3D printing device and method

A 3D printing and printing platform technology, applied in the field of 3D printing, can solve problems such as restricted application, low degree of fuse bonding, and performance defects of printed parts, so as to achieve the effect of improving performance and reducing the degree of anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The ordinary printing platform is used, and the vibration of the platform is not excited.

Embodiment 2

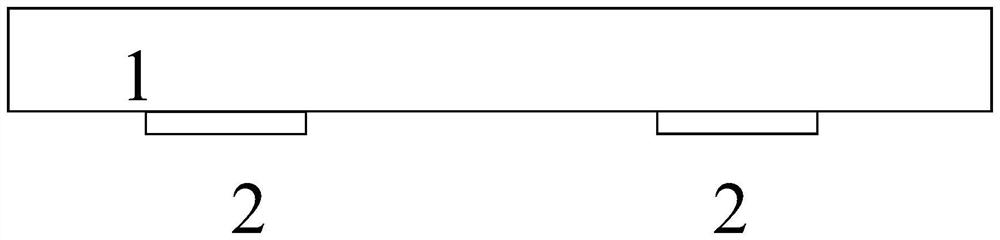

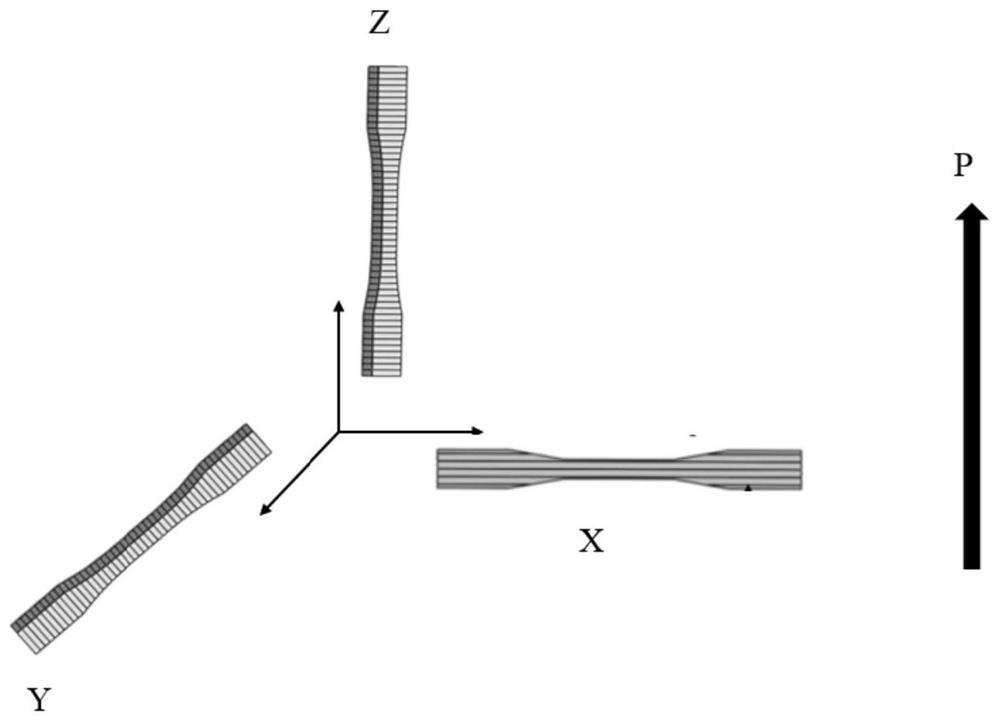

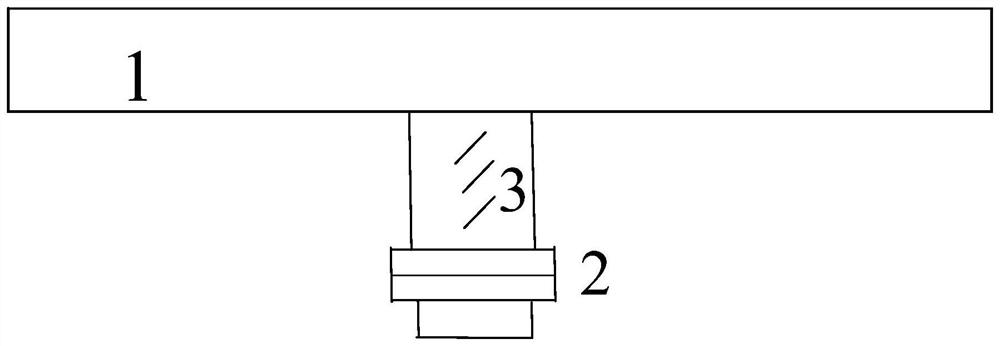

[0028] refer to figure 1 and figure 2 , this embodiment provides a 3D printing device, including: a printing platform 1, two piezoelectric ceramics 2 are arranged below the printing platform 1, and the two piezoelectric ceramics 2 are used to excite the two-phase vibration mode of the printing platform, Through the superposition and combination of the two-phase vibration modes, the particles on the surface of the printing platform generate elliptical motion. The vibration frequency is controlled by controlling the input voltage of the battery ceramic sheet 3. In this embodiment, the effective value of the applied voltage is 40V, and the plateau amplitude is 1 micron.

[0029] It should be noted, figure 2 Among them, X, Y, and Z are three-dimensional coordinates, among which Z is the vertical direction, and P is the stacking and forming direction of 3D printing.

[0030] What needs to be explained here is that the vibration of the piezoelectric ceramic 2 excites the two vi...

Embodiment 3

[0033] The difference between this embodiment and Embodiment 2 is that four pieces of piezoelectric ceramics are installed under the printing platform, the effective value of the applied voltage is 120V, and the amplitude of the platform is 20 microns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com