High-speed low-power-consumption capacitive touch detection circuit, method and chip

A technology of capacitive touch and detection circuit, applied in capacitance measurement, measurement of resistance/reactance/impedance, electronic switches, etc., can solve the problems of increasing chip cost and power consumption, small touch difference, and high chip power consumption, so as to improve detection Speed and detection accuracy, and the effect of reducing detection power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

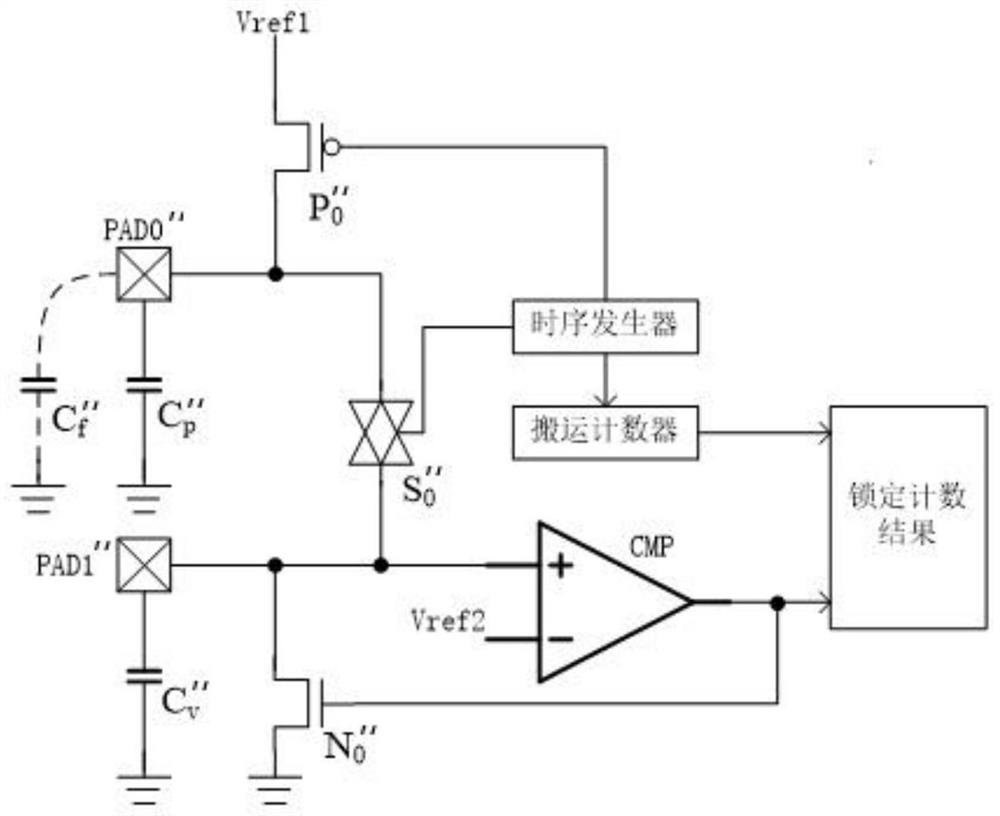

[0046] Such as Figure 4 As shown, a high-speed and low-power capacitive touch detection circuit includes a touch module and a successive approximation module. The touch module includes a charging power module and a comparison trigger module. The charging power module is respectively connected to the input side of the comparison trigger module and an external touch PAD. The output side of the comparison trigger module is connected with the successive approximation module.

[0047] Such as Figure 5 As shown, the charging power supply module includes a first current source I1, a second current source I2, a third current source I3, and a fourth current source I4. The output terminal of the first current source I1 is connected in parallel with a first capacitor C1 and a first resistor R1. The first resistor R1 is connected in series between the first current source I1 and the second current source I2, the output terminal of the second current source I2 is connected in parallel w...

Embodiment 2

[0075] Such as Figure 10 As shown, a high-speed low-power capacitive touch detection method is based on the high-speed low-power capacitive touch detection circuit described in Embodiment 1. The method steps include:

[0076] S1: Perform successive approximation calculations in sequence according to the current control bits of the first current source to obtain an output current value of the first current source;

[0077] Specifically, successive approximation calculations are performed sequentially according to the current control bit of the first current source, and the number of calculations is determined by the current control bit width of the first current source, that is, starting from the highest bit of the current control bit of the first current source until the first current source The last bit of the current control bit ends. First, set the RST reset signal to 1 through the successive approximation module, so that the first NOMS transistor N1, the second NOMS tran...

Embodiment 3

[0103] A high-speed and low-power capacitive touch detection chip includes the above-mentioned high-speed low-power capacitive touch detection circuit.

[0104] The chips provided in the embodiments of the present invention are for brief description, and for those not mentioned in the embodiments, reference may be made to the corresponding content in the foregoing embodiments.

[0105] The invention adopts the method of successive approximation for capacitive touch detection, improves the detection speed and detection accuracy, reduces the detection power consumption, and realizes fast multi-channel and multiple detection at the same time, and can detect the touch intensity by configuring different touch thresholds, and also With touch slide detection function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com