Three-dimensional shirt packaging lining plate capable of reducing wrinkles

A three-dimensional packaging and liner technology, which is applied in packaging, clothing packaging, transportation and packaging, etc., can solve the problems of not being suitable for vending machine sales, not being able to be reused, and long shirts, so as to improve convenience and reduce discounts. marks, the overall compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

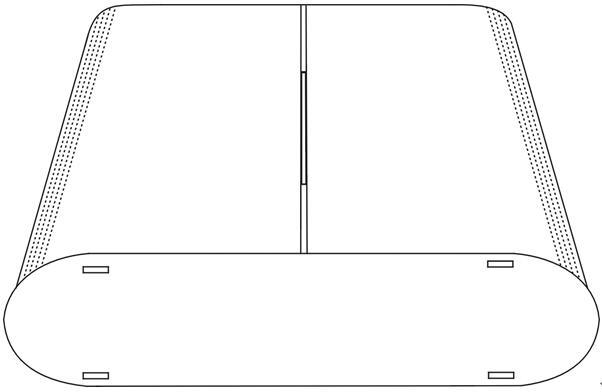

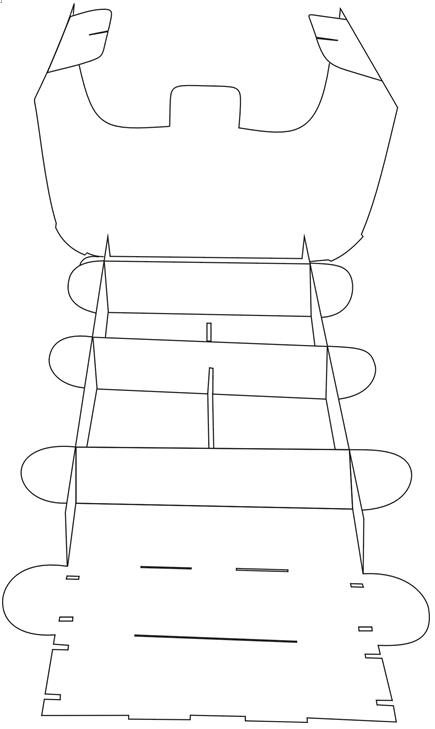

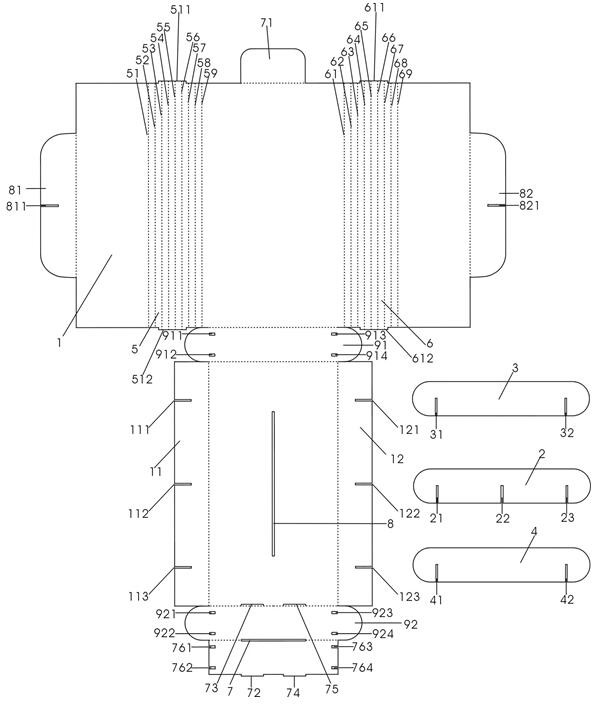

[0025] Figure 1 to Figure 5 As shown, the three-dimensional packaging liner for shirts includes a liner 1 and support pieces 2, 3, 4.

[0026] The flattened liner 1 is generally T-shaped, and the left and right ends of the T-shaped horizontal block are respectively provided with plugs 81 and 82. When the horizontal block is curled, the plugs 81 and 82 at the two ends are inserted into the following slots 8 Medium and fixed.

[0027] The left and right parts of the T-shaped horizontal block are respectively provided with a bendable part 5 and a bendable part 6. After the packaging liner is folded, the bendable part 5 and the bendable part 6 are arc-shaped, so that the shirt does not need to be folded horizontally when packing , will not produce wrinkles, the bendable part 5 and the bendable part 6 in this embodiment are specifically: cut or press t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com