Self-repairing PDMS coating and preparation method thereof

A self-healing and coating technology, used in alginic acid coatings, coatings, etc., can solve problems such as reducing the mechanical properties of substrates or coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

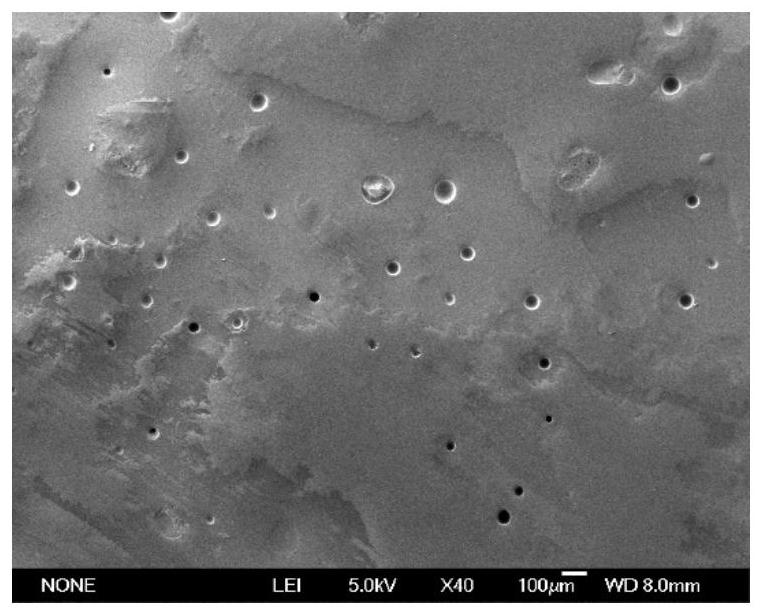

Embodiment 1

[0035] (1) Place 1 mg of PDMS in an oxygen environment, and use ultraviolet rays with a wavelength of 320 nanometers to irradiate the oxygen to make the oxygen generate oxygen-rich groups. After 50 minutes, put it into a 30% ethanol solution and take it out for 30 minutes; the surface of PDMS is grafted with hydroxyl ;

[0036] (2) Add PDMS with hydroxyl groups to 0.1M potassium permanganate solution and soak for 10 hours, so that hydroxyl groups are oxidized into carboxyl groups;

[0037] (3) Add 1mg of aminopolyethylene glycol hydroxyl groups to PDMS with carboxyl groups, and the carboxyl groups grafted on the surface of PDMS react to form amino groups.

[0038] (4) Mix 1mg of calcium alginate-based microcapsules and 0.4mg of EDC in 200mL of water at room temperature (20-30°C). After 2 hours, EDC reacts with the carboxyl groups of calcium alginate-based microcapsules to form amine-reactive O-acylisourea intermediate;

[0039] (5) Disperse the above O-acylisourea intermedia...

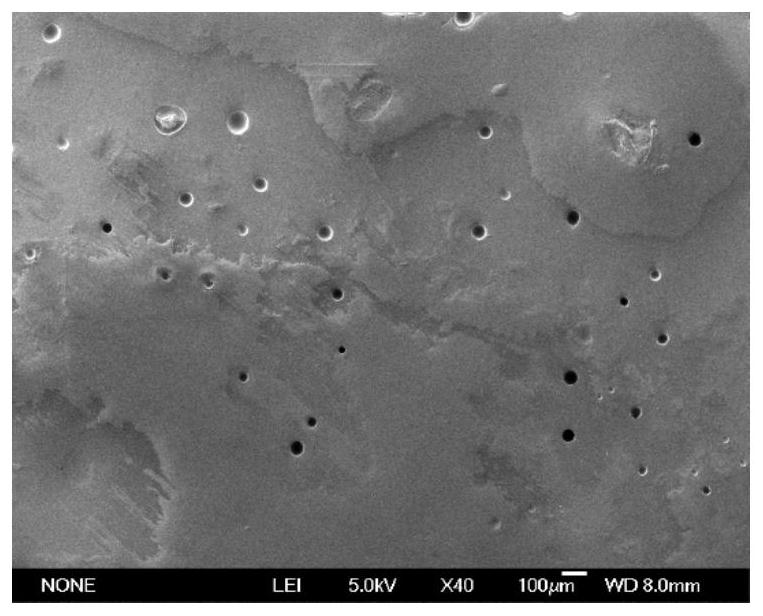

Embodiment 2

[0041] (1) Put 1 mg of PDMS in an oxygen environment, irradiate the oxygen with ultraviolet rays with a wavelength of 350 nanometers to generate oxygen-rich groups in the oxygen, and after 60 minutes, put it into a 30% ethanol solution for 30 minutes and take it out; the surface of PDMS is grafted with hydroxyl ;

[0042] (2) Add PDMS with hydroxyl groups to 0.1M potassium permanganate solution and soak for 12 hours, so that the hydroxyl groups are oxidized into carboxyl groups;

[0043] (3) Add 1mg of aminopolyethylene glycol hydroxyl groups to PDMS with carboxyl groups, and the carboxyl groups grafted on the surface of PDMS react to form amino groups.

[0044] (4) Mix 1mg of calcium alginate-based microcapsules and 0.4mg of EDC in 200mL of water at room temperature (20-30°C). After 3 hours, EDC reacts with the carboxyl groups of calcium alginate-based microcapsules to form amine-reactive Aqueous solution of O-acylisourea intermediate;

[0045] (5) Disperse the above O-acyl...

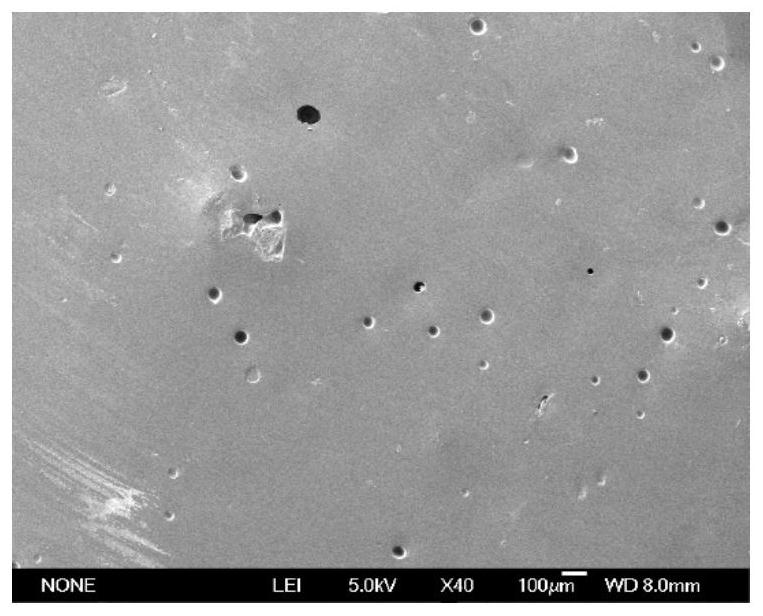

Embodiment 3

[0047] (1) Put 1 mg of PDMS in an oxygen environment, irradiate the oxygen with ultraviolet rays with a wavelength of 380 nanometers to generate oxygen-rich groups in the oxygen, and after 90 minutes, put it into a 30% ethanol solution and take it out for 30 minutes; the surface of PDMS is grafted with hydroxyl ;

[0048] (2) Add PDMS with hydroxyl groups to 0.1M potassium permanganate solution and soak for 15 hours, so that hydroxyl groups are oxidized into carboxyl groups;

[0049] (3) Add 1 mg aminopolyethylene glycol hydroxyl group to the PDMS solution with carboxyl groups, and the carboxyl groups grafted on the surface of PDMS react to form amino groups.

[0050] (4) Mix 1mg of calcium alginate-based microcapsules and 0.4mg of EDC in 200mL of water at room temperature (20-30°C). After 3 hours, EDC reacts with the carboxyl groups of calcium alginate-based microcapsules to form amine-reactive Aqueous solution of O-acylisourea intermediate;

[0051] (5) Disperse the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com