Preparation process and equipment of physical foaming material

A technology of physical foaming and equipment, which is applied in the field of the preparation process of physical foaming materials and its equipment, can solve the problems of the extruder is not easy to work, the temperature is uncontrollable, and the production fault tolerance rate is low, so as to improve the production fault tolerance rate. , avoid sedimentation, increase the effect of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

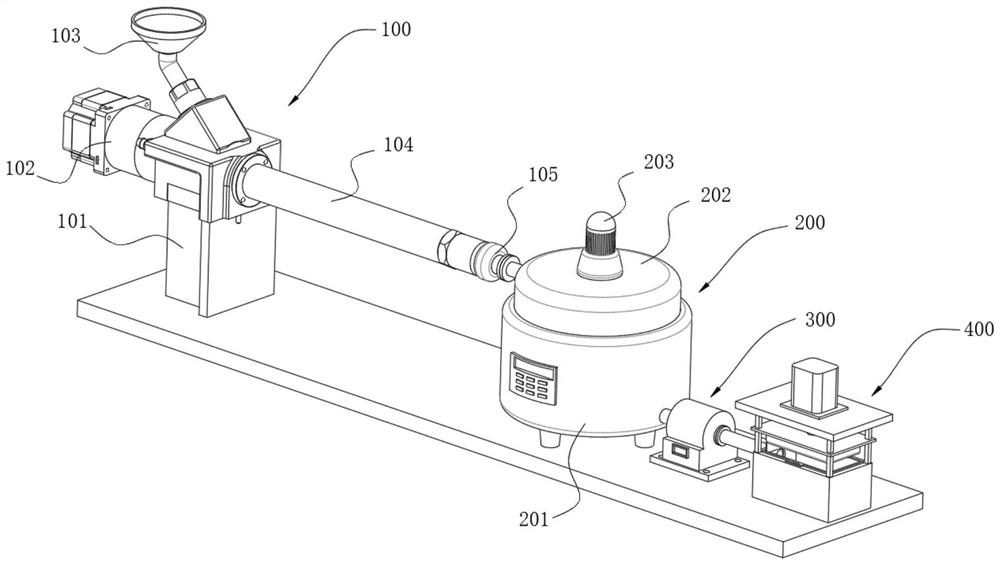

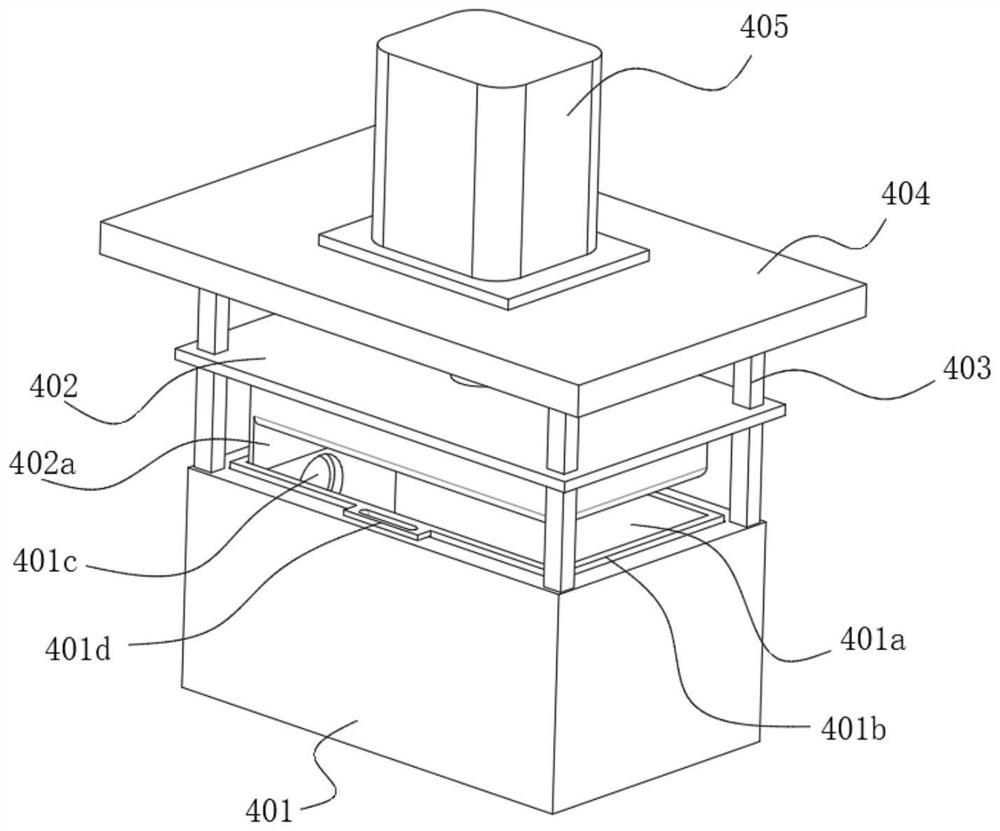

[0038] refer to Figure 1-5 , as an embodiment of the present invention, proposes a physical foaming material preparation equipment, including extrusion unit 100 , storage unit 200 , shaping unit 400 and metering pump 300 .

[0039] The extrusion unit 100 includes a base 101, an extrusion motor 102 installed on one side of the base 101, an extrusion sleeve 104 disposed on the other side of the base 101, and an extrusion sleeve 104 disposed on the base 101 and connected to the extrusion sleeve. The barrel 104 is connected to the feeding barrel 103, and the feeding port of the extrusion sleeve 104 is fixedly connected with an extruder head 105;

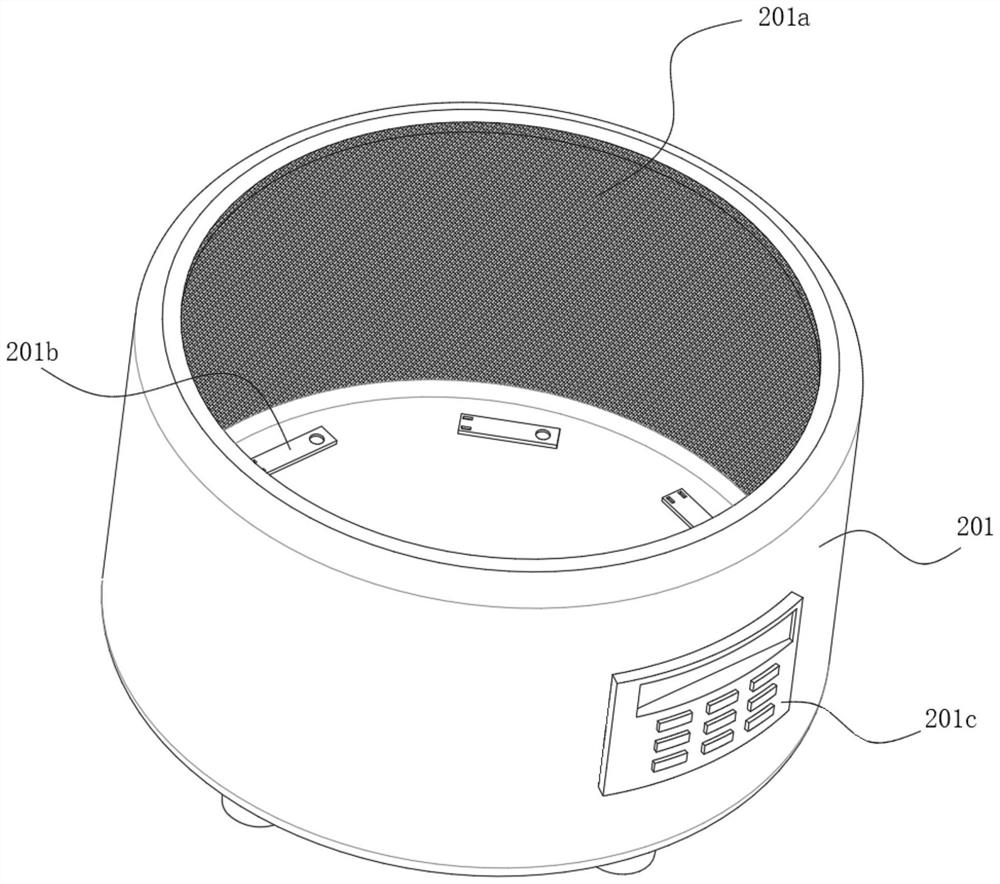

[0040]The material storage unit 200 includes an outer heating cylinder 201, an inner storage cylinder 202 arranged inside the outer heating cylinder 201, and a stirring motor 203 installed on the inner storage cylinder 202, the outer heating cylinder 201 and the inner storage cylinder 202 are hermetically connected, and The outer heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com