Novel metal band sawing machine and operation method thereof

A metal belt and a new type of technology, applied in metal sawing equipment, sawing machine devices, metal processing equipment, etc., can solve the problems of rising power loss, unstable center of gravity of machine tools, and unequal stress points, and achieve stable stress structure. The effect of preventing pollution of the working environment and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

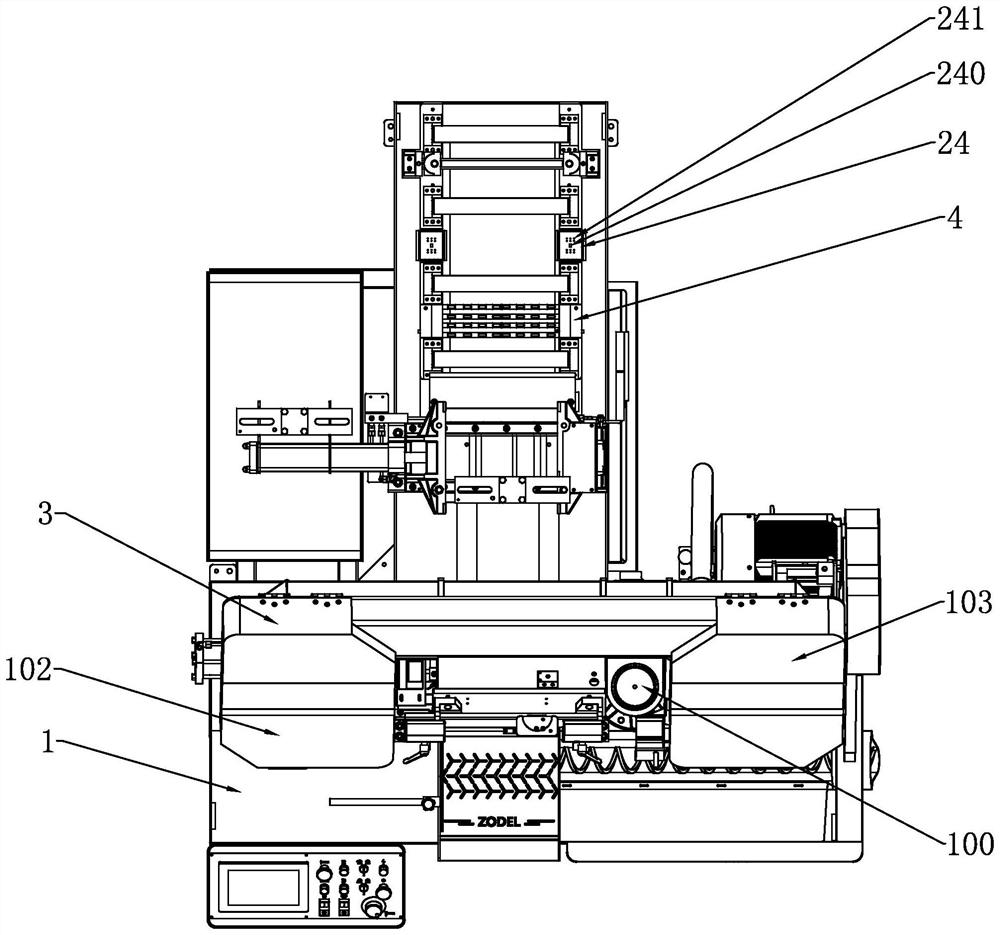

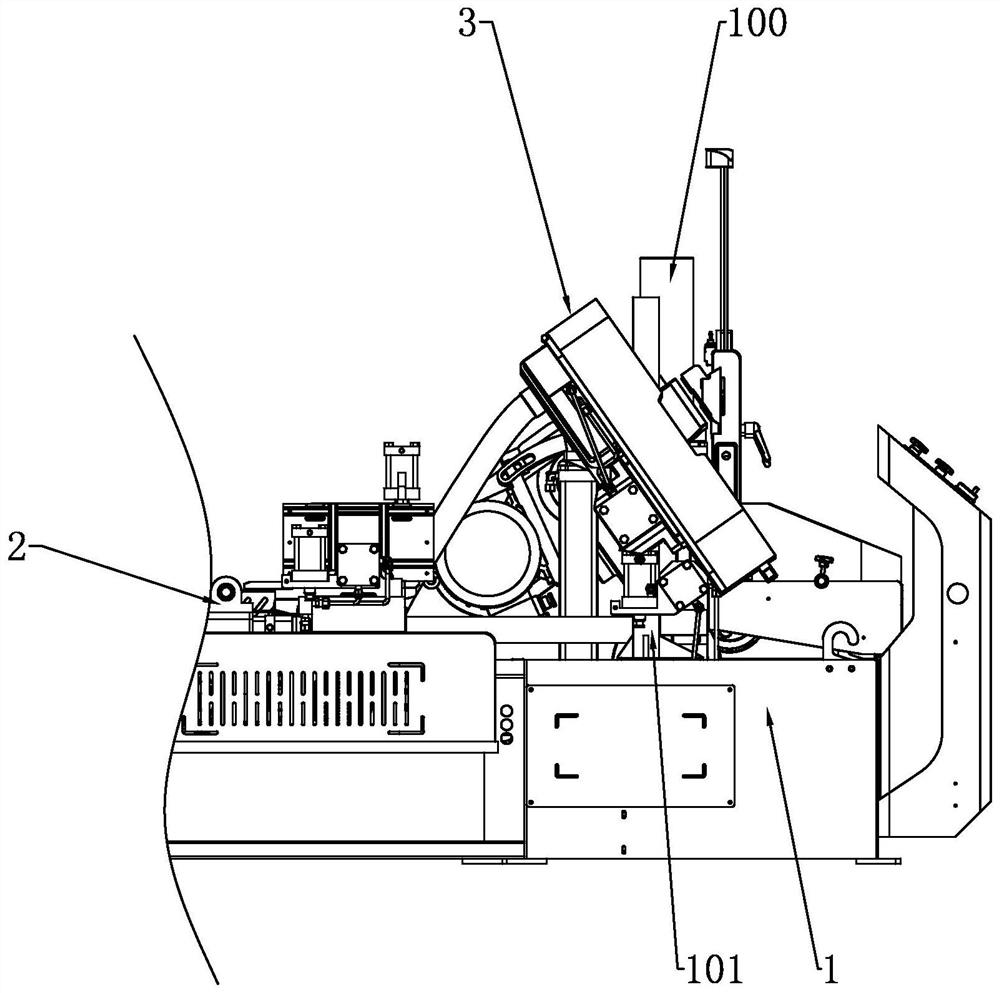

[0046] like Figure 1 to Figure 7 As shown, the embodiment of the present application provides a new type of metal band sawing machine, including a base 1, a feeding device 2, a transmission system, a saw frame 3, a guide, a cooling system and a hydraulic system, and also includes: a column, which includes a main column 100 And auxiliary column 101; Clamping device, clamping device comprises front clamping part and rear clamping part; Saw frame box, saw frame box comprises left saw frame box 102 and right saw frame box 103; Saw beam, saw beam is arranged on On the saw frame 3; the saw blade, the saw blade is arranged in the saw frame box; the main column 100 also includes: a lifting large column cover; the main column support structure, the main column support structure includes an adjustable lifting support seat; the auxiliary column 101 also includes: a support side column; guiding seat;

[0047] Among them, the transmission system is used to drive the saw blade, and the hydr...

Embodiment 2

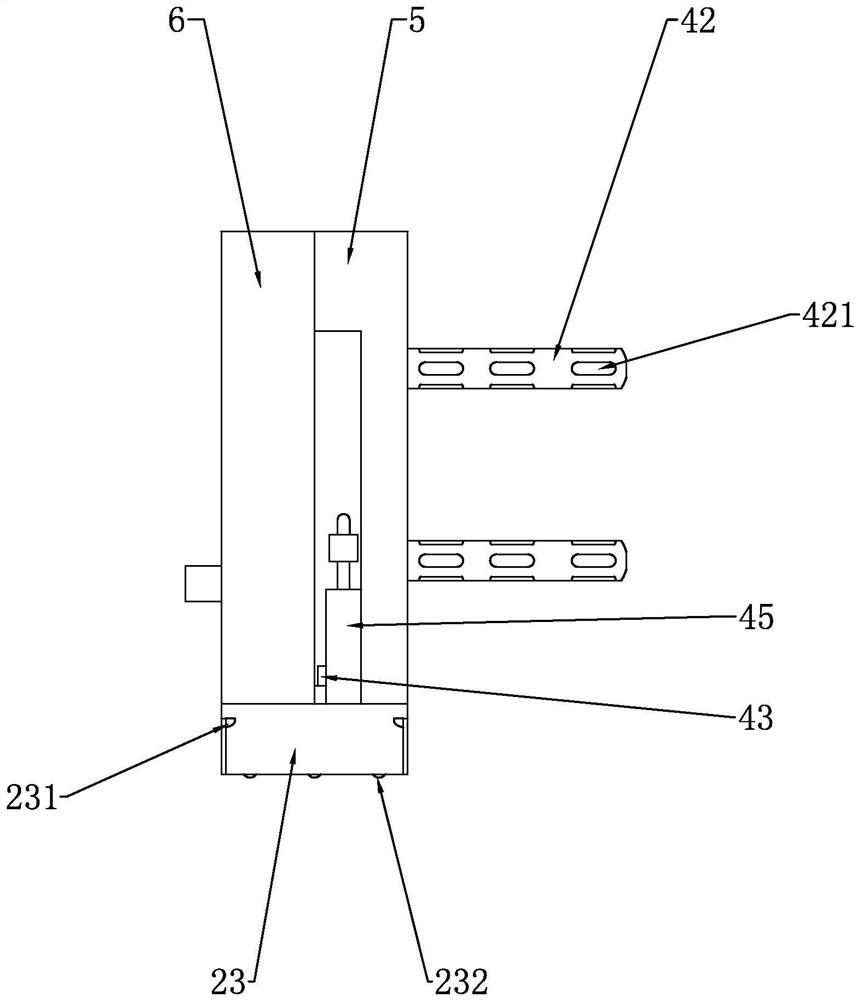

[0050] In this embodiment, in addition to including the structural features of the preceding embodiments, further feeding device 2 also includes: feeding rack 21, on which feeding rack 21 is provided with some feeding rollers 22; several cleaning units 4, and cleaning unit 4 is arranged on feeding rack 21 and between some feed rollers 22; the cleaning unit 4 also includes: an adsorption box 5, the left side wall of the adsorption box 5 is provided with some through holes; a cleaning box 6, and the cleaning box 6 is arranged on the right side of the adsorption box 5; Plate 41, mounting plate 41 is arranged in the adsorption box 5; Some telescopic adsorption rods 42, telescopic adsorption rods 42 are hollow rods, the rod wall of the telescopic adsorption rods 42 is provided with a wind chamber 420, and the telescopic adsorption rods 42 are provided with adsorption holes 421; blower 43, the blower 43 is arranged on the mounting plate 41, the blower 43 communicates with the air cha...

Embodiment 3

[0055] In this embodiment, in addition to the structural features of the foregoing embodiments, the further cleaning box 6 also includes: an air inlet cavity 61, a movable plug 7 is arranged in the air inlet cavity 61; a filter cavity 62, a filter plate is arranged in the filter cavity 62 8; the air outlet chamber 63, the second exhaust fan 9 and the electrical connection block 10 are arranged in the air outlet chamber 63; the cleaning chamber 64, the movable partition 11 and the water outlet 12 are arranged in the cleaning chamber 64; the water storage chamber 65, the storage chamber The water chamber 65 is provided with a piston 13; the transmission chamber 66, the transmission chamber 66 is provided with a transmission part; the transmission part also includes: a motor 14, the output end of the motor 14 is provided with a rotating rod 15, and the rotating rod 15 is provided with a driving gear 16 and driving pulley 17; Driven gear 161, driven gear 161 rotation is arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com