Integral disassembly and assembly method for core cladding of large vertical water pump

A disassembly method and water pump technology, applied in transportation and packaging, non-variable pumps, components of pumping devices for elastic fluids, etc., can solve unreasonable structural design, affect installation efficiency, and fail to realize water pumps Group lifting and assembly and disassembly to achieve the effect of improving installation efficiency and maintenance convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

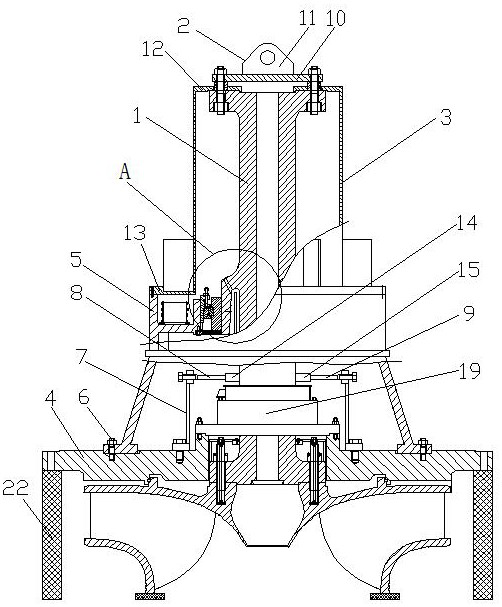

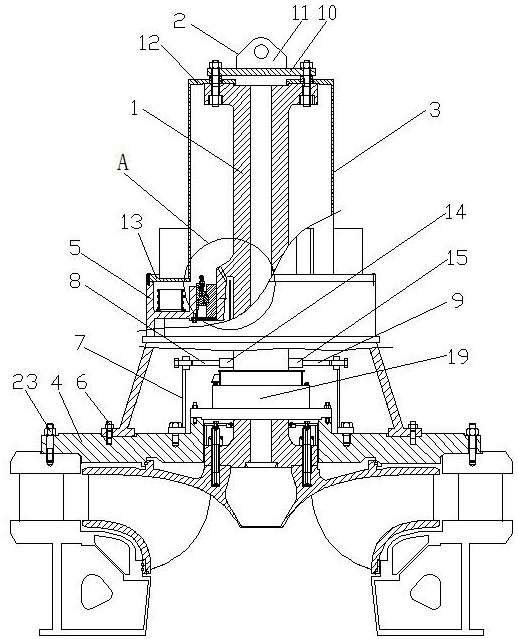

[0033] see Figure 1-Figure 3 , a large vertical water pump cartridge overall disassembly method, comprising the following steps:

[0034] a. Place the impeller of the water pump core package on the block, place the impeller horizontally, hoist the main shaft 1 in place, and fix the impeller on the main shaft 1;

[0035] b. Place the top cover bracket 22 outside the impeller, hoist the top cover 4 into place, install the main shaft seal 19 on the main shaft 1, install the jacking mechanism of the pump core packaging and dismantling device on the top cover 4, and adjust the jacking mechanism to tighten The main shaft 1 is used to radially fix the main shaft 1 and the top cover 4 at the 19 positions of the main shaft seal;

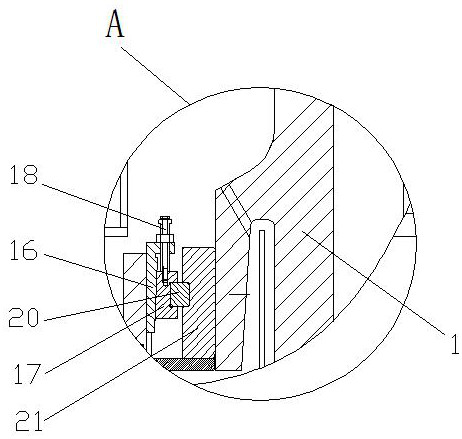

[0036] c. Install the bearing 5, tighten the adjusting screw 18 in the bearing 5, so that the wedge plate 16 moves downward, the adjusting block 17 moves close to the direction of the main shaft 1 under the positioning action of the thrust block 20, and the...

Embodiment 2

[0040] see Figure 1-Figure 3 , a large vertical water pump cartridge overall disassembly method, comprising the following steps:

[0041] a. Place the impeller of the water pump core package on the block, place the impeller horizontally, hoist the main shaft 1 in place, and fix the impeller on the main shaft 1;

[0042] b. Place the top cover bracket 22 outside the impeller, hoist the top cover 4 into place, install the main shaft seal 19 on the main shaft 1, install the jacking mechanism of the pump core packaging and dismantling device on the top cover 4, and adjust the jacking mechanism to tighten The main shaft 1 is used to radially fix the main shaft 1 and the top cover 4 at the 19 positions of the main shaft seal;

[0043] c. Install the bearing 5, tighten the adjusting screw 18 in the bearing 5, so that the wedge plate 16 moves downward, and the adjusting block 17 moves in the direction of the main shaft 1 under the positioning action of the thrust block 20, and the b...

Embodiment 3

[0048] see Figure 1-Figure 3 , a large vertical water pump cartridge overall disassembly method, comprising the following steps:

[0049] a. Place the impeller of the water pump core package on the block, place the impeller horizontally, hoist the main shaft 1 in place, and fix the impeller on the main shaft 1;

[0050] b. Place the top cover bracket 22 outside the impeller, hoist the top cover 4 into place, install the main shaft seal 19 on the main shaft 1, install the jacking mechanism of the pump core packaging and dismantling device on the top cover 4, and adjust the jacking mechanism to tighten The main shaft 1 is used to radially fix the main shaft 1 and the top cover 4 at the 19 positions of the main shaft seal;

[0051] c. Install the bearing 5, tighten the adjusting screw 18 in the bearing 5, so that the wedge plate 16 moves downward, and the adjusting block 17 moves in the direction of the main shaft 1 under the positioning action of the thrust block 20, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com