

[0057] like Figure 1-4 As shown, a kind of unloading valve, the unloading valve is integrated on the guide sleeve of the oil cylinder, used in conjunction with the oil cylinder, can realize the unloading and buffering function of the oil cylinder, including the valve body, the valve core 10 and the return spring 16, the valve body is equipped with There is a valve hole 12, and the valve core is fitted in the valve hole. A driving cavity 11 of the valve core and a spring cavity 14 of the valve core are respectively formed at both ends of the valve hole. The return spring is arranged in the spring cavity, and one end thereof is compressed against At the bottom of the spring cavity, the other end is compressed against one end of the valve core, and under the thrust of the return spring, the other end of the valve core is pressed against the bottom of the drive cavity; the valve core is also provided with a damping hole 15 And the unloading groove 13, the driving chamber of the v...

Embodiment 2

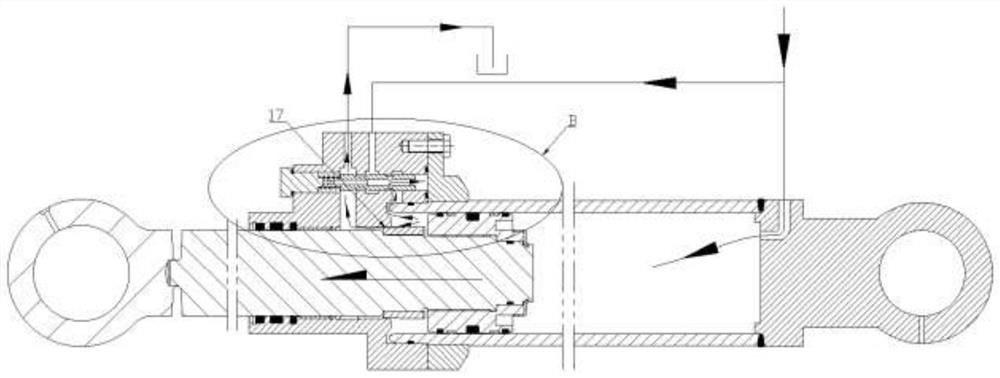

[0064] like Figure 5 , Image 6 As shown in the figure, a combination valve type cushioning oil cylinder is provided with a combination valve only in the cylinder chamber at one end of the cylinder bottom, and the combination valve is integrated on the bottom of the cylinder, which can realize the cushioning of the oil cylinder at the bottom end of the cylinder. Figure 5 and Image 6 The structure is similar, only the location of the unloading valve is different. Compared with Example 1, the main difference is that: the valve hole of the unloading valve and the buffer chamber of the throttle valve are set on the bottom of the cylinder, and the buffer plug of the throttle valve is set at the center of the bottom of the piston rod. Similar to Example 1, it will not be repeated here.

Embodiment 3

[0066] like Figure 7 As shown, a combination valve type buffer oil cylinder is equipped with combination valves at both ends of the oil cylinder, which can realize the buffer when the piston at any end of the oil cylinder is close to the end of the cylinder stroke. This embodiment is a composite structure of Embodiment 1 and Embodiment 2, which can realize the two-way buffering function of the oil cylinder. During the working process of the oil cylinder, when the piston is close to the stroke end of one end of the oil cylinder, only the combination valve arranged at the end of the oil cylinder is activated to play the buffer function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com