Pavement base surface treatment method for improving asphalt paving effect

A pavement base and surface treatment technology, applied in the field of asphalt paving, can solve the problems of sliding separation and inter-layer sliding shear resistance, shortening the service life of the road, and easily damaging the pavement base, etc. The effect of eliminating the process of cutting the edge of the asphalt and reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

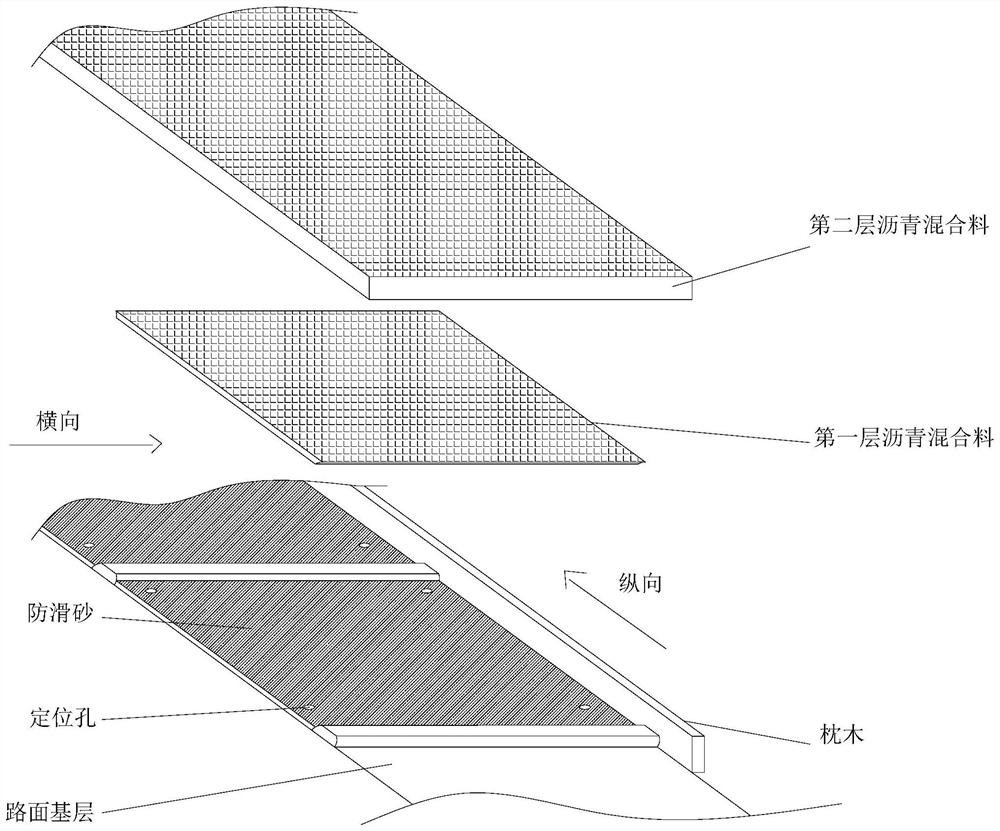

[0029] according to figure 1 As shown, the present embodiment proposes a pavement base surface treatment method for improving the asphalt paving effect, comprising the following steps:

[0030] Level the surface of the pavement base and remove road debris;

[0031] Compact the surface of the pavement base, measure and mark the dividing line on both sides of the pavement;

[0032] Spray sand and gravel adhesive on the surface of the pavement base, and then divide the interval lines equidistantly on the surface of the pavement base;

[0033] Lay a partition slab on the interval line, and then lay anti-slip sand in the area between two adjacent partition slabs, the height of the anti-slip sand is lower than the height of the partition slab;

[0034] Spray asphalt adhesive on the anti-skid sand surface and the surface of the separation slate, then drill out positioning holes on the anti-skid sand in each interval area; the present invention drills out positioning holes on the an...

Embodiment 2

[0039] according to figure 1 As shown, the present embodiment proposes a pavement base surface treatment method for improving the asphalt paving effect, comprising the following steps:

[0040] Use a leveling machine to level the surface of the pavement base, use a blower to blow away the sundries on the pavement base to be processed, and then use water to wash the pavement and air dry it. It makes the pavement base to be processed cleaner and prevents debris from affecting the subsequent processing quality.

[0041] A compactor is used to compact the surface of the pavement base, and the compaction pressure is controlled to 3Mpa, which makes the pavement base more compact, avoids possible subsidence, and ensures the subsequent processing effect.

[0042] Spray sand and gravel adhesive on the surface of the pavement base, the spraying amount is 0.8kg / m 2 , and then divide the interval lines equidistantly at intervals of 2.5m on the surface of the pavement base course. Lay t...

Embodiment 3

[0047] according to figure 1 As shown, the present embodiment proposes a pavement base surface treatment method for improving the asphalt paving effect, comprising the following steps:

[0048] Use a leveling machine to level the surface of the pavement base, use a blower to blow away the sundries on the pavement base to be processed, and then use water to wash the pavement and air dry it. It makes the pavement base to be processed cleaner and prevents debris from affecting the subsequent processing quality.

[0049] A compactor is used to compact the surface of the pavement base, and the compaction pressure is controlled to 3Mpa, which makes the pavement base more compact, avoids possible subsidence, and ensures the subsequent processing effect. Then measure the width of the asphalt paving according to the construction requirements, divide the dividing line on both sides, and then install sleepers at the dividing line to limit the width of the paving. The invention measures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com