High-precision laser minimally invasive functional film and manufacturing method thereof

A high-precision, laser technology, applied in the field of tobacco, can solve the problems of difficult quality control, low production efficiency, high cost, etc., and achieve the effect of guaranteeing the design concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

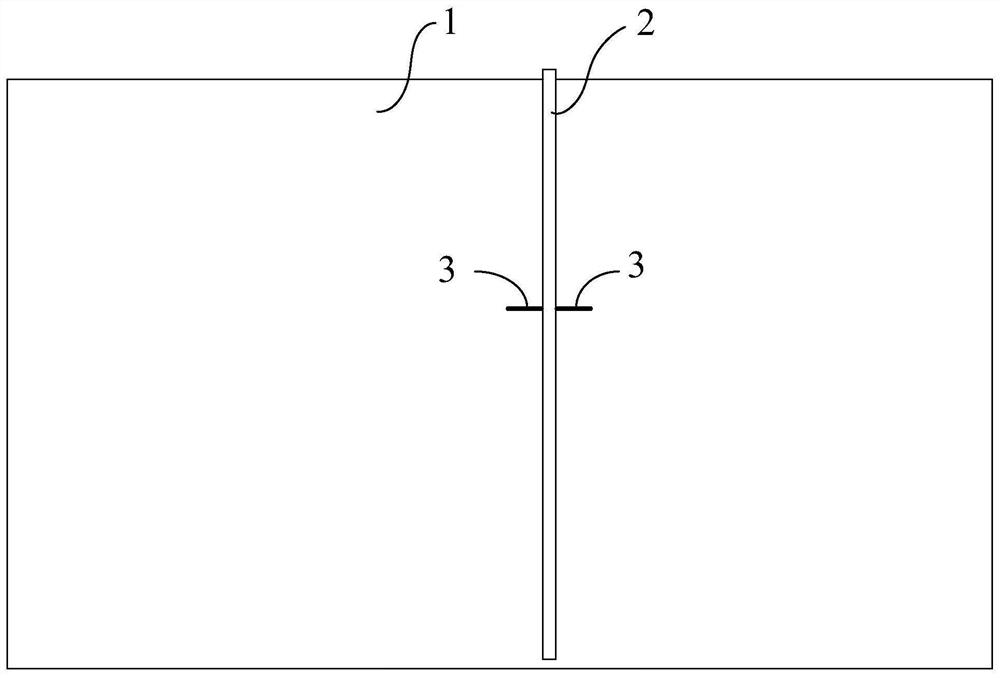

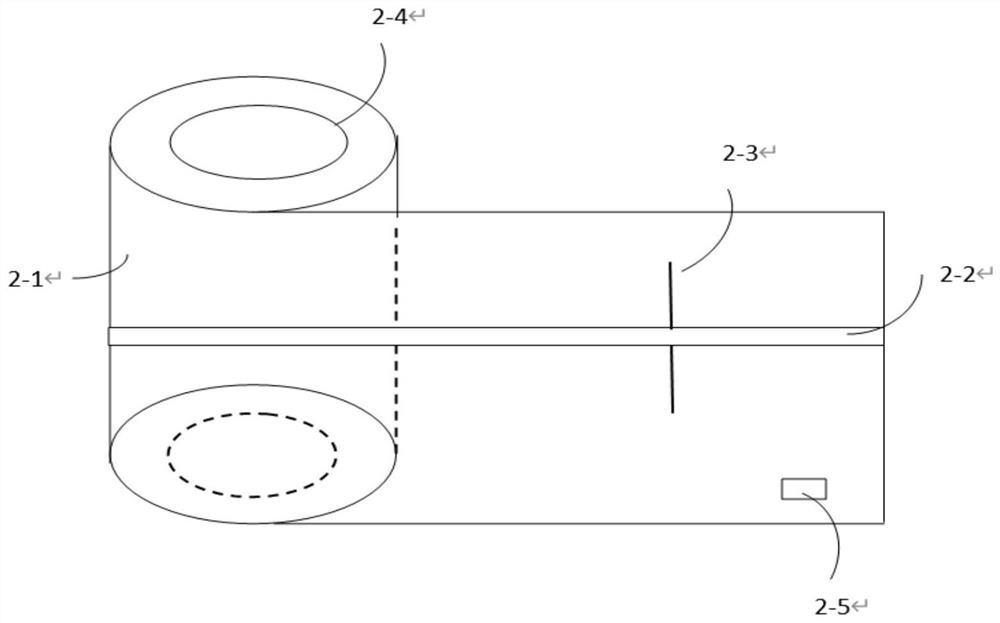

[0081] The film used in the high-precision laser minimally invasive functional film in this embodiment is BOPP, which is divided into three layers of upper layer, middle layer and lower layer, with a total thickness of 18 μm, a laser frequency of 20%, a tangent depth of 8 μm, and a tangent length of 10 mm (10mm on both sides of the gold wire);

[0082] The manufacturing method of the above-mentioned high-precision laser minimally invasive BOPP cigarette film is as follows:

[0083] (1) Film roll unwinding

[0084] Place the BOPP cigarette film cut according to the required width on the unwinding position of the equipment;

[0085] (2) Surface treatment

[0086] Corona treatment is carried out on the coding area of the film. If the surface tension of the film itself is greater than 37 dynes and the adhesion to the ink is sufficient, it may be considered not to use corona treatment;

[0087] (3) Gold pull wire

[0088] Press the gold wire on the designated position of the ...

Embodiment 2

[0098] The film used in the high-precision laser minimally invasive functional film in this embodiment is BOPP, which is divided into three layers: upper layer, middle layer and lower layer. (15mm on both sides of the gold wire);

[0099] The manufacturing method of the above-mentioned high-precision laser minimally invasive BOPP cigarette film is as follows:

[0100] (1) Film roll unwinding

[0101] Place the BOPP cigarette film cut according to the required width on the unwinding position of the equipment;

[0102] (2) Surface treatment

[0103] Corona treatment is carried out on the coding area of the film. If the surface tension of the film itself is greater than 37 dynes and the adhesion to the ink is sufficient, it may be considered not to use corona treatment;

[0104] (3) Gold pull wire

[0105] Press the gold wire on the designated position of the film, this step is better implemented on the customer's cigarette charter machine;

[0106] (4) Online coding

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com