Product fault prediction method and system based on X-ray image reinspection

A detection system, X-ray technology, applied in image enhancement, image analysis, radiation intensity measurement, etc., can solve problems such as high cost for manufacturers and product failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

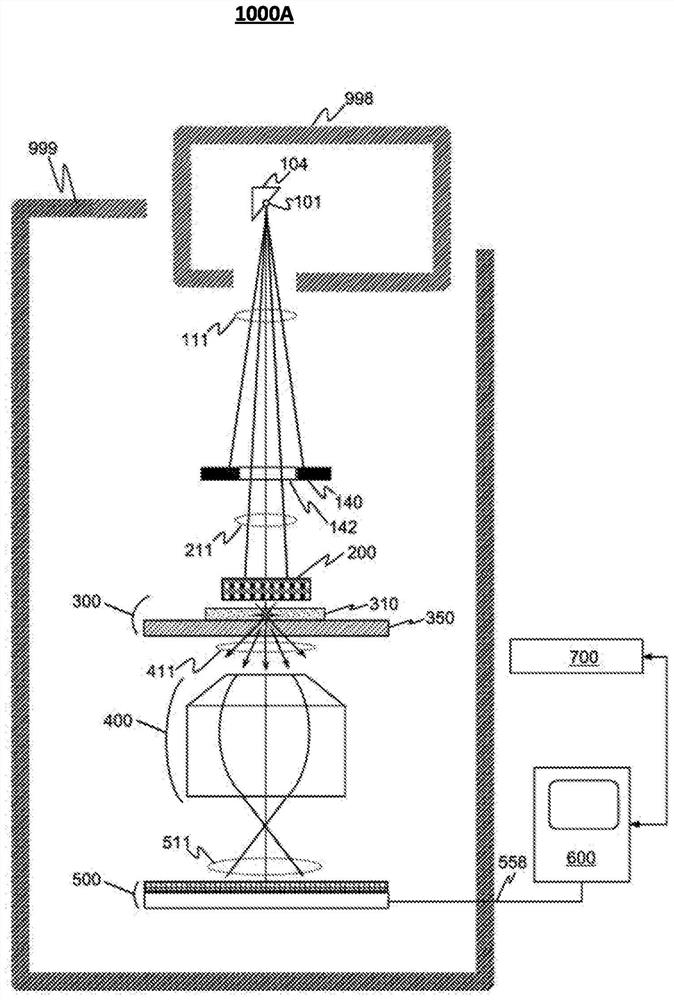

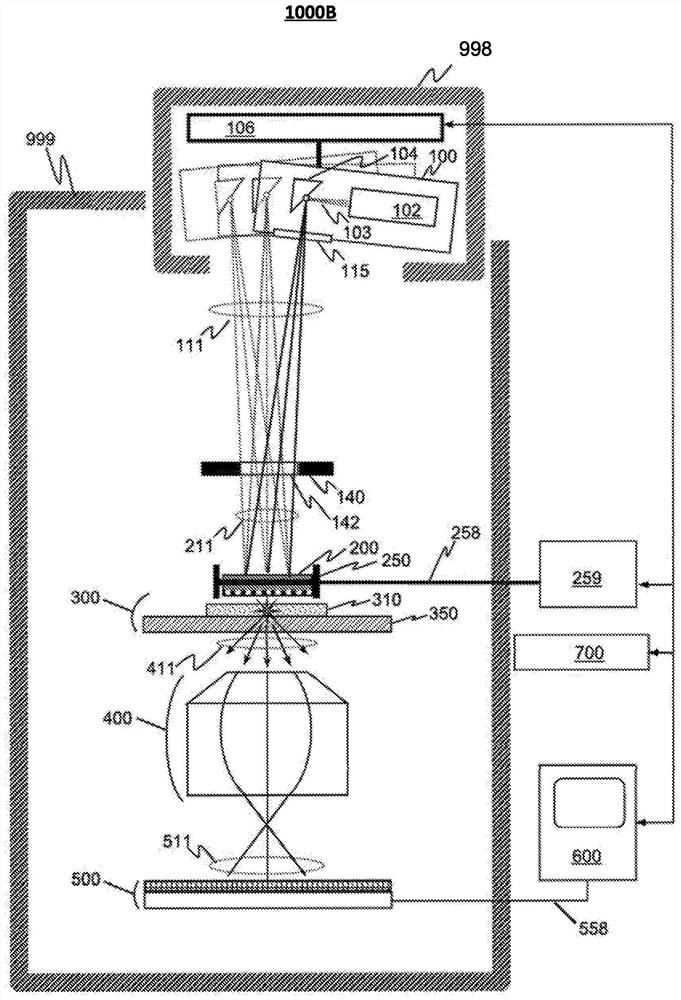

[0015] Automatic high-speed X-ray inspection system

[0016] X-ray system frame

[0017] The systems and methods disclosed herein relate to a system or use of a system that illuminates an object to be inspected or inspected with X-rays that convert the X-rays into visible (or near-visible) photons, forming visible (or near-visible) photons images, and then convert the images into electronic form. Accordingly, various embodiments of the X-ray imaging system will be described first, followed by various embodiments of methods and systems utilizing the X-ray imaging system.

[0018] Although a wide variety of objects may be inspected or inspected using the apparatus disclosed herein, it is contemplated that it is particularly applicable to the inspection and inspection of integrated circuit wafer and package assemblies. One example of this is a silicon interposer, including silicon with multiple TSVs, but the invention can also be used to inspect integrated circuits (ICs) th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com