Spring type continuum robot system combined with flexible hinge

A robot system and flexible hinge technology, applied in the field of medical robots, can solve the problems of inability to achieve variable stiffness in different segments, small axial bearing capacity, axial deformation, etc., to solve the problem of insufficient axial bearing capacity and axial bearing capacity. Enhanced, easy-to-create effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

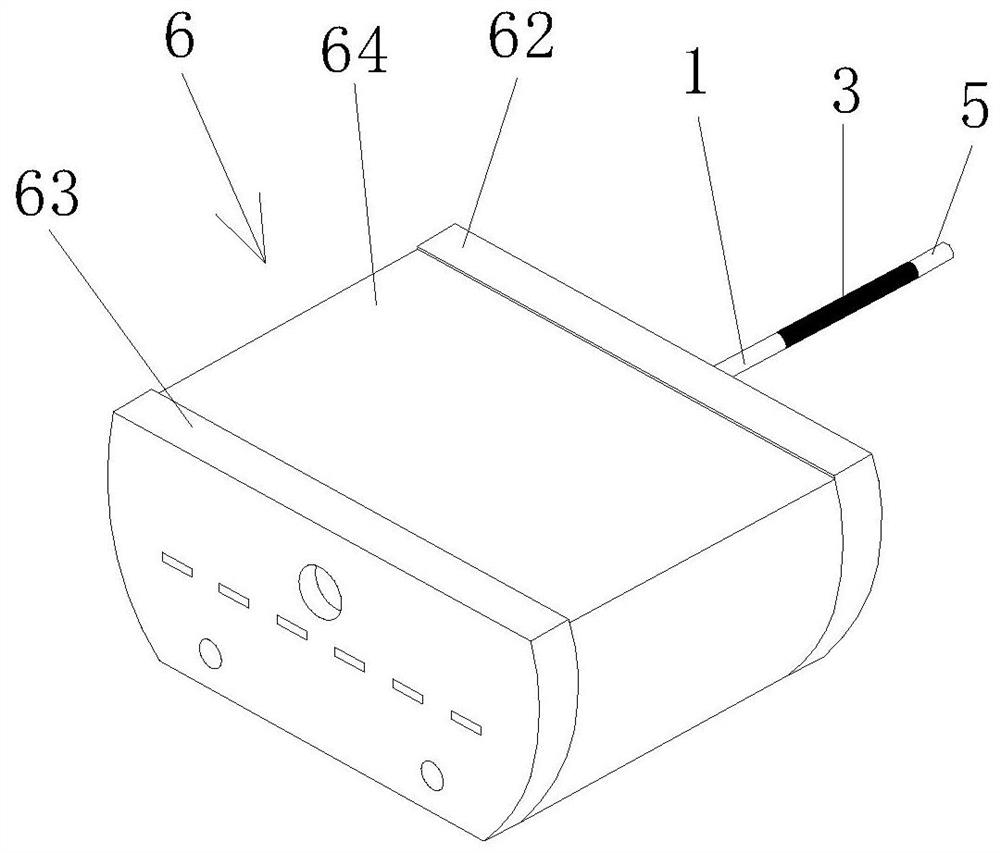

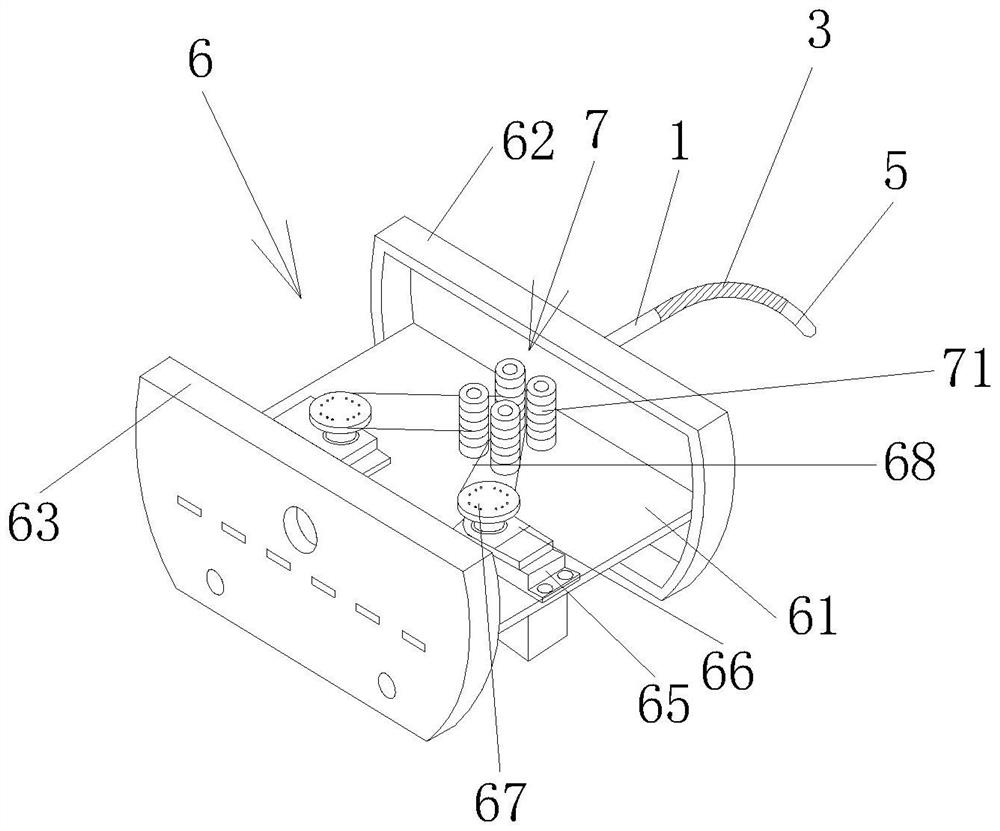

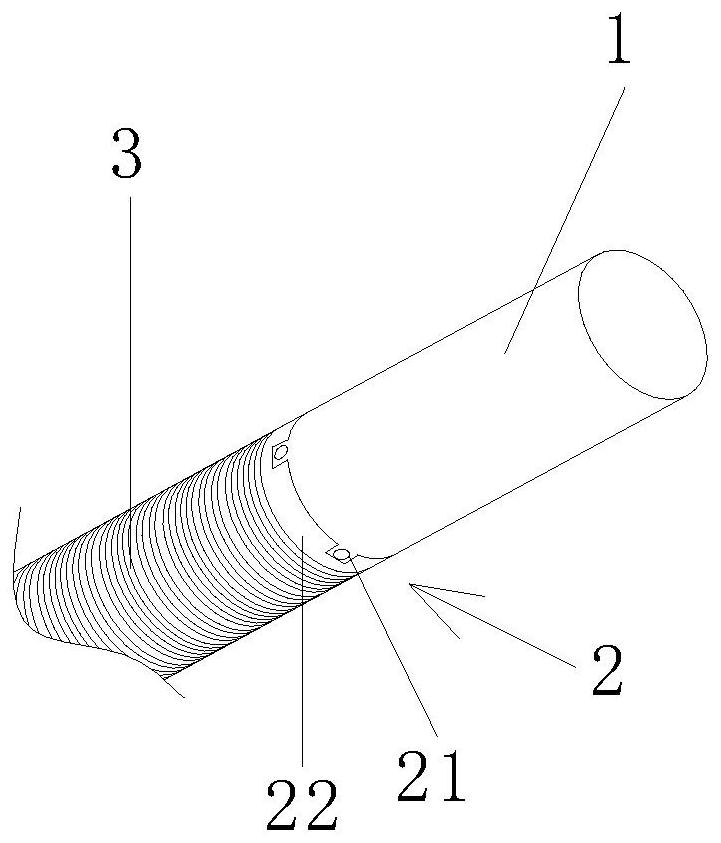

[0036] see Figure 1 to Figure 7 As shown, the present invention provides an embodiment: a spring-type continuum robot system combined with a flexible hinge, which includes a hollow cylinder 1, and the end of the hollow cylinder 1 is connected to a spring body 3 through a connecting piece 2. The spring main body 3 is provided with a cylindrical flexible hinge 4, and the end of the spring main body 3 is provided with a hollow connecting column 5 for placing an end effector; the front end of the hollow cylinder 1 is fixed to drive the spring main body 3 to bend on the drive mechanism 6. During surgery, different end effectors can be connected through the hollow connecting column 5 according to different surgical requirements, and then the driving mechanism 6 can drive the spring body 3 to bend, thereby realizing multi-directional movement.

[0037] read on figure 2As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com