Hybrid vehicle, starting control method, distribution system and vehicle-mounted controller

A hybrid vehicle and on-board controller technology, applied in the vehicle field, can solve problems such as low battery remaining power, torque performance limitation, motor function failure, etc., to achieve the effect of improving the safety and reliability of use, and improving the starting method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

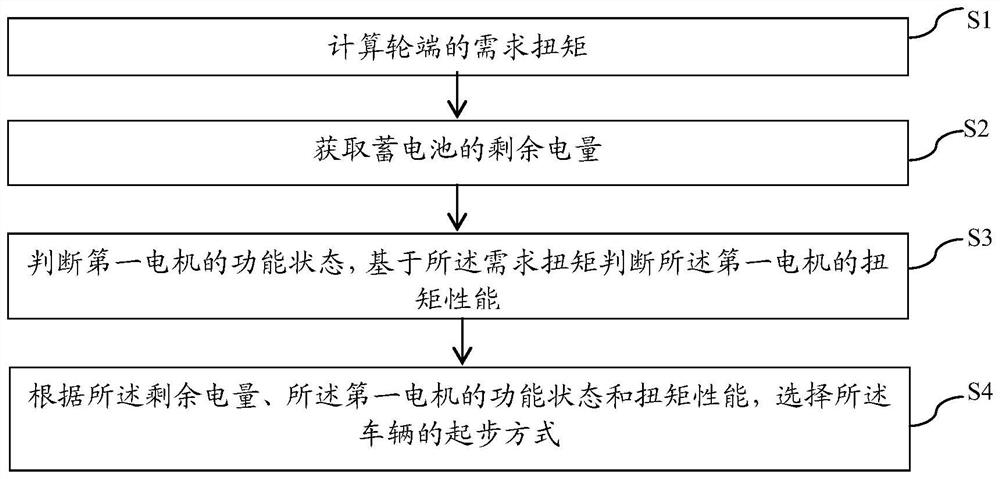

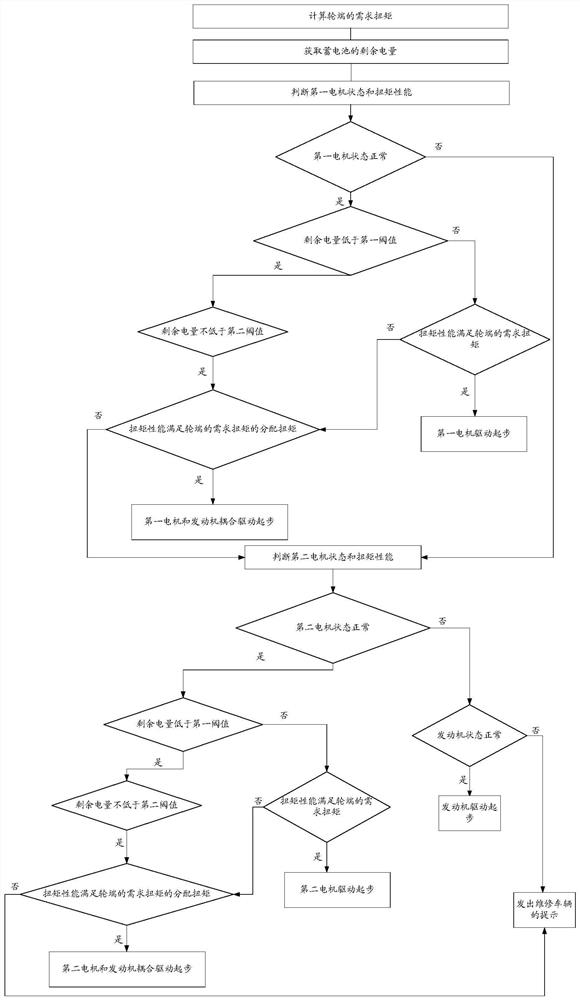

[0080] Implementation Mode 1: EV1 Mode

[0081] When the functional state of the first motor 6 is normal and the torque performance is satisfactory, the remaining power of the battery is greater than or equal to the first threshold, and the first motor 6 meets the required torque at the wheel end, the first motor 6 drives the vehicle to start.

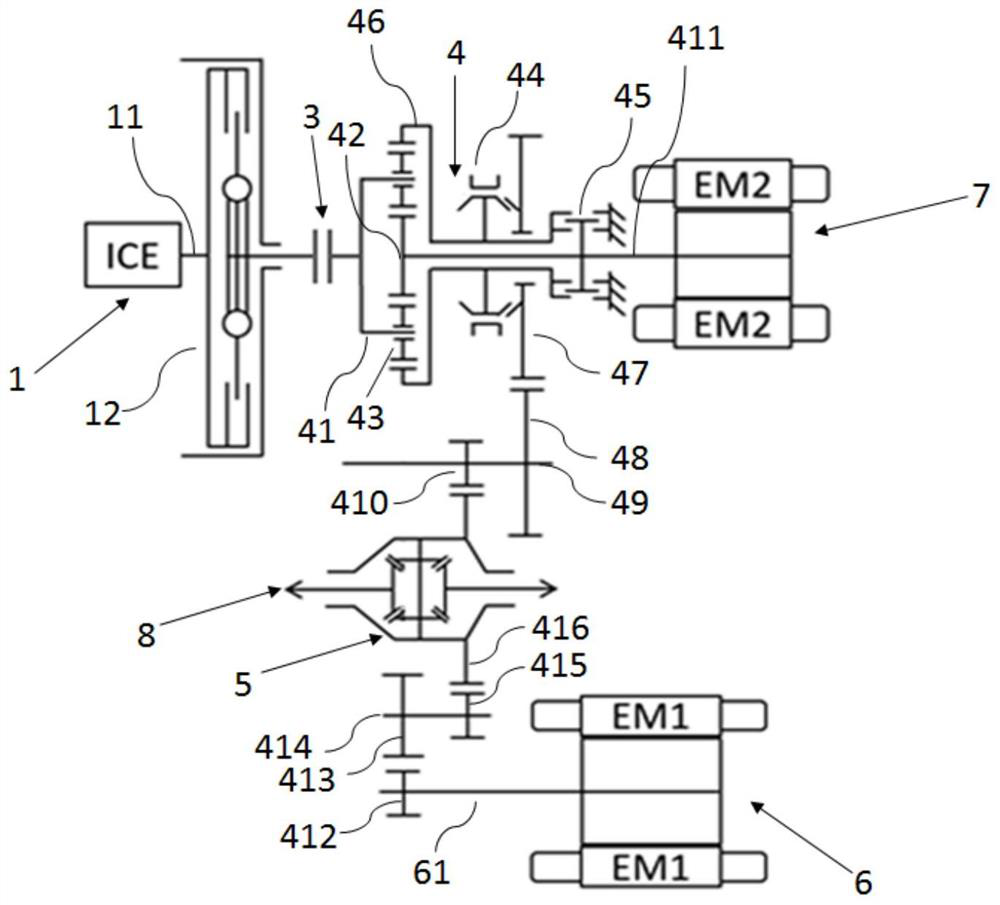

[0082] In one embodiment, see Figure 4 , when the clutch 3 is opened, the first synchronizer 44 is opened and the second synchronizer 45 is opened, the engine 1 does not work, and the power for driving the wheels is provided by the first motor 6 . The output power of the first motor 6 is output to the fourth gear 412 through the first motor shaft 61, and transmitted to the differential through the fourth gear 412, the fifth gear 413, the fifth gear shaft 414, the sixth gear 415 and the seventh gear 416. 5, and then drive the wheels through the output shaft 8 to start.

[0083] Exemplarily, in the EV1 mode, the execution torque of th...

Embodiment approach 2

[0084] Implementation Mode 2: ECVT1 Mode

[0085] When the functional state of the first motor 6 is normal and the torque performance is satisfied, the remaining power is greater than or equal to the first threshold, or the remaining power is greater than or equal to the second threshold and less than the first threshold, and the first motor 6 does not meet the required torque, but meets the required torque When the torque is distributed, the first motor 6 is coupled with the engine 1 to drive the vehicle to start.

[0086] In one embodiment, see Figure 5, when the clutch 3 is engaged, the first synchronizer 44 is engaged and the second synchronizer 45 is opened, the engine 1 works, and the power for driving the wheels is provided by the first motor 6 and the engine 1 . The output power of the engine 1 passes through the torsional shock absorber 12, the clutch 3, the planetary gear carrier 41, the planetary gear 43, the planetary ring gear 46, the first synchronizer 44, the ...

Embodiment approach 3

[0087] Implementation Mode 3: ECVT2 Mode

[0088] In one embodiment, see Figure 6 , when the clutch 3 is engaged, the first synchronizer 44 is engaged and the second synchronizer 45 is opened, the engine 1 works, and the power for driving the wheels is provided by the first motor 6 and the engine 1 . The engine 1 can drive the second motor 7 to charge the storage battery, that is, the second motor 7 can generate electricity.

[0089] For example, in the ECVT2 mode, referring to the torque set in the vehicle torque MAP, the output torques of the engine 1 and the first motor 6 are proportionally coupled and output to the wheel ends to drive the wheels to rotate, so that the vehicle can start normally. Specifically, it is divided into two initial stages. In the first stage of starting, due to the low remaining power, the engine 1 is directly connected to the second motor 7 to drive the second motor 7 to generate electricity with the highest efficiency. The second motor 7 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com