Damage positioning imaging method and system based on non-linear Lamb wave zero frequency component

A zero-frequency component, damage localization technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measurement devices, etc. Problems such as detection and complex operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

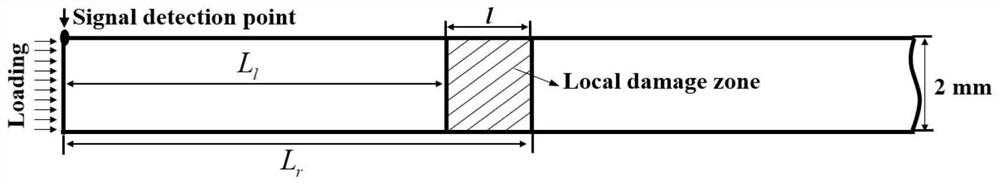

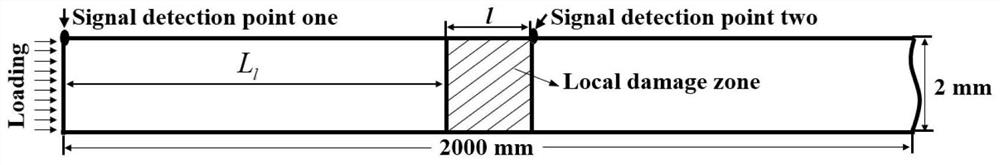

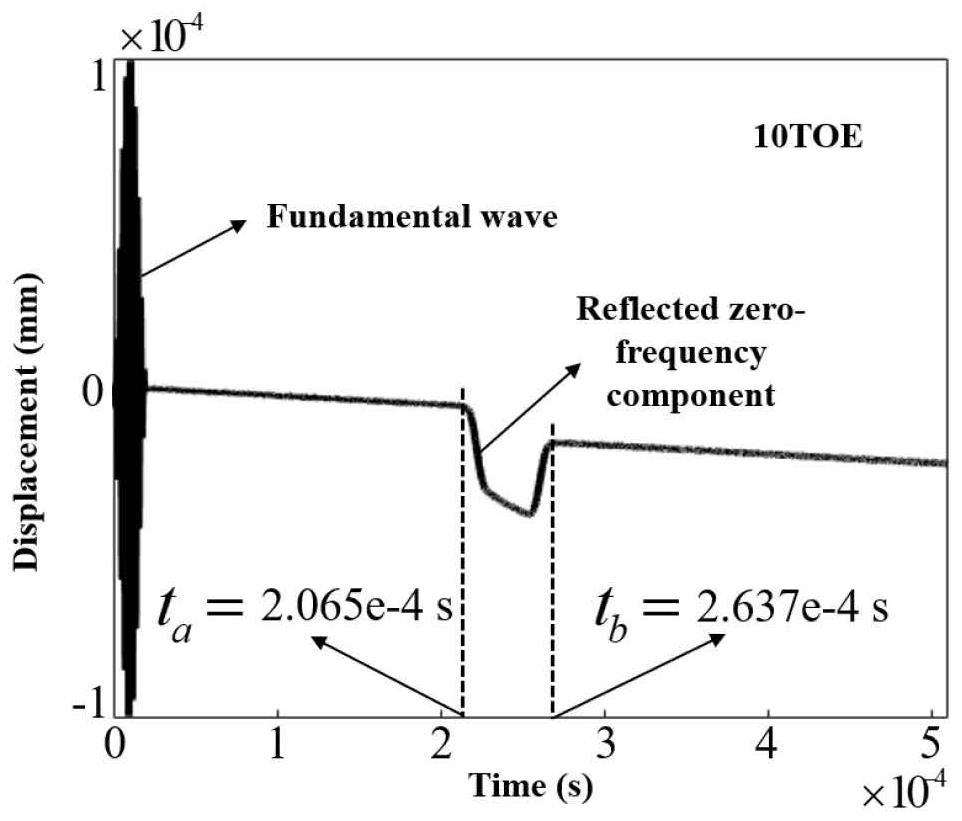

[0034] Such as figure 1 Shown, L l The distance from the left boundary of the local damage to the signal excitation point, v is the fundamental wave phase velocity, v 0 is the zero-frequency phase velocity, t a is the arrival time of the zero-frequency signal received by the signal receiving point (also the signal transmitting point), there is

[0035]

[0036] L r is the distance from the right boundary of the local damage to the signal excitation, t l is the departure and end time of the zero-frequency signal received by the signal receiving point (also the signal transmitting point), Δt is the width of the zero-frequency signal generated in the local damage area, and

[0037]

[0038] The width of the local damage area is

[0039] l=L r -L l (3)

[0040] According to the inventors in the document "SUN X Q, LIU H J, ZHAO Y X, et al. The zero-frequency component of bulk waves in solids with randomly distributed micro-cracks [J]. Ultrasonics, 2020, 107: 106172."...

Embodiment 2

[0056] The difference between this embodiment and Embodiment 1 is that the ultrasonic probe in this embodiment (mainly referring to the receiving point) includes: a housing 1, a CMUT sheet 4, an acoustic lens 3 and a controller; the CMUT sheet 4 includes multiple a CMUT element; the acoustic lens 3 is located on the surface of the CMUT sheet 4; the bottom surface of the CMUT sheet 4 is provided with a liner layer 7, the liner layer 7 is bonded to the CMUT sheet 4, and the liner layer 7 and the acoustic lens 3 are respectively Located at the top and bottom of the CMUT sheet 4; the CMUT sheet 4 is connected to the flexible substrate 2 through a wire; the flexible substrate 2 is electrically connected to the controller (the flexible substrate 2 is also connected to the controller with an external power lamp and other equipment); the housing 1 is provided with a piezoelectric ceramic sheet 5, and the piezoelectric ceramic sheet 5 is provided with an electrode 6 with opposite polari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com