Probiotic powder preparation technology

A preparation process and technology of probiotics, applied in bacteria, lighting and heating equipment, packaging, etc., can solve the problems of probiotic material damage and long processing time of probiotic powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

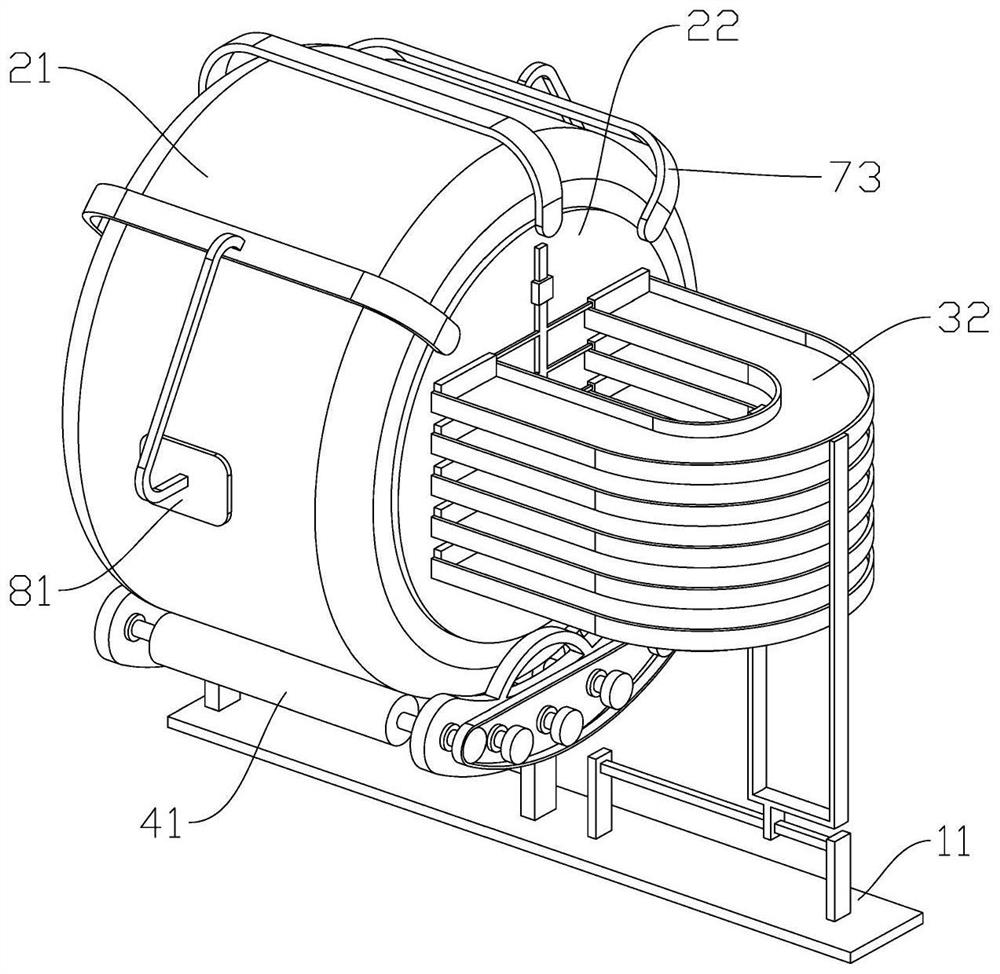

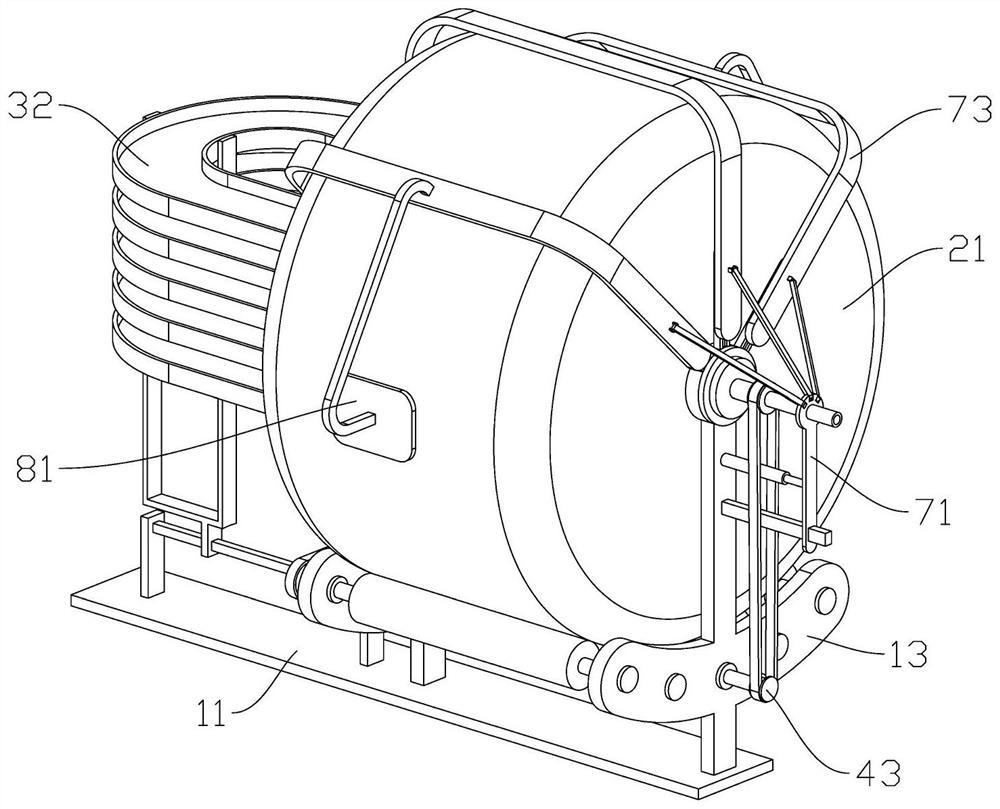

[0025] A preparation process of a probiotic powder provided by the present invention is described in detail with reference to the drawings in the embodiments of the present invention.

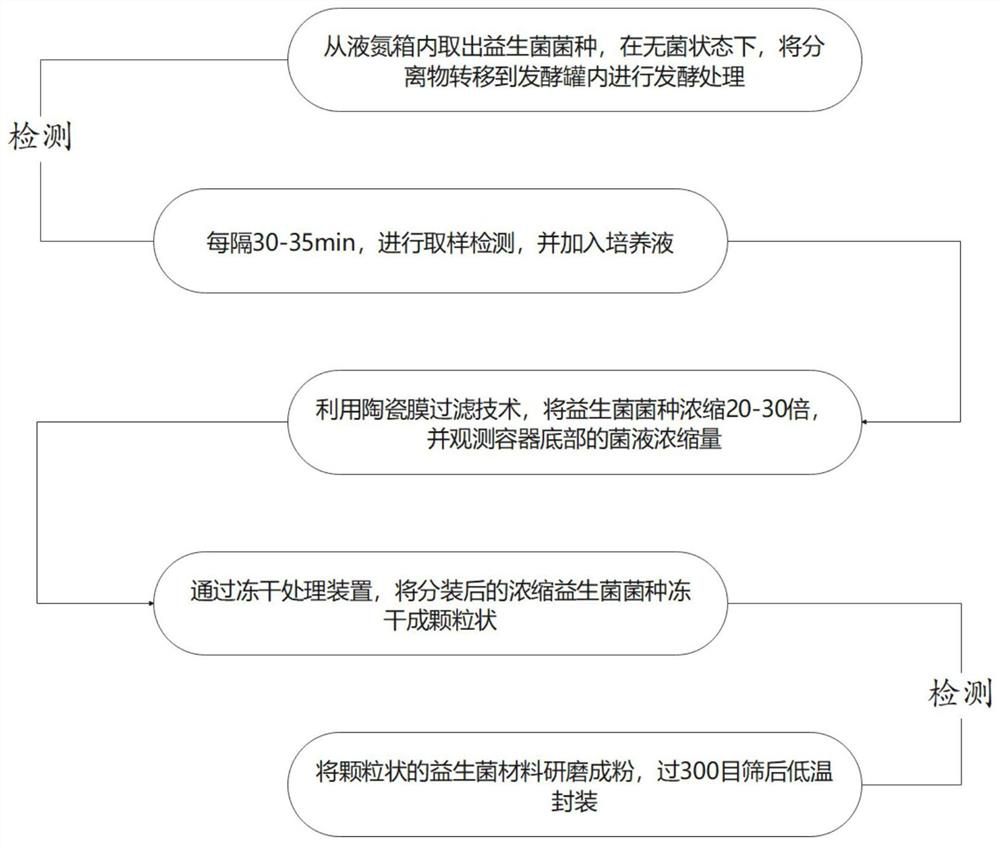

[0026] A kind of probiotic powder preparation process, comprises the following steps:

[0027] Step 1: Take out the probiotic strains from the liquid nitrogen tank, and transfer the isolate to a fermenter for fermentation in a sterile state;

[0028] Step 2: Sampling and testing every 32 minutes, and adding culture medium;

[0029] Step 3: Use ceramic membrane filtration technology to concentrate the probiotic strains by 25 times, and observe the concentration of the bacteria liquid at the bottom of the container;

[0030] Step 4: Use the freeze-intervention treatment device to reduce the water content in the concentrated probiotic strains after packaging, and finally freeze-dry the concentrated probiotic strains into granules through vacuum drying equipment;

[0031] Step 5: Grinding the gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com