Horizontal spiral automatic discharging dryer

An automatic unloading and horizontal spiral technology, which is applied in the direction of dryers, drying chambers/containers, drying solid materials, etc., can solve the problems of easy residue accumulation of materials, inconvenient cleaning operation, etc., and achieve easy operation, rapid heating and drying , Improve drying efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

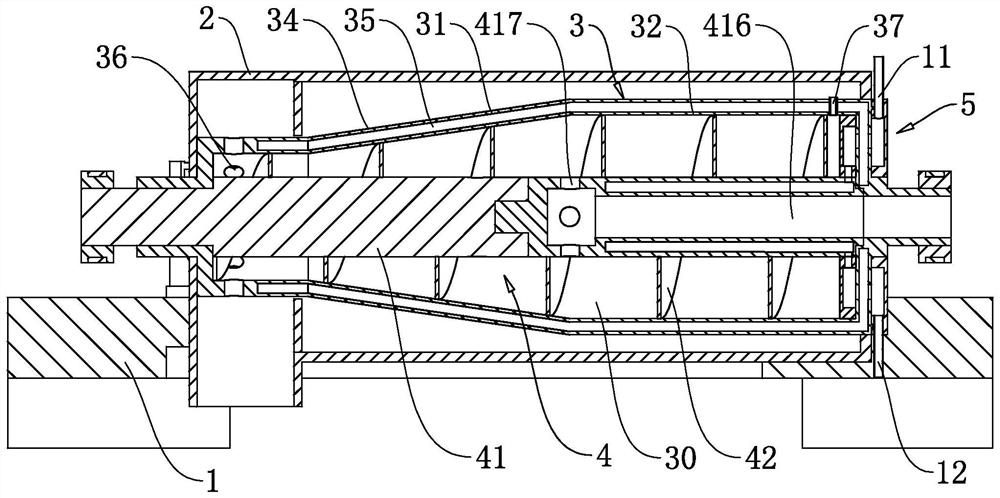

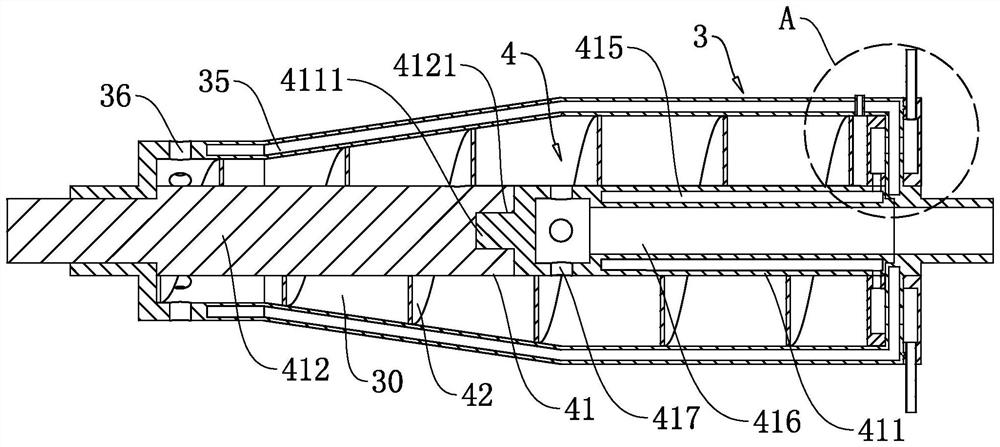

[0034] The following is attached Figure 1-6 The application is described in further detail.

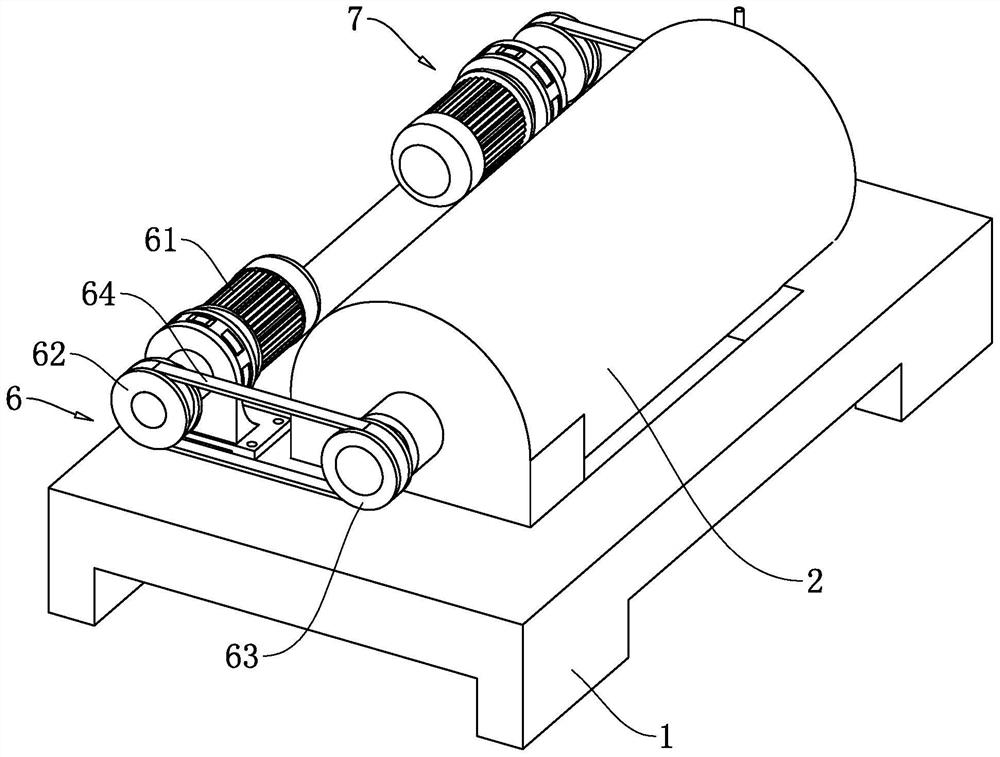

[0035] The embodiment of the present application discloses a horizontal spiral automatic unloading dryer. refer to figure 1 and figure 2 , A horizontal spiral automatic unloading dryer includes a machine base 1, a casing 2, a drying cylinder 3, a screw pushing mechanism 4 and a heat source assembly 5. The casing 2 is welded and fixed on the machine base 1 , and the drying cylinder 3 and the screw pushing mechanism 4 are installed in the casing 2 . The drying cylinder 3 includes an inner cylinder 32 and an outer cylinder 31 connected to each other. The outer cylinder 31 is sleeved on the outside of the inner cylinder 32. A heat source chamber 35 is formed between the inner cylinder 32 and the outer cylinder 31. The heat source assembly 5 is connected to the heat source cavity 35 of the drying cylinder 3, and is used to pass a heat source into the drying cylinder 3 to heat and dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com