Abrasion test bench

An abrasion test and abrasion technology, applied in the direction of testing wear resistance, testing machinability, instruments, etc., can solve problems such as wear failure, and achieve the effect of reducing wear loss, reducing random error of test, and occupying less land.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

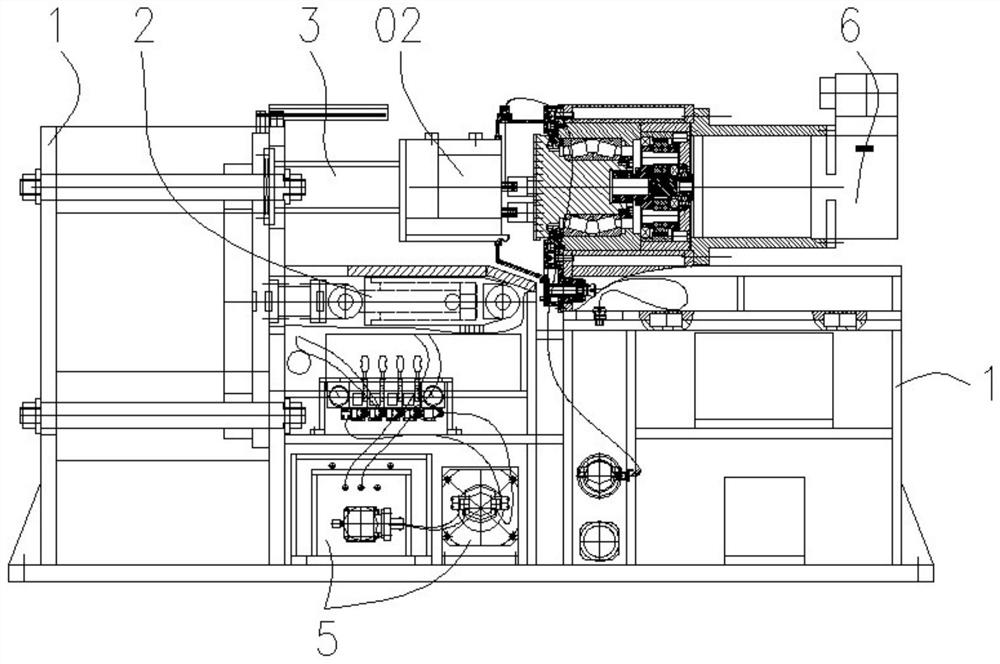

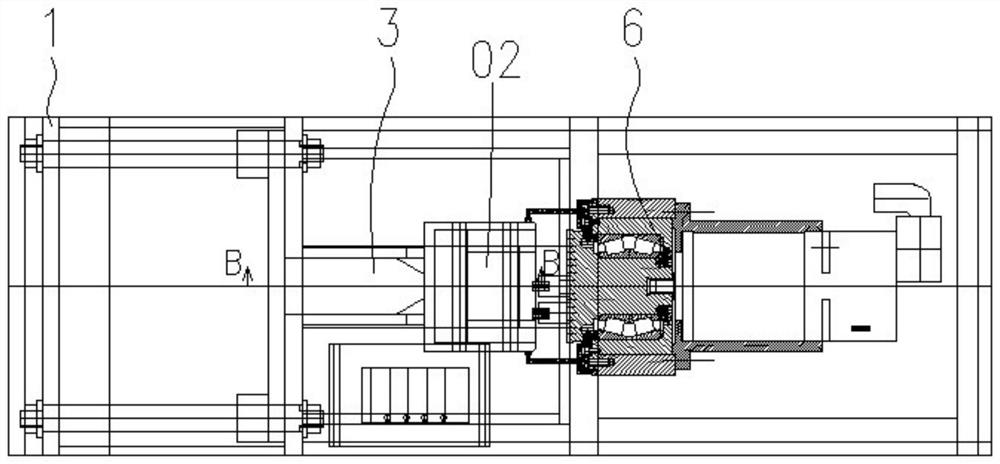

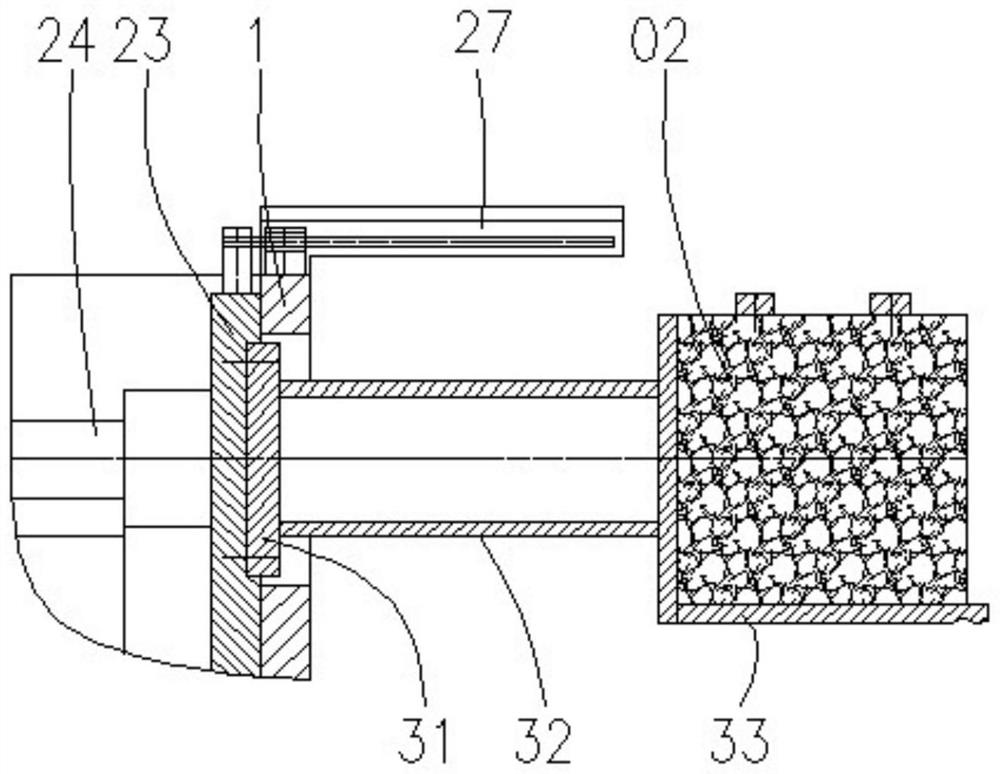

[0028] Such as Figure 1-6 As shown, the present invention discloses an abrasion test bench, comprising a frame 1, a linear reciprocating mechanism 2, a guide seat 23, a guide rod 24, an abrasive rock sample seat 33, an abrasive rod 67, an abrasive rotary power system 6 and a force sensor 25 . The frame is the installation base structure for other components on the abrasion test bench. The front and rear ends of the guide rod are installed on the frame, and the guide seat is sleeved on the guide rod and is slidingly connected with the guide rod back and forth. Both the linear reciprocating mechanism and the abrasive rotary power system are installed on the frame and arranged at intervals up and down. The movable end of the linear reciprocating movement mechanism and the abrasive rock sample seat are connected with the guide seat and are located at the rear side of the guide seat. When the movable end of the linear reciprocating mechanism moves back and forth, the guide seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com