Coal gangue all-aggregate concrete and preparation method thereof

A technology of coal gangue and full aggregate, applied in the field of coal gangue full aggregate concrete and its preparation, can solve the problems of land resource occupation, complicated process, low efficiency, etc., and achieve the effects of improving production efficiency, improving macroscopic mechanical properties, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

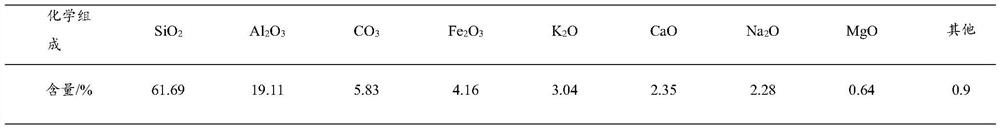

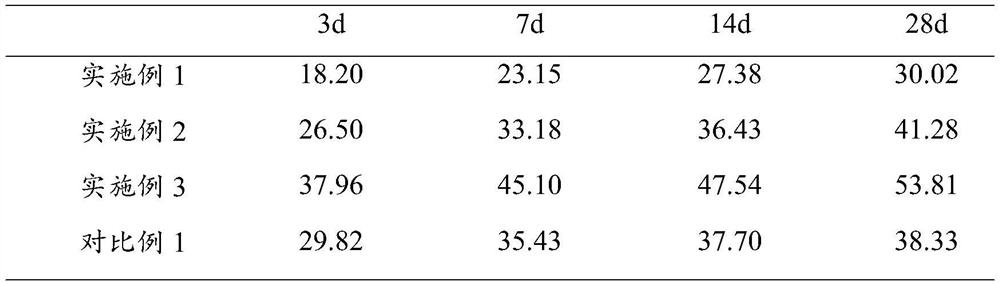

[0035] The preparation method of coal gangue full aggregate concrete comprises the following steps:

[0036] In the first step, the raw materials of coal gangue full aggregate concrete include the following proportions by mass: Portland cement, coal gangue fine aggregate, coal gangue coarse aggregate, external water reducing agent, and water are 271 parts and 691 parts respectively. , 1228 copies, 1.4 copies and 190 copies;

[0037] Step 2: Add coal gangue coarse aggregate, coal gangue fine aggregate, and Portland cement into the mixer in turn, mix and stir well, and fully stir for 2 minutes; after mixing evenly, slowly add the mixed water reducer and water, Fully stir for 3 minutes;

[0038] Step 3: After testing, the 28d compressive strength of coal gangue full aggregate concrete reaches 30.02MPa.

Embodiment 2

[0040] The preparation method of coal gangue full aggregate concrete comprises the following steps:

[0041] In the first step, the raw materials of coal gangue full aggregate concrete include the following proportions by mass: Portland cement, coal gangue fine aggregate, coal gangue coarse aggregate, water reducing agent, and water are 345 parts and 664 parts respectively. 1180, 1.7 and 190;

[0042] Step 2: Add coal gangue coarse aggregate, coal gangue fine aggregate, and Portland cement into the mixer in turn, mix and stir well, and fully stir for 2 minutes; after mixing evenly, slowly add the mixed water reducer and water, Stir fully for 3 minutes; the third step: After testing, the 28d compressive strength of coal gangue full aggregate concrete reaches 41.28MPa.

Embodiment 3

[0044] The preparation method of coal gangue full aggregate concrete comprises the following steps:

[0045] In the first step, the raw materials of coal gangue full aggregate concrete include the following proportions by mass: Portland cement, coal gangue fine aggregate, coal gangue coarse aggregate, water reducing agent, and water are 475 parts and 617 parts respectively. 1098, 2.4 and 190;

[0046] Step 2: Add coal gangue coarse aggregate, coal gangue fine aggregate, and Portland cement into the mixer in turn, mix and stir well, and fully stir for 2 minutes; after mixing evenly, slowly add the mixed water reducer and water, Fully stir for 3 minutes;

[0047] Step 3: After testing, the 28d compressive strength of coal gangue full aggregate concrete reaches 53.81MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com