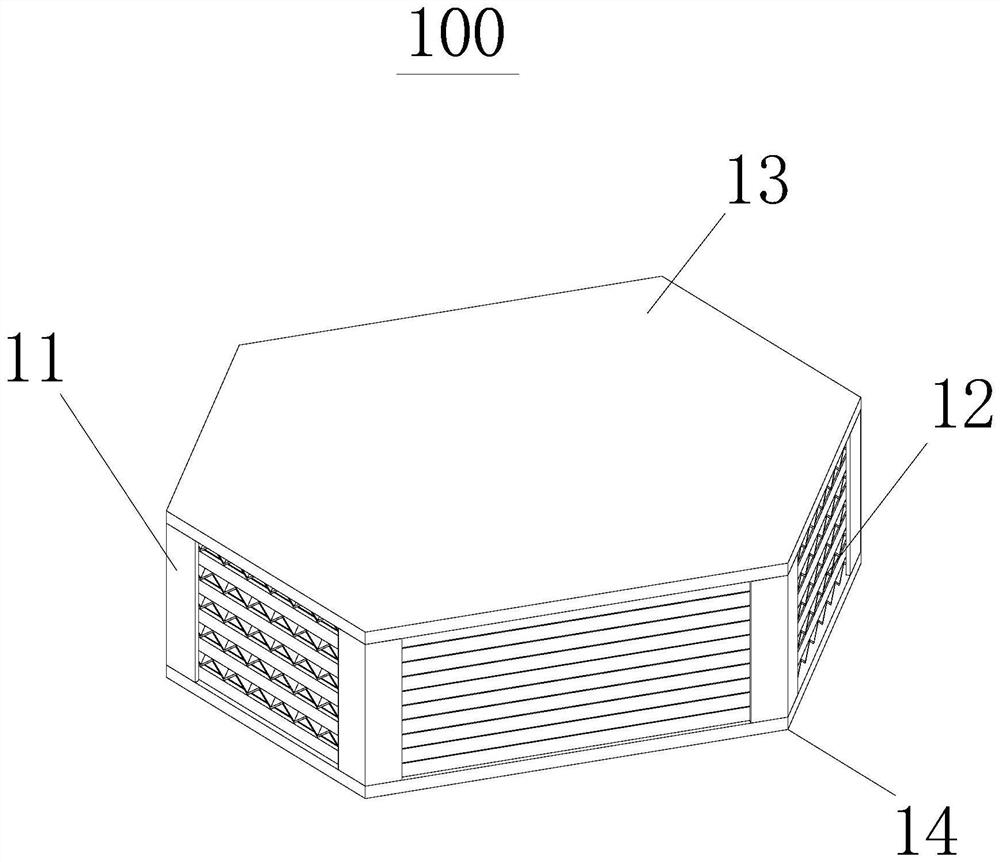

Total heat exchanger with corrugated structure

A full heat exchanger and corrugated technology, applied in heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., can solve problems such as heat conduction sheet deformation, increase resistance, affect resistance and heat exchange efficiency, etc., to achieve thermal High exchange efficiency, small airflow resistance, and improved heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

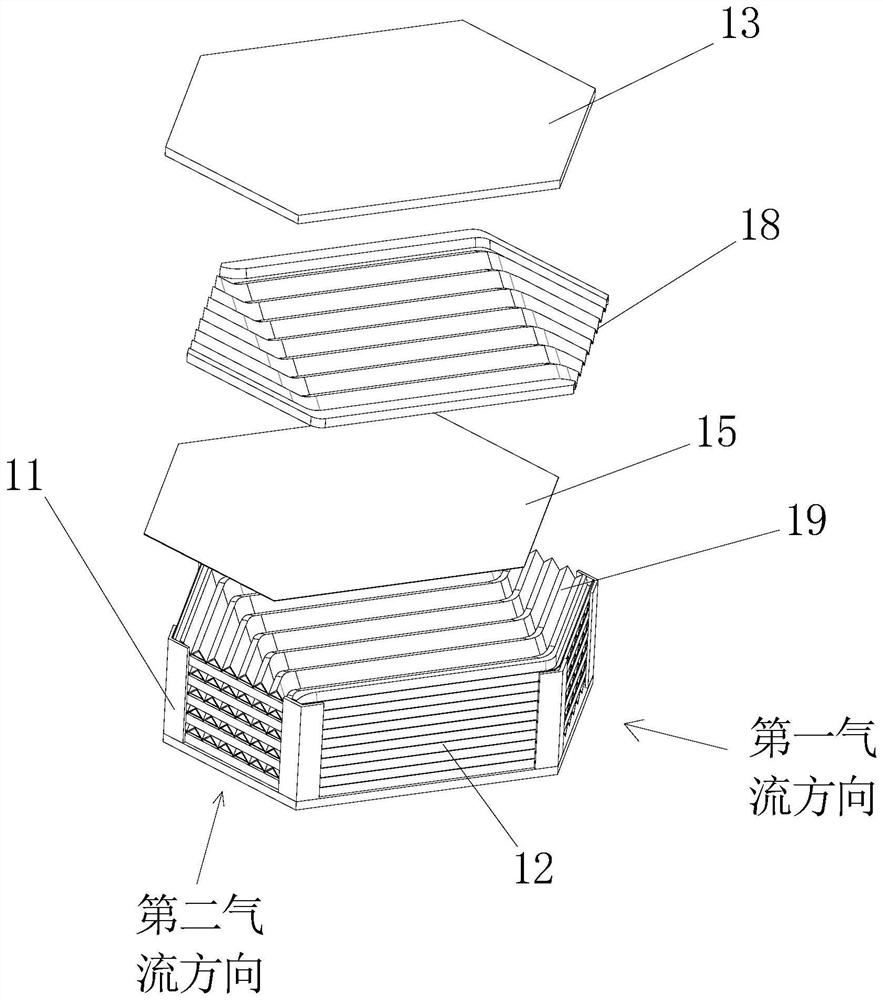

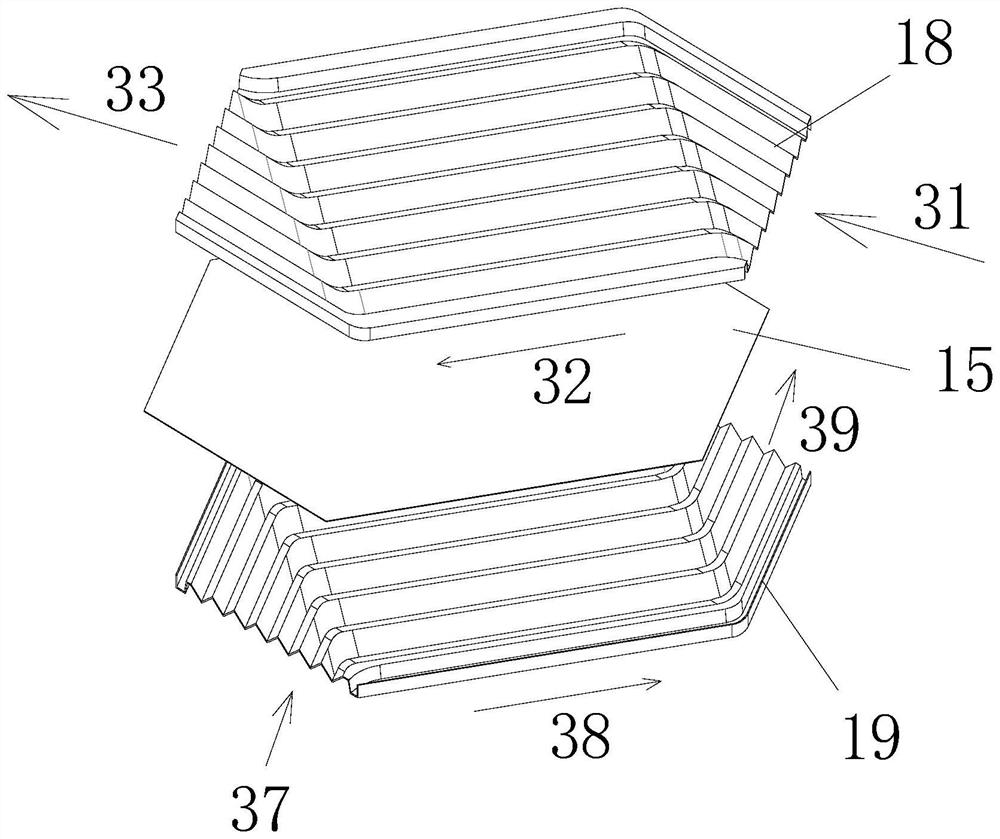

[0054] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings, wherein the same or similar reference numerals represent the same or similar elements. In addition, in the following detailed description, for purposes of explanation, numerous specific details are set forth in order to provide a comprehensive understanding of the embodiments of the present disclosure. It may be evident, however, that one or more embodiments may be practiced without these specific details. In other instances, well-known structures and devices are shown in diagrammatic form to simplify the drawings.

[0055]The applicant found that when the corrugated support plate is used in a hexagonal prism total heat exchanger, since the wall thickness of the corrugated support plate can be very thin, there can be more support ribs under the same size condition , can effectively support the heat conduction sheet, and reduce the deformation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com