Degradable electronic packaging blister tray

A tray and electronic technology, which is applied in the field of degradable electronic packaging blister trays, can solve the problems that the tray does not have degradability and the items are difficult to remove, and achieves the effect of improving the stability of placement and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

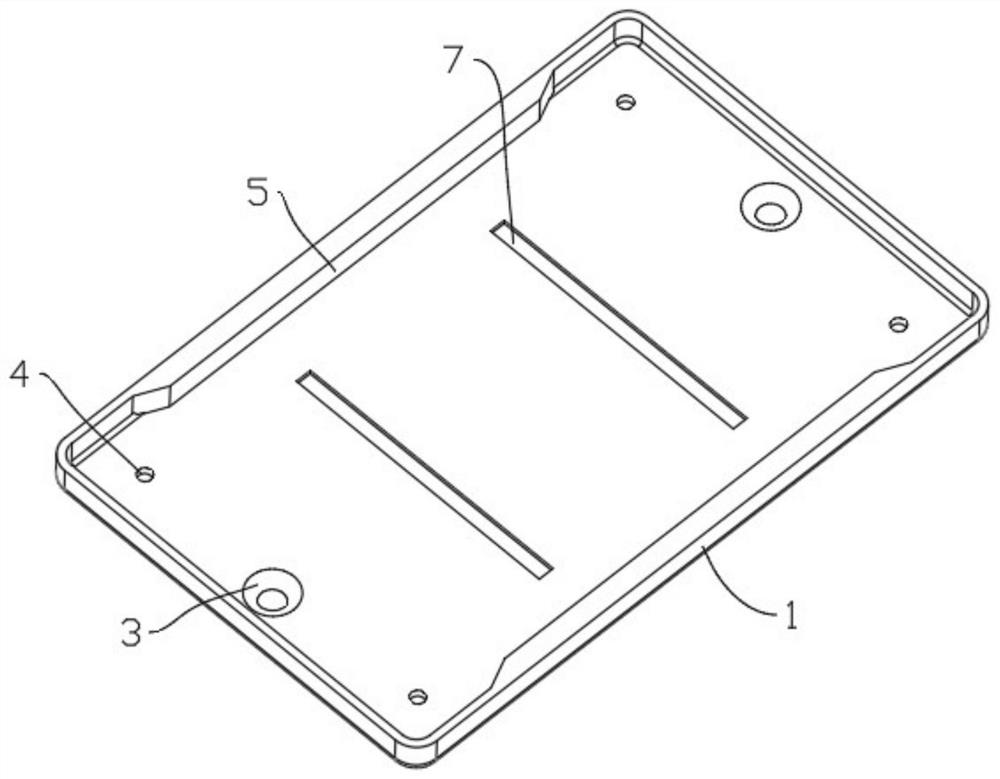

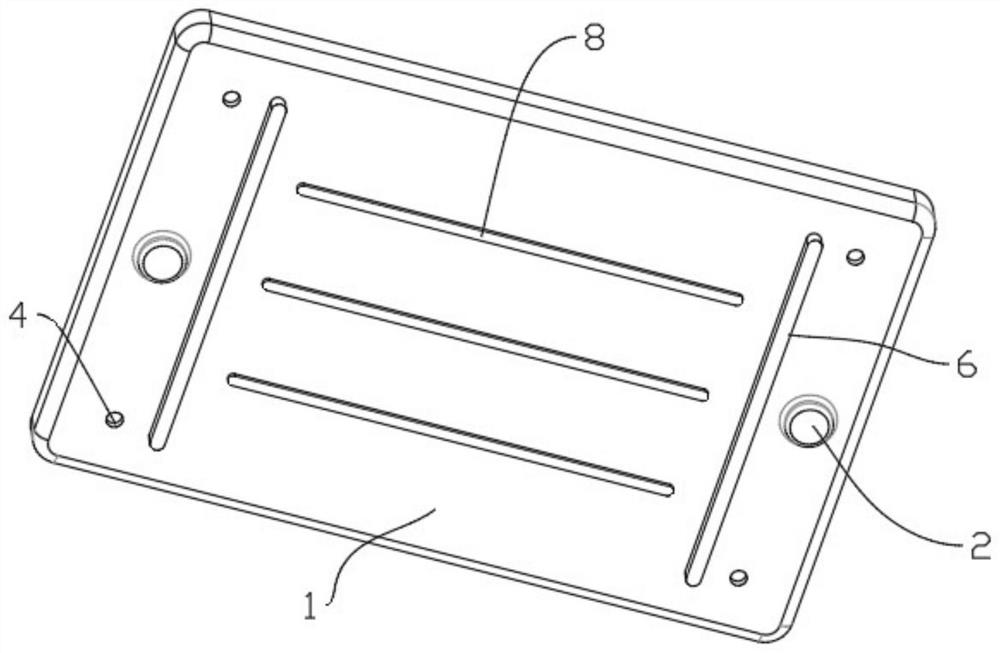

[0032] refer to figure 1 and figure 2 , a degradable electronic packaging blister tray, a degradable electronic packaging blister tray, including a tray body 1, the bottom of the tray body 1 has two lower convex parts 2 integrally formed with the tray body 1, two lower convex parts 2 There are pits 3 communicating with the inner cavity of the disc body 1, and several needle holes 4 are opened in the disc body 1, and both sides of the inner cavity of the disc body 1 have inner extending strips 5 integrally formed with the disc body 1. , the connection between the inner extension strip 5 and the disc body 1 is a wedge-shaped inclined surface, the bottom of the disc body 1 has two support parts 6 integrally formed with the disc body 1, and the disc body 1 is a degradable starch-based disc body .

[0033] refer to figure 1 and figure 2 , the degradable electronic packaging blister tray has the advantages of environmental protection and degradability, and the degradable elect...

Embodiment 2

[0041] The difference with Example 1 is:

[0042] Among them, the degradable starch-based disc body is formed by blister, and the raw material of the degradable starch-based disc body adopts the following mass composition ratio: 400 parts of starch, 46 parts of synthetic polymer, 50 parts of natural polymer, graphite 15 parts of vinyl, 15 parts of talcum powder, 6 parts of plasticizer and 20 parts of antistatic masterbatch. When the degradable starch-based tray adopts the above ratio, the produced blister tray has the advantages of degradability and antistatic.

[0043] The synthetic high molecular polymer is polylactic acid PLA, and the natural high molecular polymer is starch granules.

Embodiment 3

[0045] The difference with Example 1 is:

[0046] Among them, the degradable starch-based disc body is formed by blister, and the raw material of the degradable starch-based disc body adopts the following mass component ratio: 360 parts of starch, 43 parts of synthetic polymer, 56 parts of natural polymer, graphite 20 parts of alkene, 20 parts of talcum powder, 8 parts of plasticizer and 30 parts of antistatic masterbatch. When the degradable starch-based tray adopts the above ratio, the produced blister tray has the advantages of degradability and antistatic.

[0047] Wherein the synthetic high molecular polymer is polyvinyl alcohol PVA, and the natural high molecular polymer is chitosan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com