Cleaning device for dialysis equipment

A cleaning device and equipment technology, applied in the field of hemodialysis machines, can solve problems such as cross-infection, low efficiency, and unclean wiping, and achieve the effect of convenient centralized processing and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

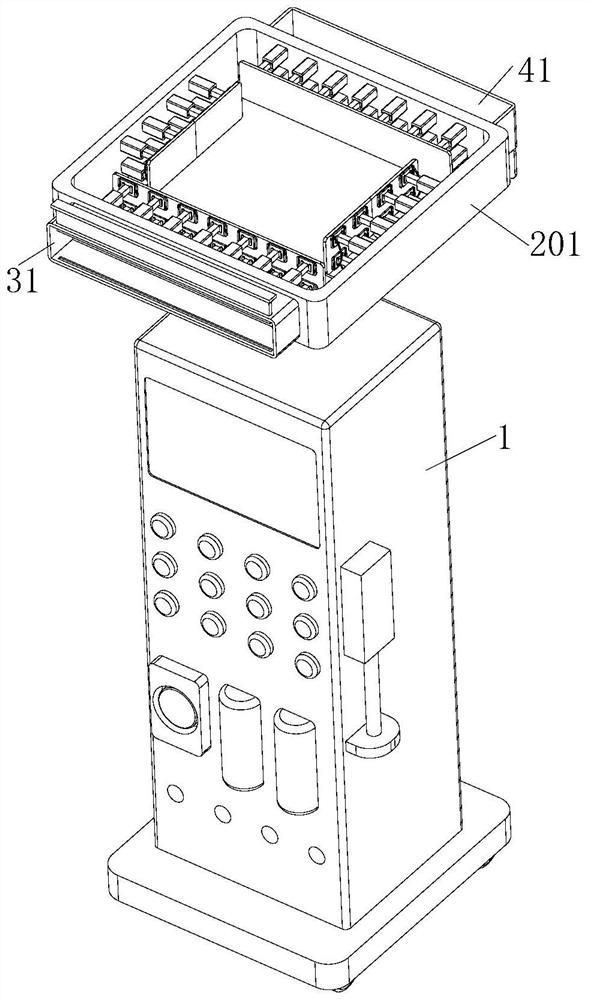

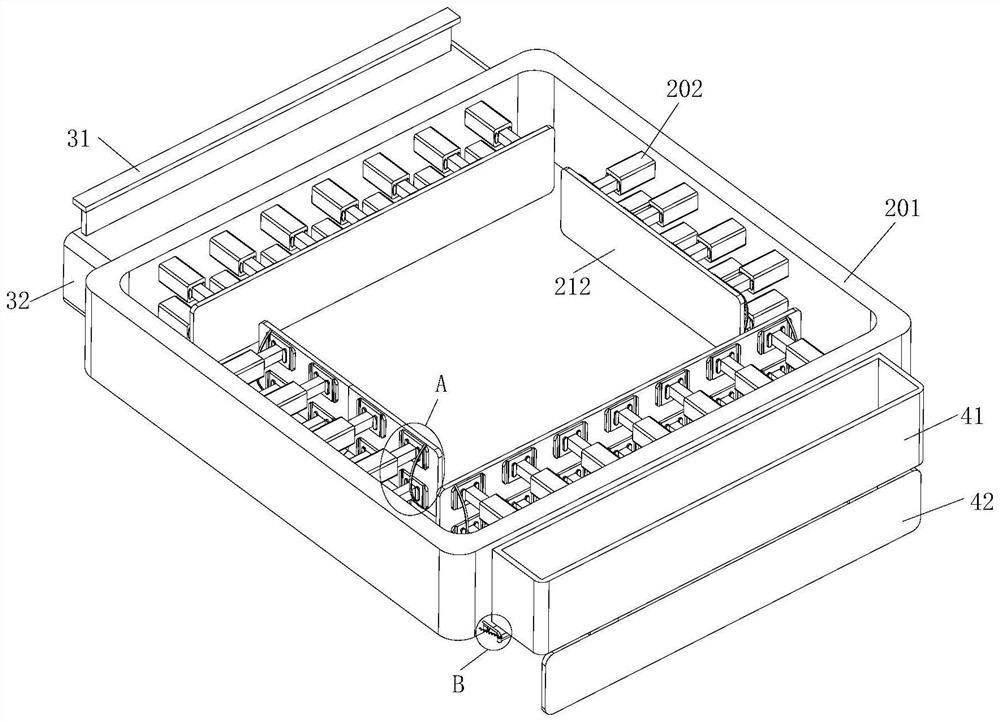

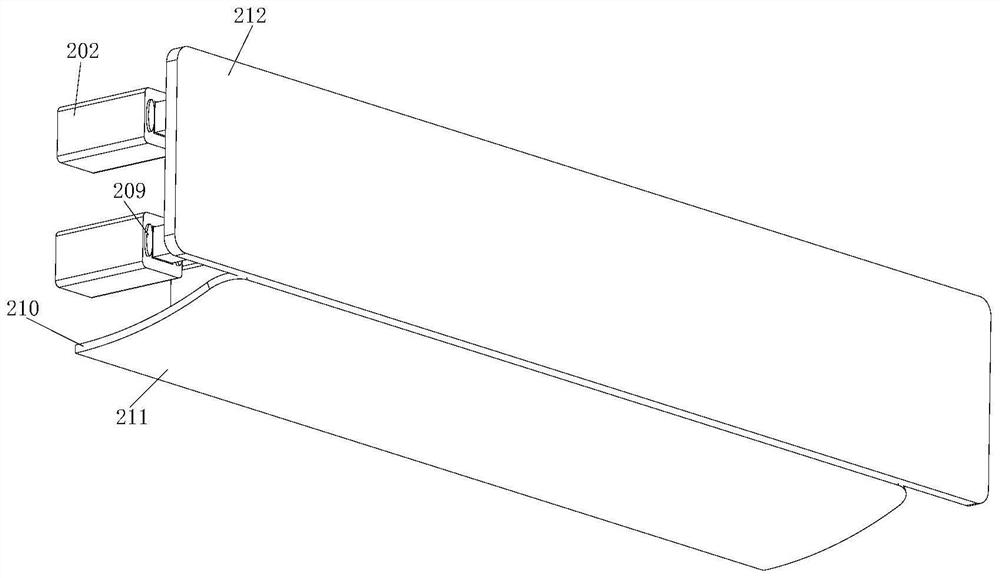

[0029] see Figure 1-6 As shown, a dialysis equipment cleaning device includes a hemodialysis machine 1, a cleaning frame 201 and a connecting column 202; the top of the hemodialysis machine 1 is provided with a cleaning frame 201, and the inner wall of the cleaning frame 201 is fixedly equipped with a connecting column 202, the inside of the connecting column 202 is slidably connected with a sliding column 203, the inside of the connecting column 202 is fixedly installed with a first spring 204, the other end of the first spring 204 is fixedly installed with the sliding column 203, and the sliding One end of the column 203 away from the first spring 204 is fixedly equipped with a rectangular plate 205, and the side of the rectangular plate 205 away from the sliding column 203 is provided with a sterile cotton cloth 212; At this time, put the cleaning frame 201 on the upper end of the hemodialysis machine 1, and then slide the cleaning frame 201 down the hemodialysis machine 1...

Embodiment 2

[0038] see Figure 7 As shown in Comparative Example 1, as another embodiment of the present invention, handles 5 are fixedly installed on both sides of the cleaning frame 201, and the inner wall of the handle 5 is provided with four grooves 6; when working, when When the cleaning frame 201 needs to be moved, by gripping the handle 5, the four grooves 6 on the inner wall of the handle 5 just fit the fingers, so that it is convenient to grip the handle 5, and then the handle 5 is moved with the cleaning frame 201.

[0039] Working principle, by pulling the elastic bandage 206 on the sterile cotton cloth 212, the space between the elastic bandage 206 and the sterile cotton cloth 212 becomes larger, and the sterile cotton cloth 212 is placed on the rectangular plate 205, so that the elastic bandage 206 is inserted into the In the slot 207, the sterile cotton cloth 212 and the fast rectangular plate 205 are then fixed. At this time, the cleaning frame 201 is placed on the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com