Automatic grain impurity removal device

An automatic and impurity technology, applied in the fields of grain husking, grain finishing, grain processing, etc., can solve the problems of mixed quality, easy to block, bad grain, etc., to improve the quality of finished products, improve convenience, improve Efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

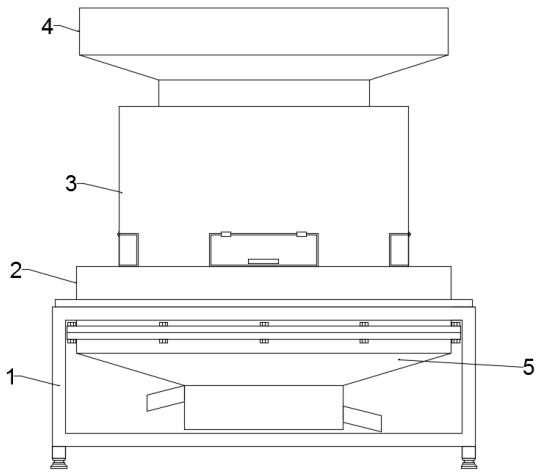

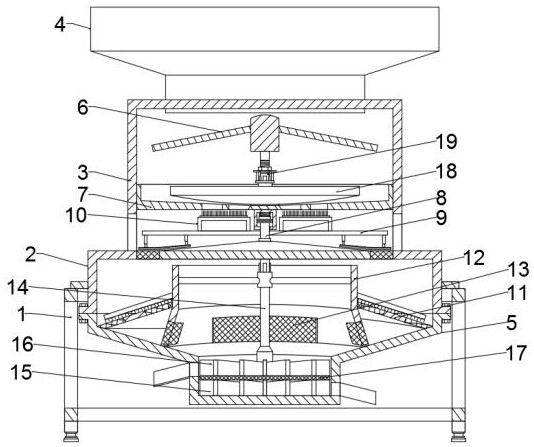

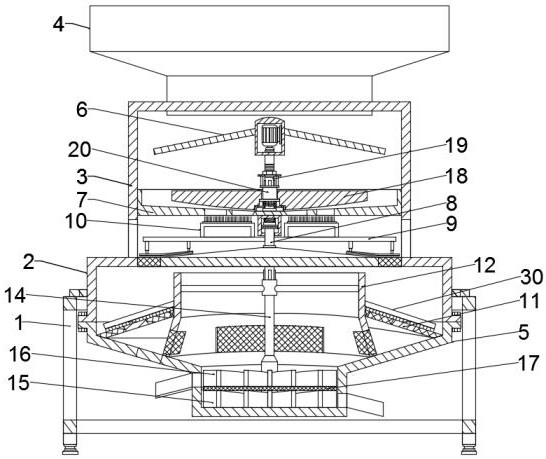

[0025] Example: see Figure 1-5 , an automatic removal device for grain impurities, comprising a mounting frame 1, a trash removal box 2 located on the top of the mounting frame 1, a shelling box 3 located at the top of the trash removal box 2 and a shelling box connected to the top of the shelling box 3 The shell box 3 and the bottom of the miscellaneous box 2 are equipped with a receiving hopper 5, and the upper part of the shelling box 3 is longitudinally provided with longitudinal beams, and the two sides of the longitudinal beams are all provided with diverter plates 6 whose outer ends are inclined downwards. A motor is provided in the middle, and a support plate 7 is horizontally fixed in the middle of the shelling box 3, and an arc-shaped rolling groove is provided on the top surface of the support plate 7; a rolling groove for grain husking is arranged in the rolling groove. Mechanism; the periphery of shelling box 3 outer wall bottoms is provided with miscellaneous ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com