High-precision three-dimensional scanning system

A three-dimensional scanning, high-precision technology, applied in the field of high-precision three-dimensional scanning system, can solve the problems of difficult three-dimensional reconstruction, difficult three-dimensional scanning, multi-lens numerical aperture, etc., to reduce the complexity of calculation and ensure the effect of scanning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

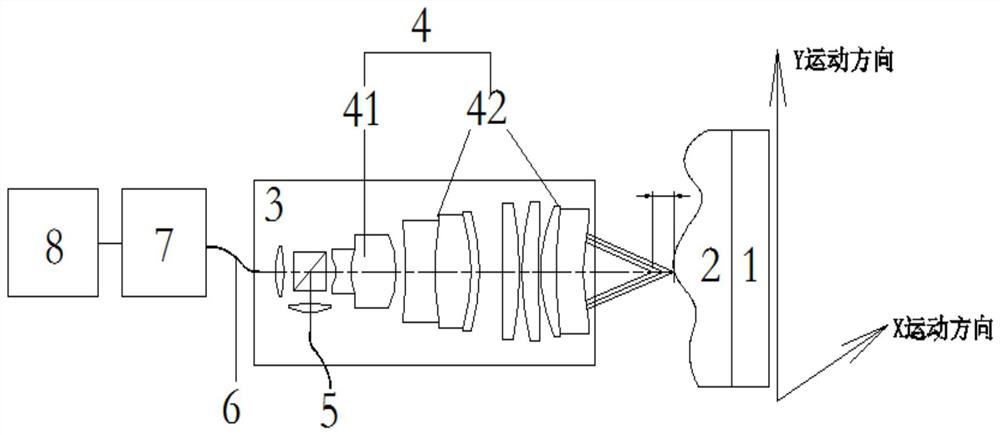

[0016] like figure 1 As shown, a high-precision three-dimensional scanning system includes an XY mobile platform 1 and a measured object 2 located on the XY mobile platform 1, and a large color difference located on the Z-axis mobile platform 3 is arranged in front of the measured object. Optical system 4, the front of the large chromatic aberration optical imaging system 4 is provided with an illumination optical fiber 5 for introducing light from a light source and a scanning optical fiber 6 for collecting reflected light from a measured object, the scanning optical fiber is connected to a fiber optic spectrometer 7, and the optical fiber The spectrometer scans the reflected light of the object and judges its spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com