High-pressure environment marine microorganism solid separation culture device and culture method

A technology for separation and culture of marine microorganisms, which is applied in the field of solid separation and cultivation devices for marine microorganisms in a high-pressure environment, can solve the problems of separation and cultivation of marine microorganisms, and cannot effectively improve the success rate of cultivation, and achieves the effect of improving cultivability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

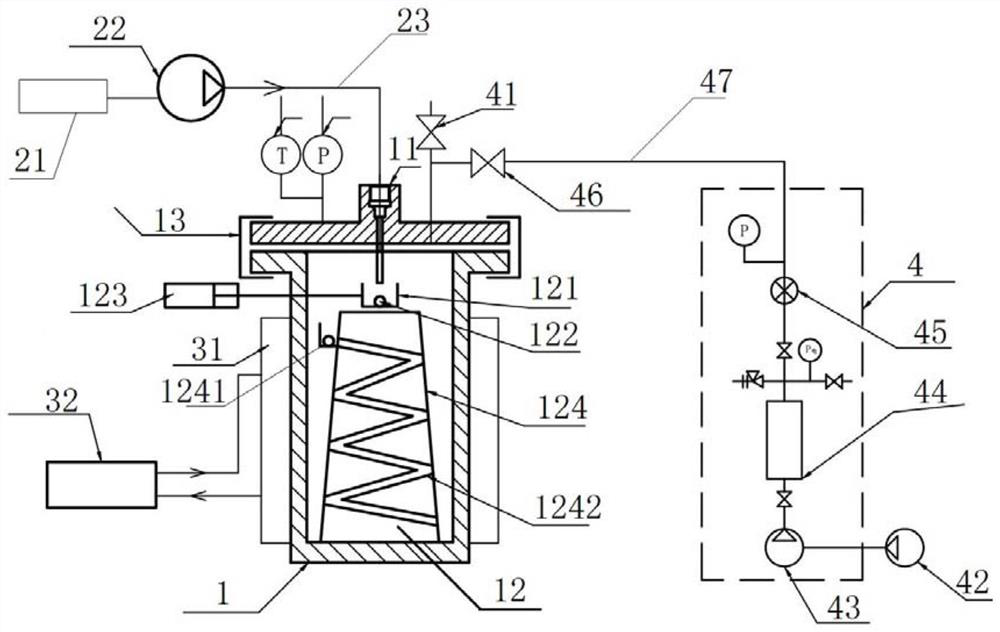

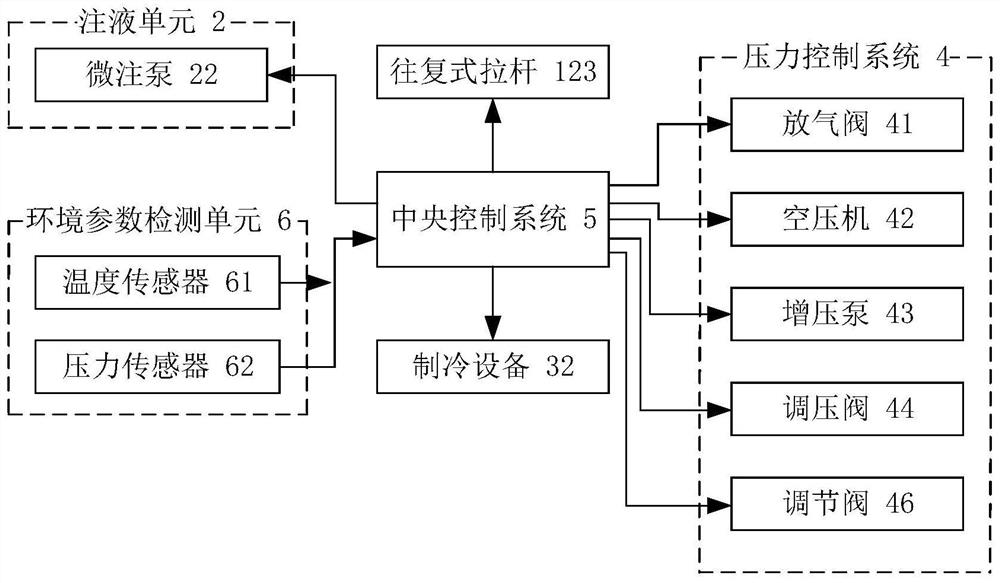

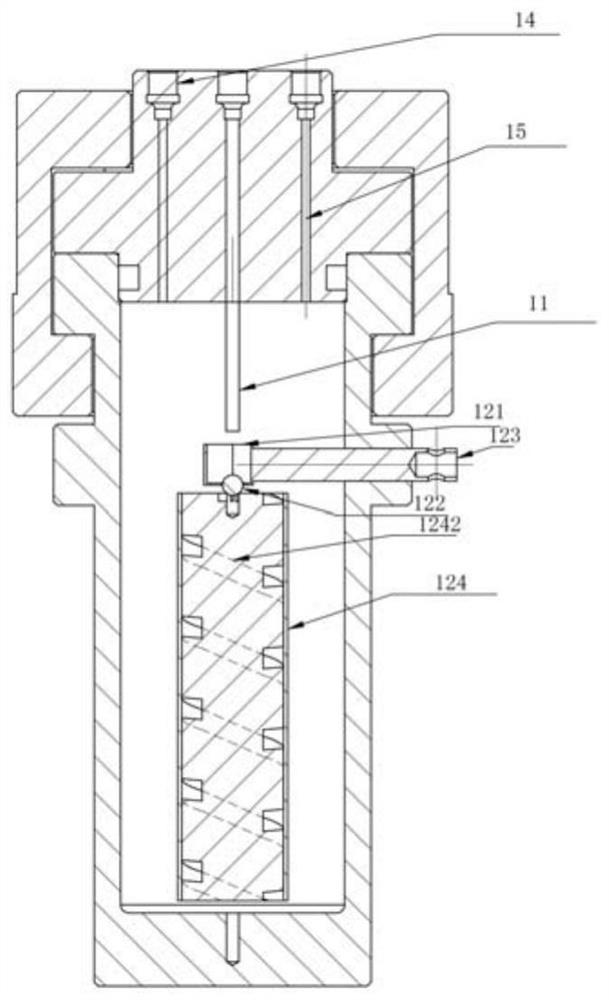

[0059] Such as figure 1 , figure 2 As shown, a high-pressure environment marine microorganism solid separation and cultivation device includes a high-pressure microorganism separation and cultivation chamber 1, a liquid injection unit 2, a temperature control system 3, a pressure control system 4, an environmental parameter detection unit 6 and a central control system 5; The high-pressure microorganism separation and cultivation chamber 1 is provided with a microorganism separation branch 12, which is used to separate the microorganisms and provide an area for microorganism cultivation to the greatest extent; The microorganism separation and cultivation chamber 1 is connected to the liquid injection unit 2 through the central liquid injection pipe 11; the deep-sea microorganism enrichment liquid is injected into the microorganism separation branch 12 of the high-pressure microorganism separation and cultivation chamber 1 from the liquid injection unit 2; the temperature cont...

Embodiment 2

[0076] More specifically, such as Figure 5 As shown, the high-pressure microorganism separation and cultivation chamber 1 is provided with several sequentially, and the liquid injection unit 2 is connected with the central liquid injection pipe 11 of all high-pressure microorganism separation and cultivation chambers 1; the temperature control system 3 and the pressure control system 4 It is connected to all high-pressure microorganism isolation and cultivation chambers 1 respectively, and is used to construct a high-pressure and low-temperature environment consistent with the marine environment in each high-pressure microorganism isolation and cultivation chamber 1, so as to ensure that the enriched deep-sea microorganisms are isolated and cultivated under in-situ environmental conditions Each high-pressure microorganism separation and cultivation chamber 1 is connected with an independent environmental parameter detection unit 6 for real-time detection of changes in temperat...

Embodiment 3

[0079] More specifically, on the basis of Example 1, this embodiment also proposes a method for solid separation and cultivation of marine microorganisms in a high-pressure environment, which is realized by applying a device for separation and cultivation of marine microorganisms in a high-pressure environment as claimed in the claim, such as Figure 6 shown, including the following steps:

[0080] S1: Sterilize all components of the marine microbial solid separation and cultivation device in a high-pressure environment to maintain a sterile state;

[0081] S2: Install the medium required for culture after filling the microorganism separation branch 12, and detect the tightness of the marine microorganism solid separation and culture device in a high-pressure environment;

[0082] S3: Turn on the temperature control system 3 to ensure that the temperature in the high-pressure microorganism separation and cultivation chamber 1 is consistent with the temperature conditions of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com