Double-break isolating switch

A technology of isolating switch and double-break, applied in the field of GIS power station, can solve the problem of large influence of insulation structure, and achieve the effect of being conducive to compact design, ensuring stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

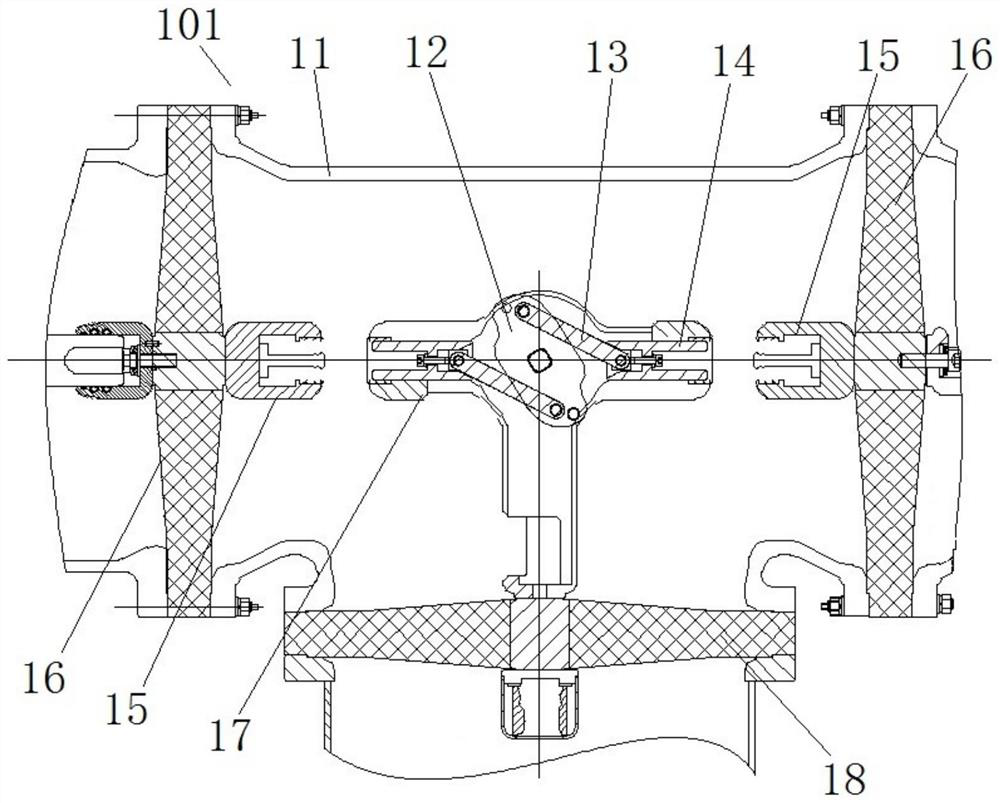

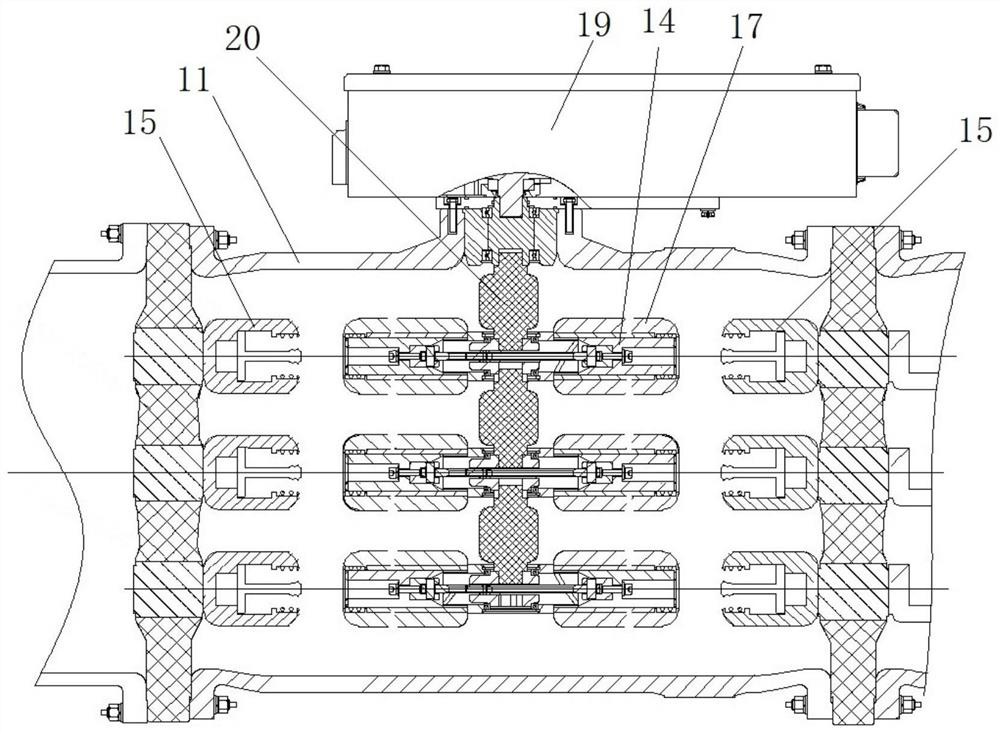

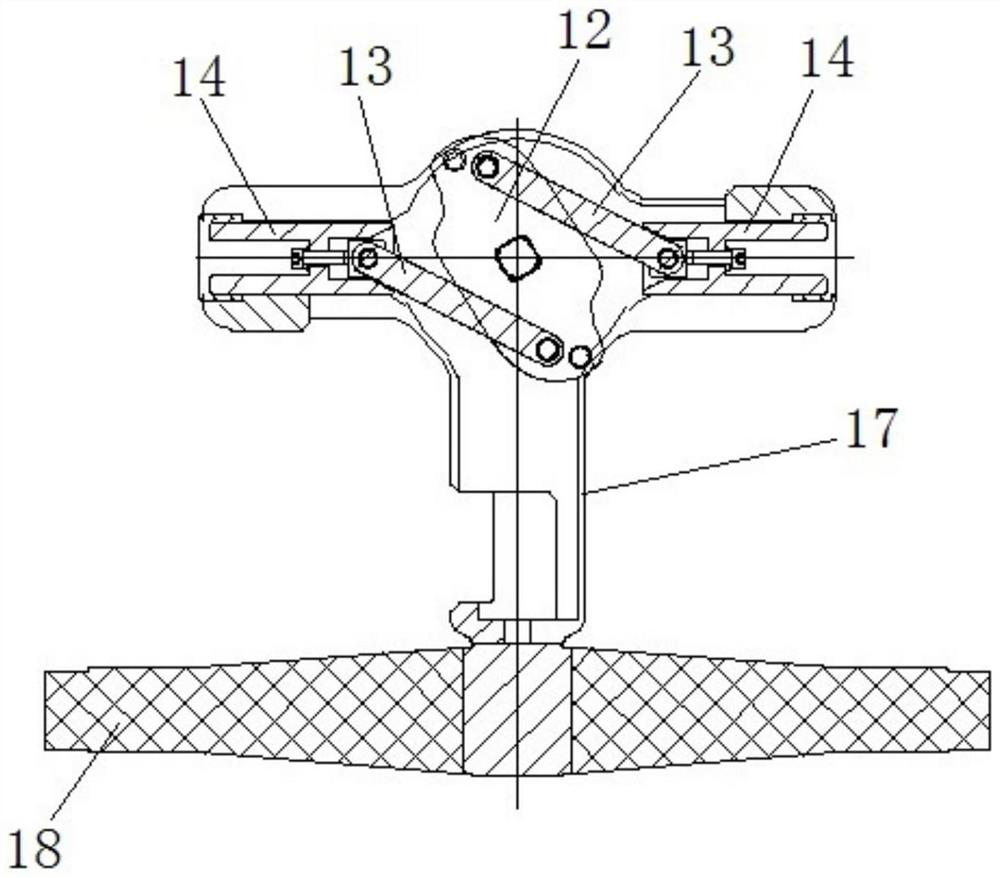

[0043] like figure 1 and figure 2 As shown, the double-break isolating switch 101 includes a cylinder body 11, with the axial direction of the cylinder body 11 as the left and right directions, the left and right ends of the cylinder body 11 are respectively provided with end insulators 16, and the inner sides of the two end insulators 16 are respectively fixed. There are static contacts 15 , two static contacts 15 are coaxially arranged, and the static contacts 15 are in the middle of the corresponding end insulators 16 . Wherein, the double-break isolating switch 101 is a three-phase common box structure. In other embodiments, the double-break isolating switch may be a single-phase box-divided structure.

[0044] In this embodiment, a side insulator 18 is provided on the lower part of the cylinder body 11, and a movable contact seat 17 is fixed on the inner side of the side insulator 18. The movable contact seat 17 has a circular cavity and two guide holes, and the two gu...

Embodiment 2

[0059] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the rotating member is a rotating crank arm. In this embodiment, the rotating member is a rotating disk. In other embodiments, in order to avoid interference between the rotating disk and the movable contact, avoidance gaps may be provided at corresponding positions of the rotating disk.

Embodiment 3

[0061] The difference between this embodiment and embodiment 1 lies in that in embodiment 1, an avoidance notch for avoiding the corresponding moving contact is provided on the rotating crank arm. In this embodiment, when the moving stroke of the movable contact is relatively small, no escape gap may be provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com