Plug and plug assembly

A technology of plugs and plug shells, which is applied in the direction of electrical components, parts of connecting devices, fixed/insulated contact components, etc., can solve the problems of signal shielding effect and poor shielding continuity, and achieve the effect of improving the shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

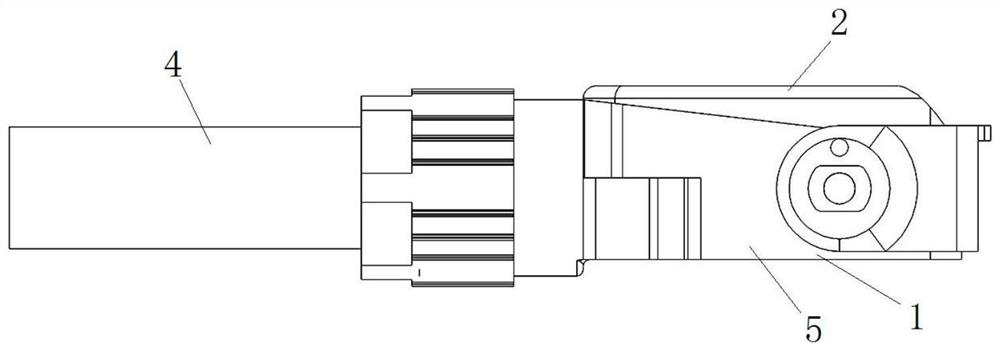

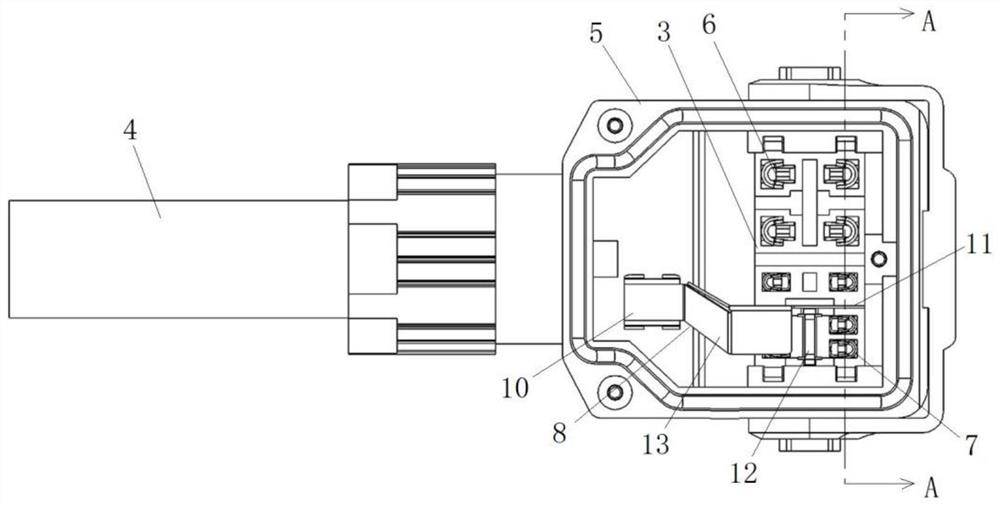

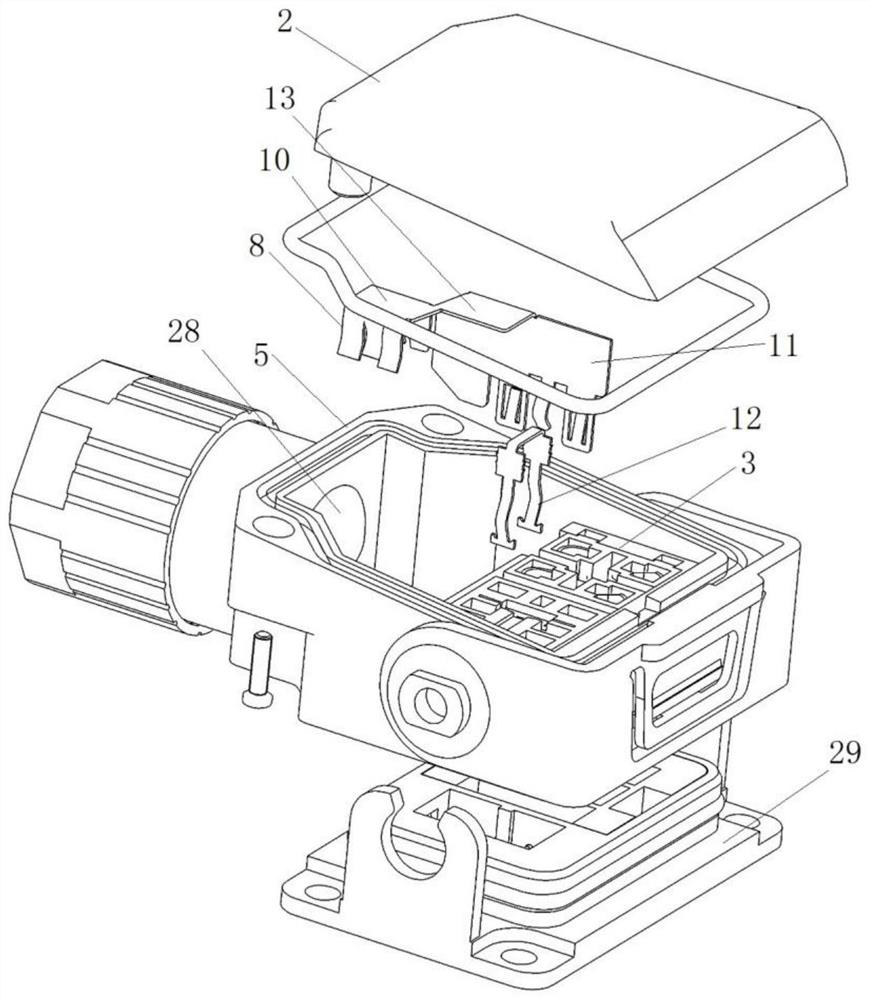

[0079] Such as figure 1 and figure 2 As shown, the plug assembly includes a plug and a cable 4, the plug includes a plug housing 1, the plug housing 1 has an inlet channel for the cable 4 to extend into the plug housing 1, and the cable 4 includes a signal harness and a power harness. Such as figure 2 , image 3 and Figure 6 As shown, the plug housing 1 includes a bottom case 5 and an upper cover 2 detachably fixed on the bottom case 5 by screws, as figure 1 and Figure 7 As shown, the upper cover 2 and the bottom case 5 are arranged in the up-down direction, and the plug also includes an insulator 3. After the upper cover 2 is opened, the insulator 3 exposes the bottom case 5, and the bottom case 5 has an insulator installation hole extending in the up-down direction. The insulator 3 is plugged and fitted with the bottom shell 5 from top to bottom, and the lower end of the insulator 3 forms a plug-in end for plugging into the socket. The upper stop plane, the stop pl...

specific Embodiment 2

[0093] The difference from the specific embodiment 1 is that the isolating part and the inserting part are integrated, no slot is provided on the insulator, the cantilever arm on the isolating part is fitted with the T-shaped slot, and the cantilever arm includes a The overhanging section also includes a vertical section located at the overhanging end of the overhanging section and perpendicular to the insertion direction. The vertical section guides and cooperates with the groove wall of the T-shaped slot so that the vertical section forms a guide. The part arched out of the notch of the socket forms the contact part of the socket, which is electrically connected with the socket housing when the plug and the socket are mated.

specific Embodiment 3

[0095] The difference from the specific embodiment 1 is that no slot is provided on the insulator, no cantilever arm is provided on the isolation part, and the main body of the isolation part is provided with a pin extending toward the signal contact installation area at the middle position of the two isolation cantilever arms. part, which is press-fitted with the bottom wall of the U-shaped structure of the insertion part in the insertion direction after the isolation part is positioned and installed, so as to realize the conductive communication between the isolation part and the insertion part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com