Electric nasal cavity cleaner

A cleaner and nasal cavity technology, applied in the field of nasal cavity cleaning appliances, can solve problems such as inconvenience in use, inconvenience in use, choking the nose, etc., and achieve the effects of avoiding damage, facilitating replacement, and increasing comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

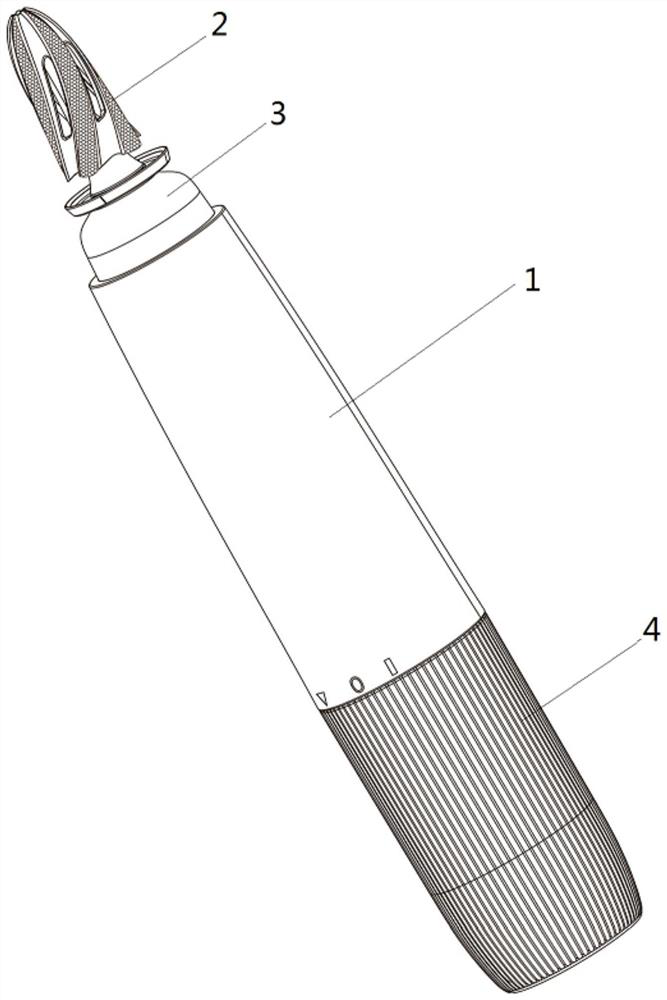

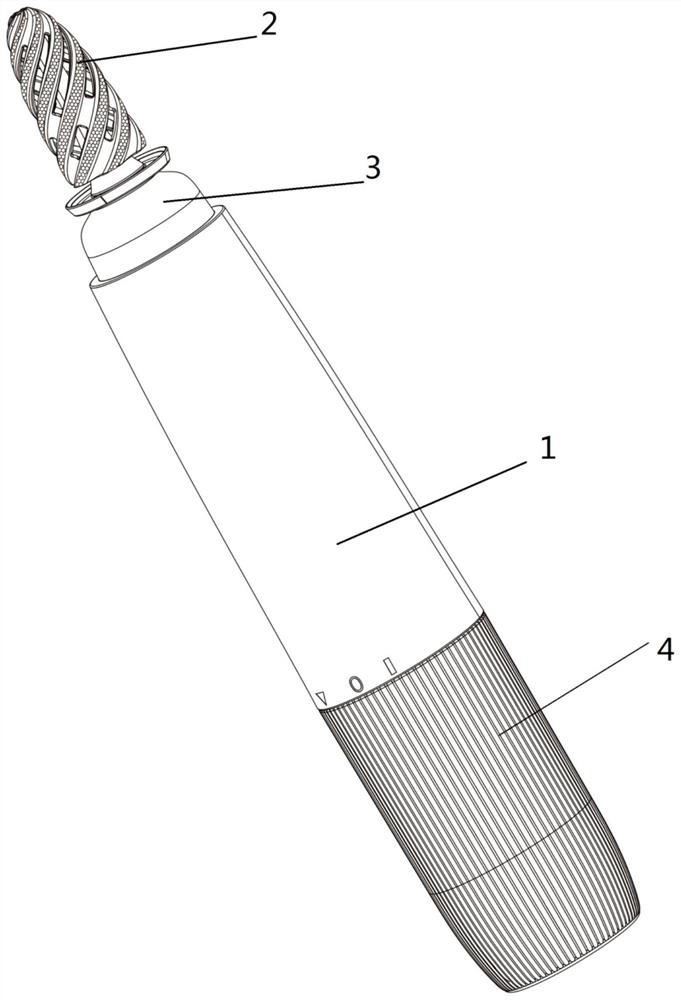

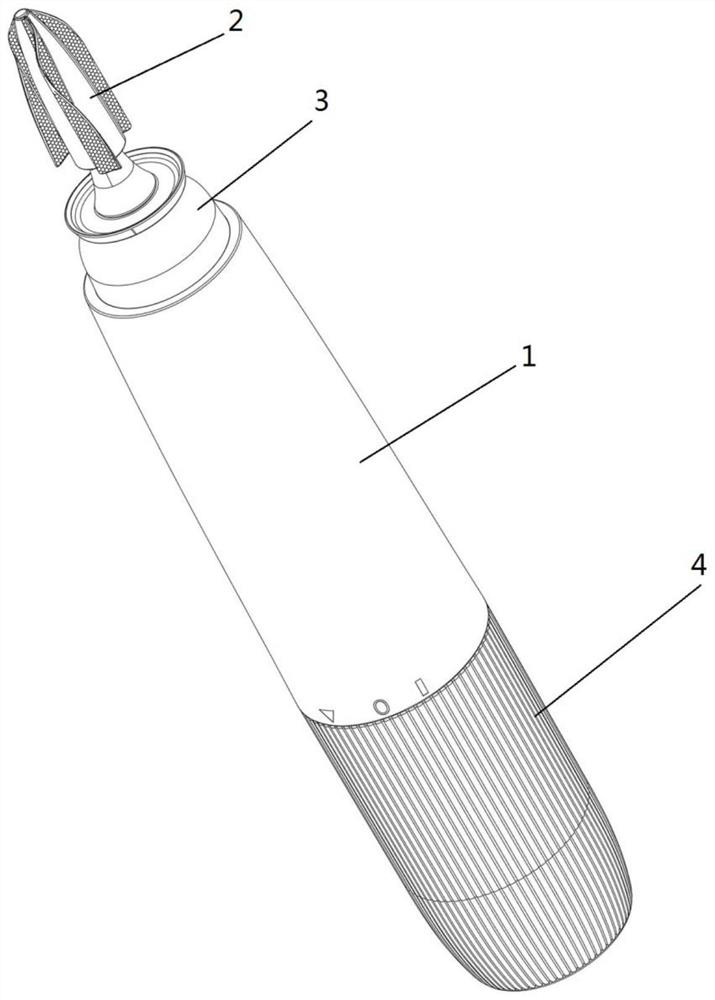

[0046] Such as figure 1 with figure 2 As shown, the electric nasal cavity cleaner includes a brush handle, and the brush handle includes a handle body 1, a top cover 3 that is clamped and fixed on the handle body 1 and can be rotated at a certain angle relative to the handle body 1 to realize the electric Base 4 for the nasal cleaner switch, such as Figure 7 with Figure 12 As shown, the power structure 5 is installed in the space formed by the handle body 1 and the base 4, and the inner wall above the handle body 1 relative to the power structure 5 is provided with a baffle plate 15 capable of fixing the power structure 5, The position of the baffle plate 15 relative to the output shaft is provided with a mounting hole 12 through which the output shaft can be inserted into the top cover 3, and a waterproof ring is provided between the mounting hole 12 and the output shaft 7. It can prevent water from entering the handle body 1, so that the nasal cavity cleaner can be was...

Embodiment 2

[0070] According to the nasal cavity cleaner described in Embodiment 1, another implementation of the cleaning part 23 is provided, such as image 3 and Image 6 As shown, the outer peripheral wall of the cleaning part 23 is provided with a plurality of second convex parts 29, and the second convex parts 29 are arranged at intervals along the longitudinal direction of the cleaning part 23. In this embodiment, the second convex parts There are three protrusions 29, and in other embodiments, other numbers, such as two, four, six, etc., can be set according to actual conditions and needs.

[0071] The surface of the second convex portion 29 is distributed with the plurality of water absorption groove points 26 .

[0072] The second protruding part 29 is a bent sheet structure, including a first protruding piece 291 arranged on the outer peripheral wall of the cleaning part 23, and a second protruding piece connected to the lower part of the first protruding piece 291 by bending....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com