A mold for shape memory polymer blister

A technology of memory polymers and molds, which is applied to tubular objects, household appliances, and other household appliances. It can solve the problems of high cost, uneven pressure, loss and high wear and corrosion rate, so as to save cost and material loss and ensure smoothness. degree, the effect of stress structure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

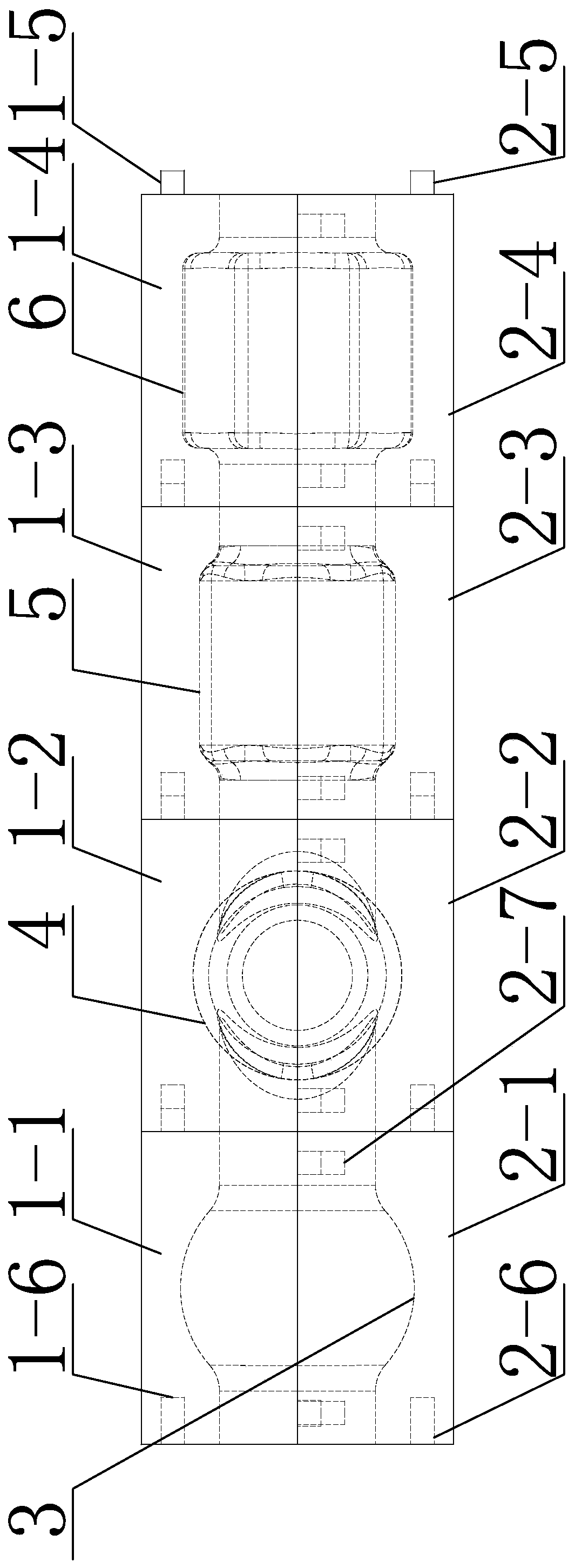

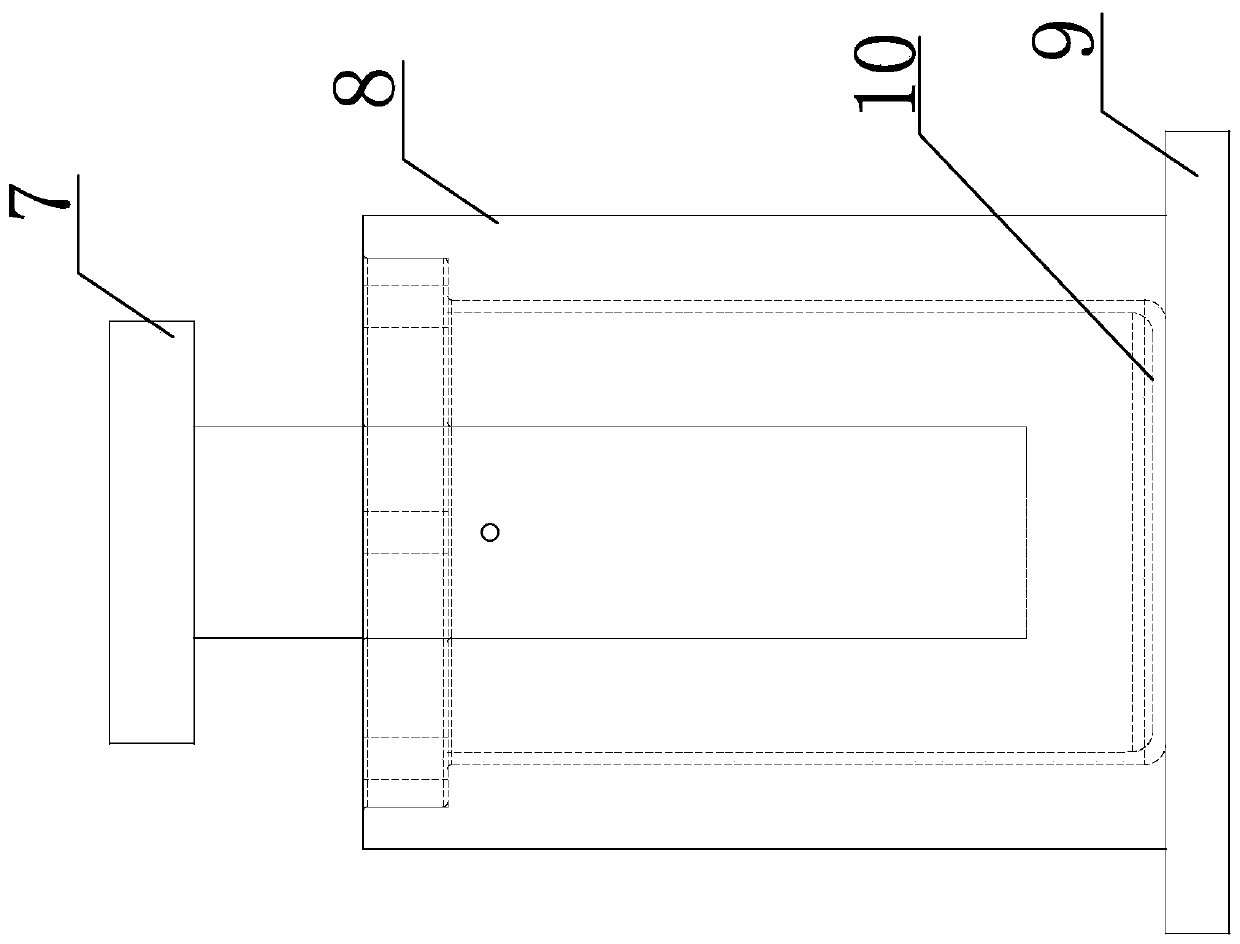

[0013] Embodiment 1: Combining figure 1 Illustrating this embodiment, a mold for shape memory polymer blistering described in this embodiment includes an upper mold body 1 and a lower mold body 2, and the upper mold body 1 and the lower mold body 2 are relatively fastened to form a rectangular parallelepiped, The cuboid is machined with a cavity along the length direction.

specific Embodiment approach 2

[0014] Specific implementation mode 2: Combining figure 1 Illustrating this embodiment, a mold for shape memory polymer blister molding described in this embodiment, the upper mold body 1 includes a first upper mold body 1-1, a second upper mold body 1-2, and a third upper mold Body 1-3 and the fourth upper mold body 1-4, one end of the first upper mold body 1-1 is machined with two first cylindrical protrusions 1-5, and the other end of the first upper mold body 1-1 is machined There are two first circular grooves 1-6 corresponding to the two first cylindrical protrusions 1-5, and one end of the second upper mold body 1-2 is machined with two first cylindrical protrusions 1-5 , the other end of the second upper mold body 1-2 is machined with two first circular grooves 1-6 corresponding to the two first cylindrical protrusions 1-5, and one end of the third upper mold body 1-3 Two first cylindrical protrusions 1-5 are machined, and the other end of the third upper mold body 1-...

specific Embodiment approach 3

[0015] Specific implementation three: combination figure 1 Illustrating this embodiment, a mold for shape memory polymer blister molding described in this embodiment, the lower mold body 2 includes a first lower mold body 2-1, a second lower mold body 2-2, and a third lower mold The body 2-3 and the fourth lower mold body 2-4, one end of the first lower mold body 2-1 is machined with two second cylindrical protrusions 2-5, and the other end of the first lower mold body 2-1 is machined There are two second circular grooves 2-6 corresponding to the two second cylindrical protrusions 2-5, and one end of the second lower mold body 2-2 is machined with two second cylindrical protrusions 2-5 , the other end of the second lower mold body 2-2 is machined with two second circular grooves 2-6 corresponding to the two second cylindrical protrusions 2-5, and one end of the third lower mold body 2-3 Two second cylindrical protrusions 2-5 are machined, and the other end of the third lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com