CNG compressor rolling bearing fault feature extraction method

A technology of rolling bearings and extraction methods, applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve problems such as uselessness and modal mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

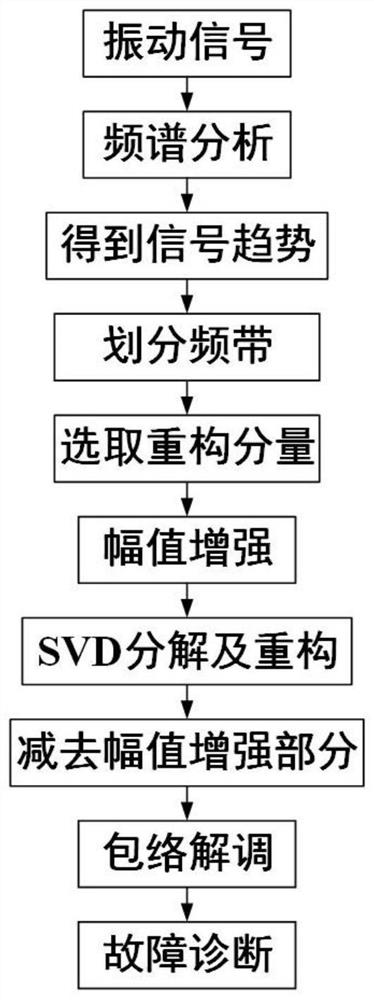

Method used

Image

Examples

Embodiment Construction

[0033] The method of the present invention takes the mixed fault signal of the inner and outer rings of a certain rolling bearing as an example, the motor speed is 1496r / min, the sampling frequency is 15360Hz, and the number of sampling points is 8192. After calculation, the inner ring fault characteristic frequency f of the bearing i =122.74Hz, the characteristic frequency of outer ring fault is f o =76.88Hz.

[0034] First select the faulty CNG compressor, start the compressor, use the data collector to collect data, and transfer the collected data to the computer, and use this method for subsequent data processing and analysis.

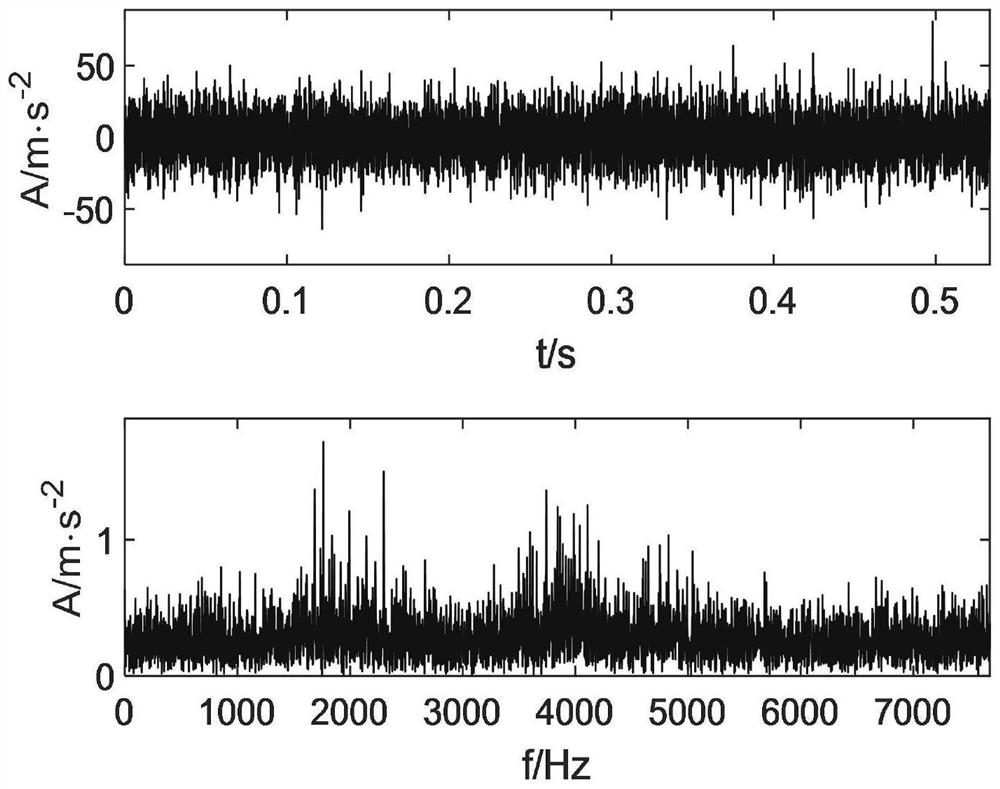

[0035] Perform Fourier transform on the collected signal. figure 2 is the collected fault signal waveform and its spectrum. It can be seen that there is no obvious periodic impact in the waveform of the signal, and the sideband components in the frequency spectrum are also difficult to distinguish.

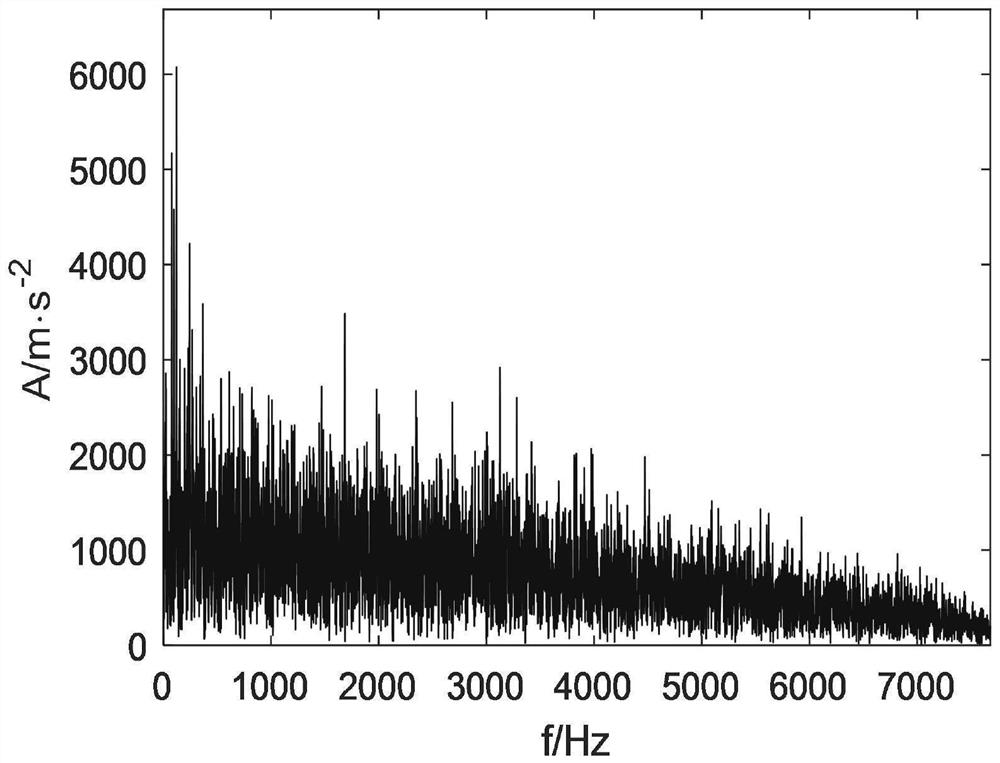

[0036] Using the method of envelope demodul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com