Construction method of heavy-load-resistant acid-proof terrace

A construction method and floor technology, applied in the direction of chemical instruments and methods, inorganic non-surface-active cleaning compositions, floors, etc., can solve the problems that the flatness of the floor layer cannot be fully guaranteed, and the construction method is cumbersome, etc., and achieve good durability. The effect of heavy load and heavy acid resistance, simple construction and short construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

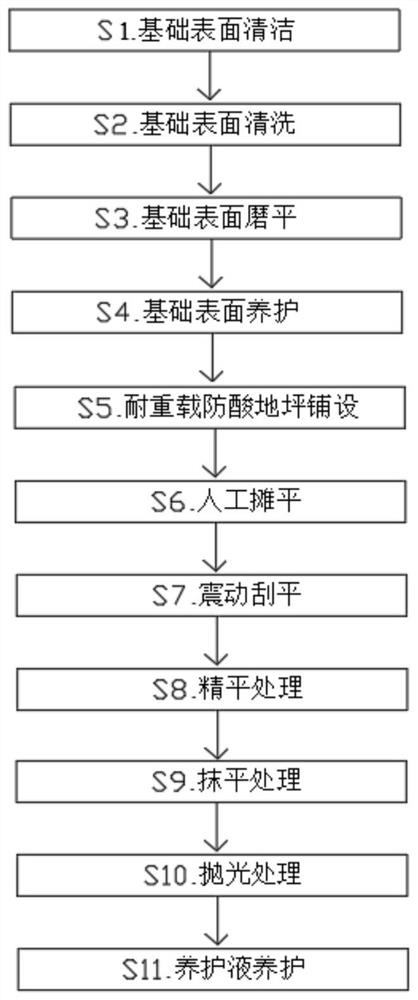

[0031] like figure 1 , the present embodiment provides a heavy-duty anti-acid floor construction method, comprising the following steps:

[0032] S1. Foundation surface cleaning: remove cement laitance, old paint and adhered garbage on the foundation surface to be laid;

[0033] S2. Foundation surface cleaning: remove oil stains on the foundation surface to be laid;

[0034] S3. Foundation surface grinding: use dust-free sweeper, large vacuum cleaner and grinding machine to clean, dry and smooth the foundation surface;

[0035] S4. Foundation surface maintenance: maintenance of the foundation surface;

[0036] S5. Laying of heavy-duty anti-acid floor: First lay cement mortar layer, resin glass fiber reinforced plastic layer, quartz sand layer and self-leveling layer on the foundation surface in sequence;

[0037] S6. Manual leveling: under the control of the infrared level, perform manual leveling for the first time;

[0038] S7. Vibration scraping: use laser leveling mach...

Embodiment 2

[0052] like figure 1 , the present embodiment provides a heavy-duty anti-acid floor construction method, comprising the following steps:

[0053] S1. Foundation surface cleaning: remove cement laitance, old paint and adhered garbage on the foundation surface to be laid;

[0054] S2. Foundation surface cleaning: remove oil stains on the foundation surface to be laid;

[0055] S3. Foundation surface grinding: use dust-free sweeper, large vacuum cleaner and grinding machine to clean, dry and smooth the foundation surface;

[0056] S4. Foundation surface maintenance: maintenance of the foundation surface;

[0057] S5. Laying of heavy-duty anti-acid floor: First lay cement mortar layer, resin glass fiber reinforced plastic layer, quartz sand layer and self-leveling layer on the foundation surface in sequence;

[0058] S6. Manual leveling: under the control of the infrared level, perform manual leveling for the first time;

[0059] S7. Vibration scraping: use laser leveling mach...

Embodiment 3

[0073] like figure 1 , the present embodiment provides a heavy-duty anti-acid floor construction method, comprising the following steps:

[0074] S1. Foundation surface cleaning: remove cement laitance, old paint and adhered garbage on the foundation surface to be laid;

[0075] S2. Foundation surface cleaning: remove oil stains on the foundation surface to be laid;

[0076] S3. Foundation surface grinding: use dust-free sweeper, large vacuum cleaner and grinding machine to clean, dry and smooth the foundation surface;

[0077] S4. Foundation surface maintenance: maintenance of the foundation surface;

[0078] S5. Laying of heavy-duty anti-acid floor: First lay cement mortar layer, resin glass fiber reinforced plastic layer, quartz sand layer and self-leveling layer on the foundation surface in sequence;

[0079] S6. Manual leveling: under the control of the infrared level, perform manual leveling for the first time;

[0080] S7. Vibration scraping: use laser leveling mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com