Raw material reaction equipment for new medicine preparation

A technology of reaction equipment and medicine, which is applied in the field of raw material reaction equipment for new medicine production, can solve the problems of time-consuming and physical effort, cumbersome pharmaceutical process, and low efficiency of manual operation, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

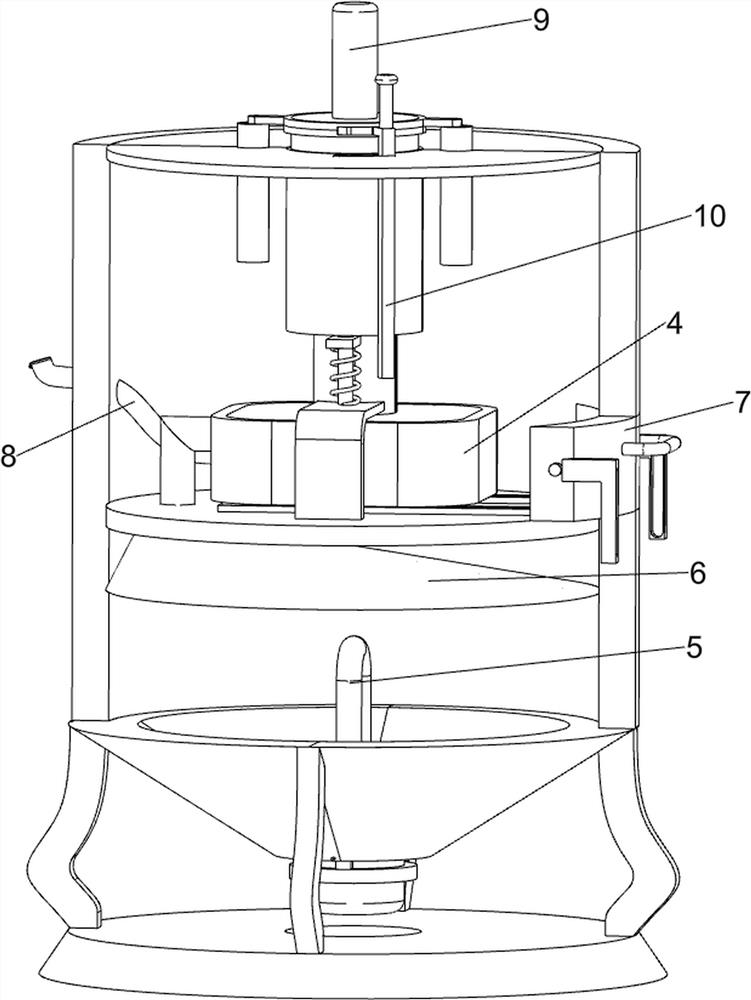

[0069] A raw material reaction equipment for new medicine production, such as Figure 1-Figure 7 As shown, it includes a bottom plate 1, a first support plate 2, a fumigation barrel 3, a plug 31, a fumigation box 4, a heating mechanism 5, a fumigation mechanism 6 and a discharge mechanism 7, and four first supports are evenly spaced on the top of the bottom plate 1 There is a fumigation barrel 3 between the top of the board 2 and the first support plate 2, a plug 31 is provided slidingly at the lower part of the front side of the fumigation barrel 3, a heating mechanism 5 is arranged in the middle of the bottom of the fumigation barrel 3, and a fumigation mechanism is arranged in the middle of the inner side of the fumigation barrel 3 6. The middle part of the right side of the fumigation barrel 3 is provided with a discharge mechanism 7, and the fumigation box 4 is slidingly provided on the discharge mechanism 7.

[0070]The heating mechanism 5 includes a first support block ...

Embodiment 2

[0075] On the basis of Example 1, such as figure 2 , Figure 8 and Figure 9 As shown, it also includes a decompression mechanism 8. The decompression mechanism 8 includes an air outlet pipe 80, a second baffle plate 81, a rotating rod 82 and a second spring 83. The upper left side of the fumigation barrel 3 is provided with an air outlet pipe 80, and the air outlet pipe The right side of 80 is slidably matched with the fumigation box 4, and the upper part of the left side of the air outlet pipe 80 is rotatably provided with a rotating rod 82, and the middle part of the rotating rod 82 is provided with a second baffle plate 81, and the second baffle plate 81 covers the top of the air outlet pipe 80. A second spring 83 is provided between the front and rear sides of 82 and the air outlet pipe 80 .

[0076] After the reaction of the liquid raw material and the medicinal material is finished, people can turn the second baffle plate 81 to the left to open, which drives the rota...

Embodiment 3

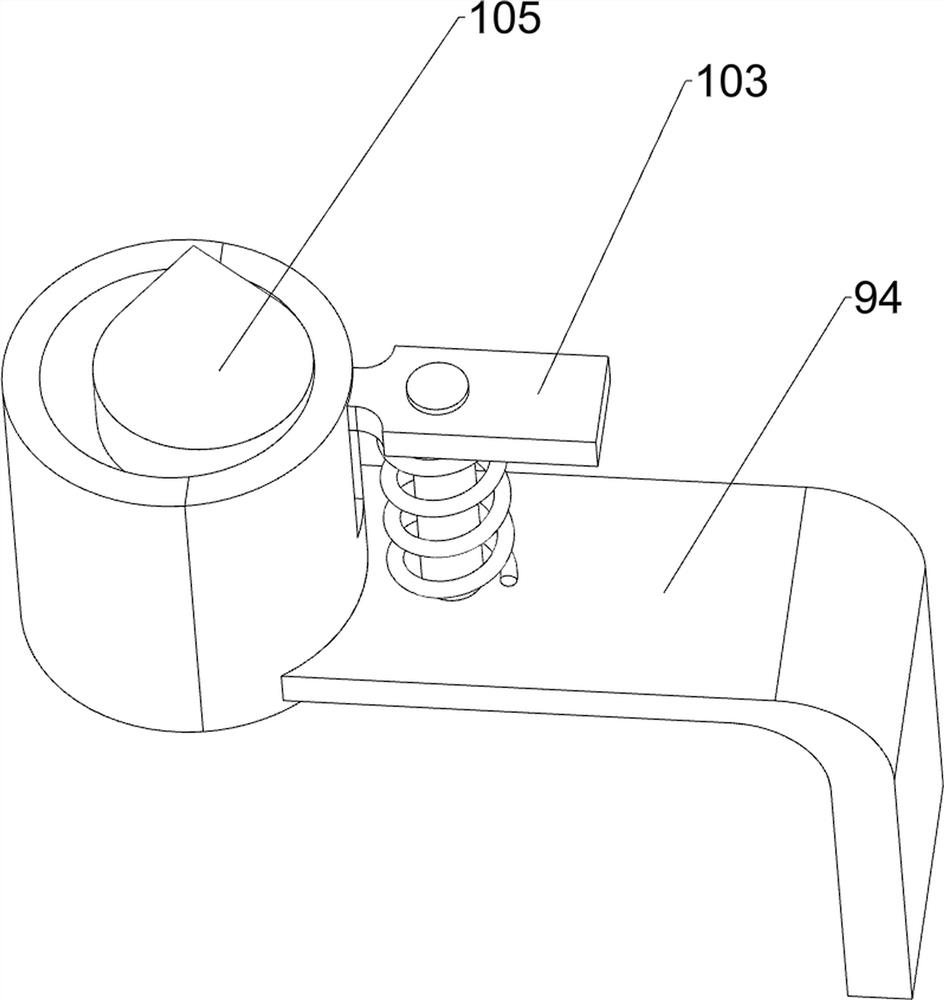

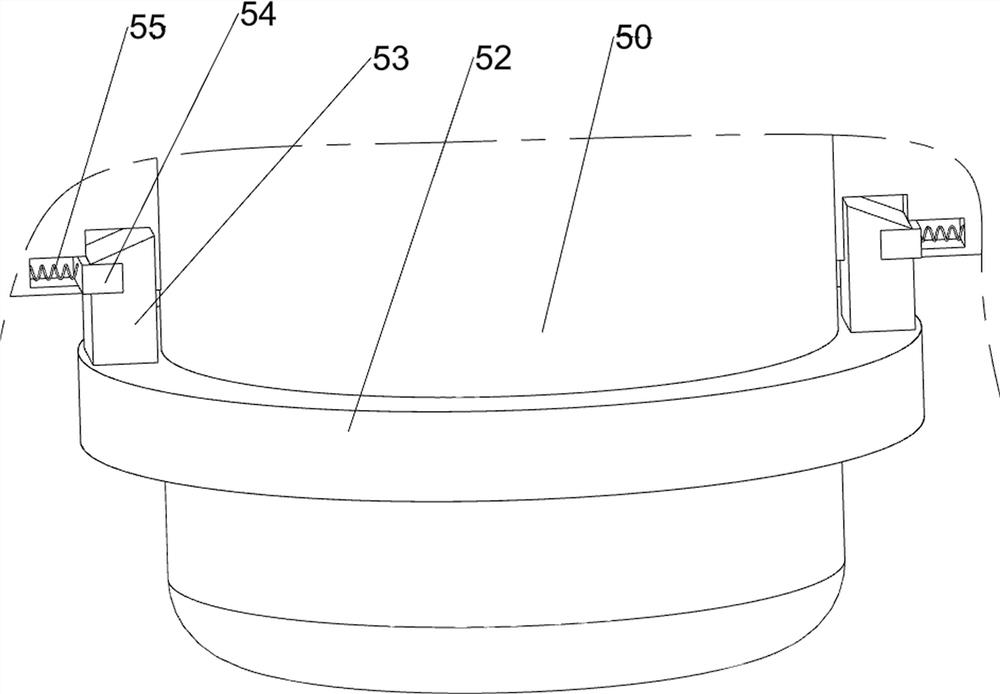

[0078] On the basis of Example 2, such as figure 2 , Figure 10 , Figure 11 , Figure 12 and Figure 13 Shown, also comprise mashing mechanism 9, and mashing mechanism 9 includes mashing barrel 90, second support block 91, guide cylinder 92, lower material cylinder 93, the 3rd support plate 94, cylinder 95, mashing block 96 And the 3rd spring 97, fumigation barrel 3 top middles are provided with pounding barrel 90, and fumigation barrel 3 tops are provided with guide tube 92 symmetrically, between guide tube 92 sliding type is provided with second support block 91, and second support plate 60 The top front side is provided with a third support plate 94, the third support plate 94 upper rear side is provided with a lower material cylinder 93, the top of the lower material cylinder 93 communicates with the bottom of the pounding barrel 90, and the middle of the second support block 91 top is provided with a cylinder 95 , the bottom of the telescopic rod of the cylinder 95 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com