Pneumatic ash discharging device for ash deposition at bottom of tail flue of pulverized coal fired boiler

A tail flue and pulverized coal boiler technology, which is applied in combustion methods, lighting and heating equipment, solid residue removal, etc., can solve problems affecting the health of operators, high ash accumulation temperature in the tail flue, and dust that is not environmentally friendly , to achieve the effect of being conducive to environmental protection and sanitation, avoiding dust on site, and avoiding personal injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

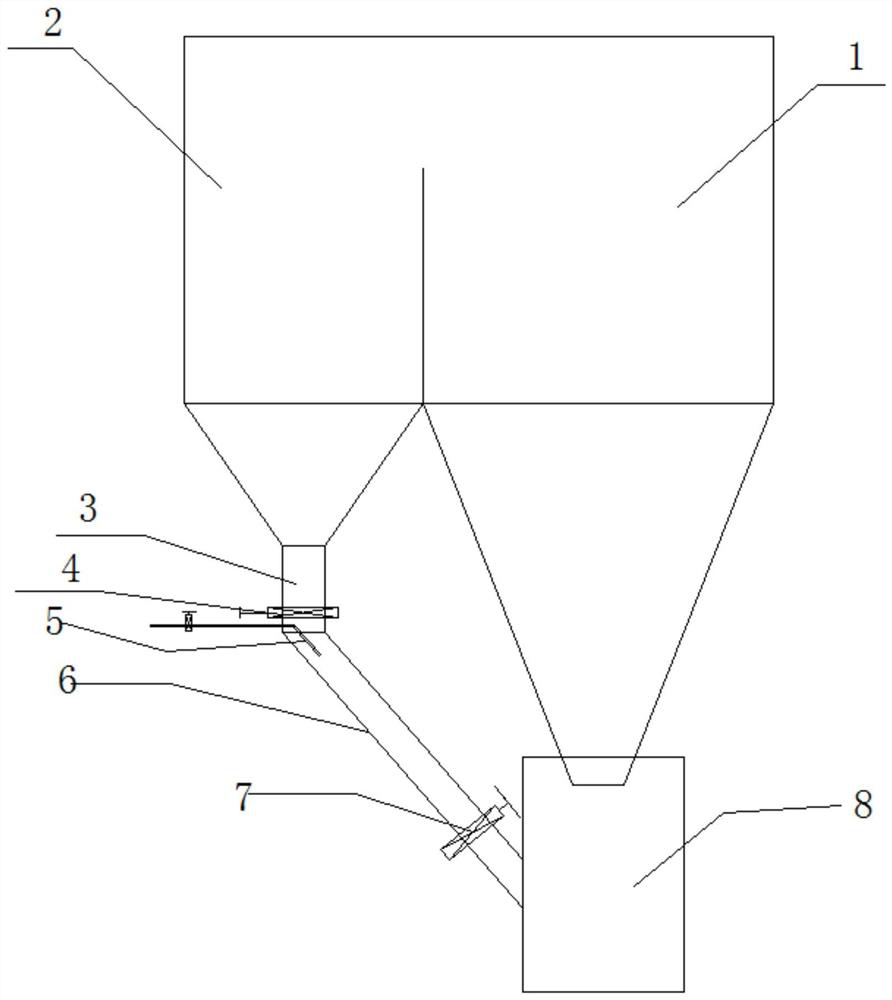

[0015] Referring to the accompanying drawings of the description, a pneumatic ash lowering device for dust accumulation at the bottom of the tail flue of a pulverized coal boiler described in this embodiment includes a boiler, and the boiler includes a furnace 1 and a tail flue 2 set up front and back. The tail flue 2 The bottom is connected with the lower ash pipe 3 of the tail flue, and the lower ash pipe 3 of the tail flue is connected with the ash conveying pipe 6, and the ash conveying pipe 6 is connected to the slag extractor 8, and the lower ash pipe 3 of the tail flue is connected with the ash conveying pipe 6. There is a purging device inside the pipe 6.

[0016] The lower ash pipe 3 of the tail flue is provided with a pneumatic flapper valve 4, and the side of the lower ash pipe 3 of the tail flue below the pneumatic flapper valve 4 is provided with a compressed air pipe 5, and the compressed air pipe 5 passes through the lower flue of the tail flue. The ash pipe 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com