Magnetic ball calibration method and magnetic ball calibration device

A calibration method and calibration device technology, applied in the field of magnetic control, can solve problems such as complex operation, unfavorable application, and cumbersome process, and achieve the effects of simple operation, convenient control, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

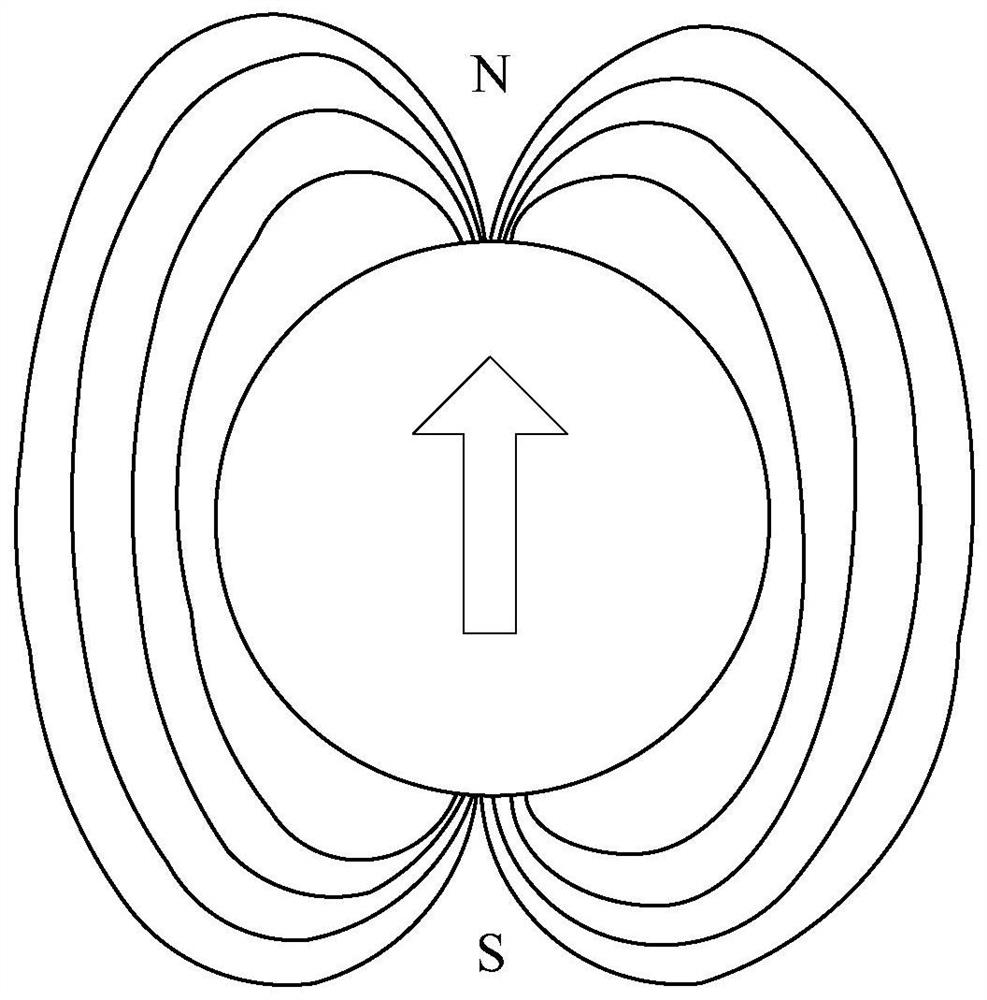

Problems solved by technology

Method used

Image

Examples

no. 2 example

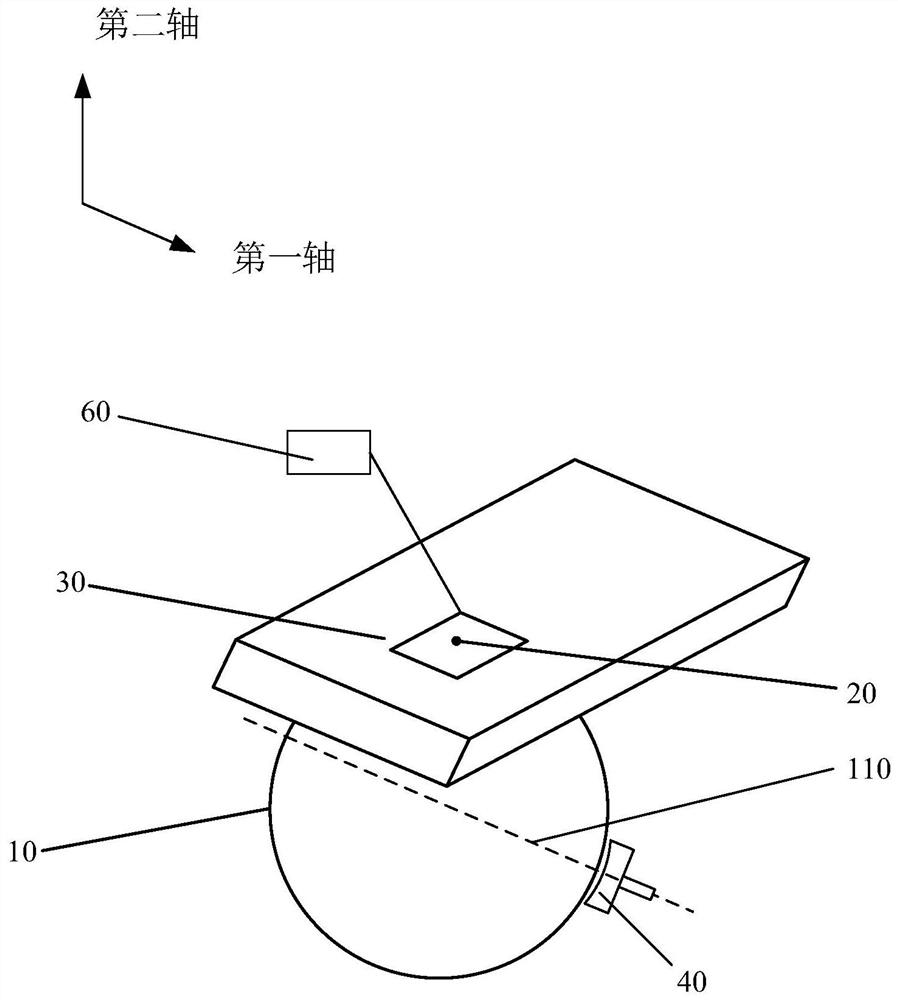

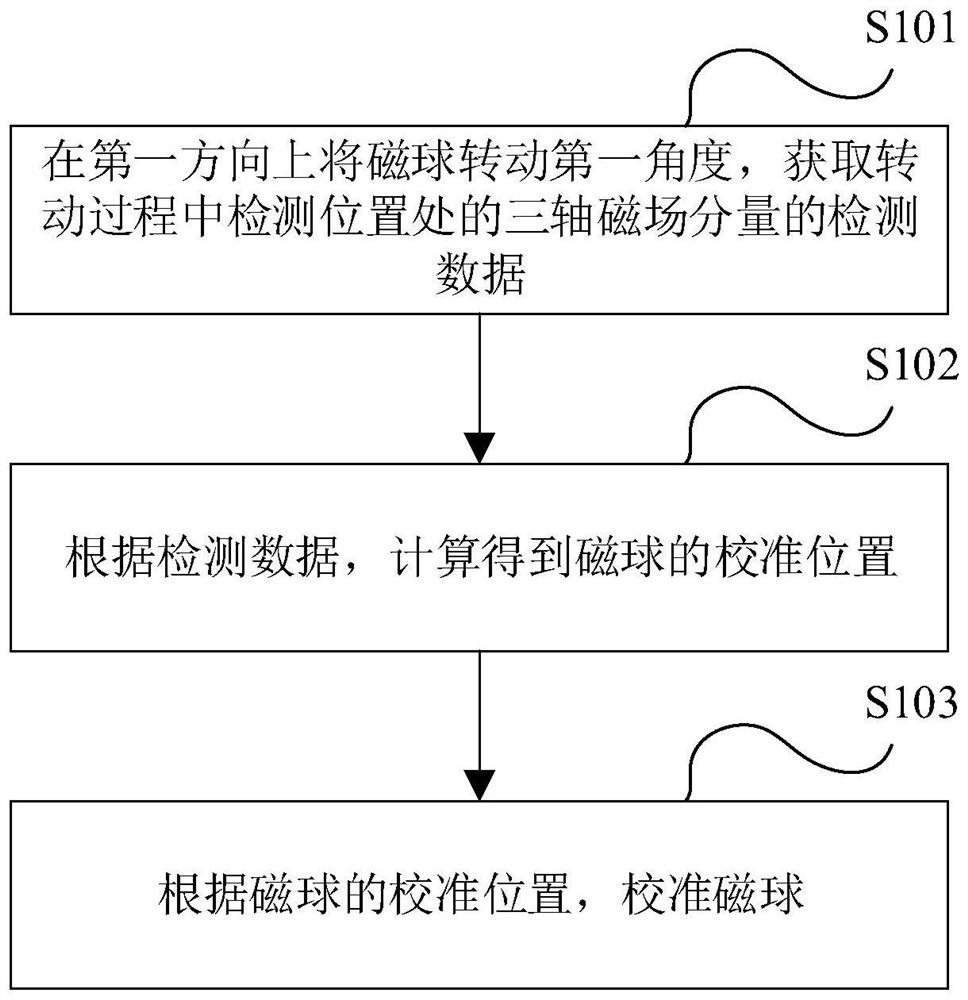

[0095] Such as Figure 4 Shown in (a), the second embodiment of the present invention comprises the following steps:

[0096] In step S201, the magnetic ball 10 is rotated by a first angle around a first axis.

[0097] The vertical rotation of the magnetic ball 10 means that the magnetic ball 10 rotates around the first axis 110 by a first angle, wherein the first angle is greater than 180°, such as 200°, so that during the rotation of the magnetic ball 10, the zero point position can be set to three degrees. The detection position of the axis magnetic sensor 20.

[0098] In step S202, the zero point position P where the magnetic field intensity component of the magnetic ball is zero in the direction of the second axis is obtained according to the detection data 0 ;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com