Volume fracturing method for reservoir well section under high-density mud drilling well and application of volume fracturing method

A volume fracturing and high-density technology, applied in the field of fracturing, can solve problems such as reducing oil and gas production, large fluctuations, and hindering fracture expansion, so as to improve the effect of reservoir stimulation, enhance oil and gas supply capacity, and increase flow conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

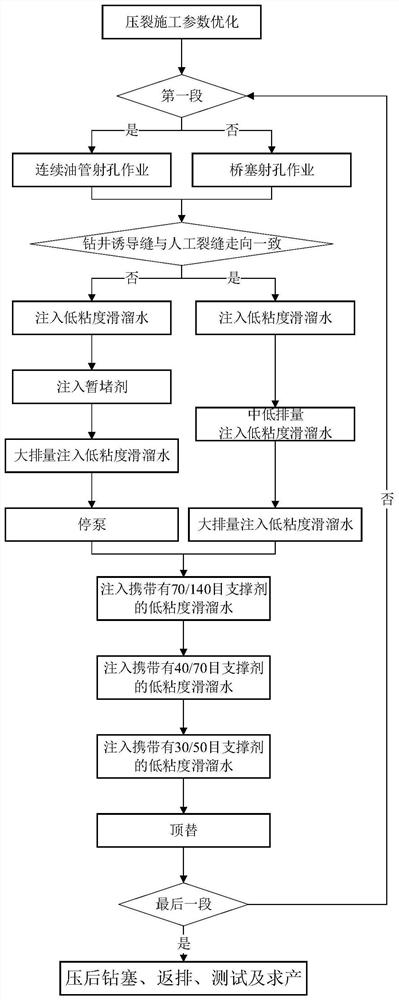

[0083] A shale gas well in southwestern Sichuan has a vertical depth of 2613m, a sounding depth of 4186m, and a horizontal section length of 1300m. During the horizontal well drilling process, high-density mud drilling was used. According to the FMI monitoring of the pilot well and the logging interpretation results, the direction of the induced fractures was consistent with the direction of the artificial fractures, and the reconstruction was carried out according to the following steps:

[0084] (1) Coiled tubing is used to carry a perforating gun to complete the first stage of perforating operation. Among them, the perforation density is 16 holes / m, and the perforation length is 3m.

[0085] (2) After the first section of perforation operation is completed, the 3 A total of 10m of pretreatment acid is injected per minute 3 . then at 4m 3 / min displacement into low-viscosity slippery water 50m 3 For acid. Subsequent reduction in displacement to 1.5m 3 / min to increase...

Embodiment 2

[0097] A shale gas well in southwestern Sichuan has a vertical depth of 2704m, a sounding depth of 4026m, and a horizontal section length of 1208m. During the horizontal well drilling process, high-density mud drilling was used. According to the FMI monitoring of the pilot well and the logging interpretation results, the direction of the induced fractures was consistent with the direction of the artificial fractures, and the reconstruction was carried out according to the following steps:

[0098] (1) Coiled tubing is used to carry a perforating gun to complete the first stage of perforating operation. Among them, the perforation density is 16 holes / m, and the perforation length is 3m.

[0099] (2) After the first section of perforation operation is completed, the 3 A total of 10m of pretreatment acid is injected per minute 3 . then at 4m 3 / min displacement into low-viscosity slippery water 50m 3 For acid. Subsequent reduction in displacement to 1.5m 3 / min to increase...

Embodiment 3

[0111] A shale gas well in southwestern Sichuan has a vertical depth of 2800m, a sounding depth of 3900m, and a horizontal section length of 1100m. During the horizontal well drilling process, high-density mud drilling was used. According to the FMI monitoring of the pilot well and the logging interpretation results, there is an included angle of 20° between the direction of the drilling-induced fracture and the direction of the artificial fracture, and the reconstruction is carried out according to the following steps:

[0112](1) Coiled tubing is used to carry a perforating gun to complete the first stage of perforating operation. Among them, the perforation density is 16 holes / m, and the perforation length is 3m.

[0113] (2) After the first section of perforation operation is completed, the 3 A total of 10m of pretreatment acid is injected per minute 3 . then at 4m 3 / min displacement into low-viscosity slippery water 50m 3 For acid. Subsequent reduction in displacem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com