Experimental device and method for grouting and filling magnetic slurry fractures

An experimental device and crack technology, which is applied in the field of rock crack experiments, can solve the problems of lack of test equipment, etc., and achieve the effects of reducing costs, improving fluidity, and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

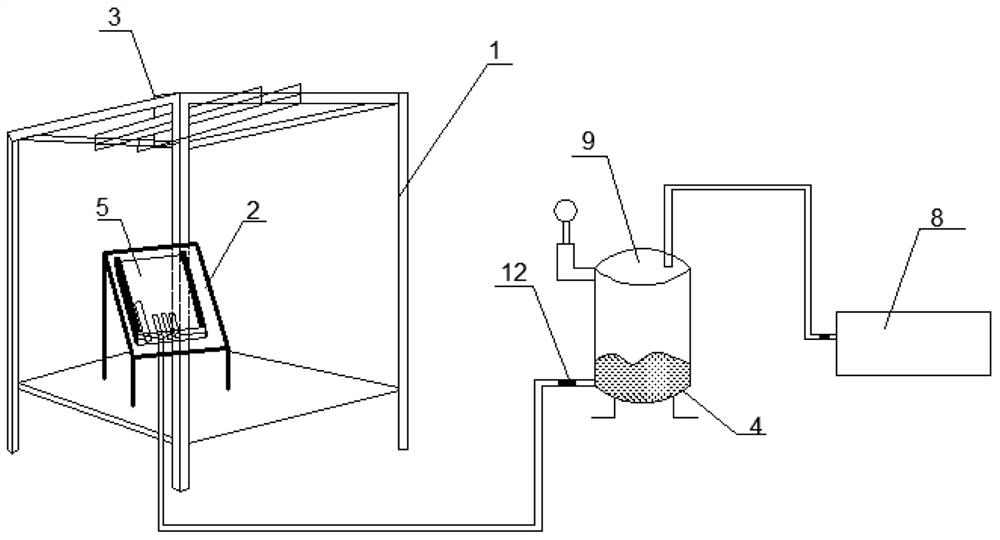

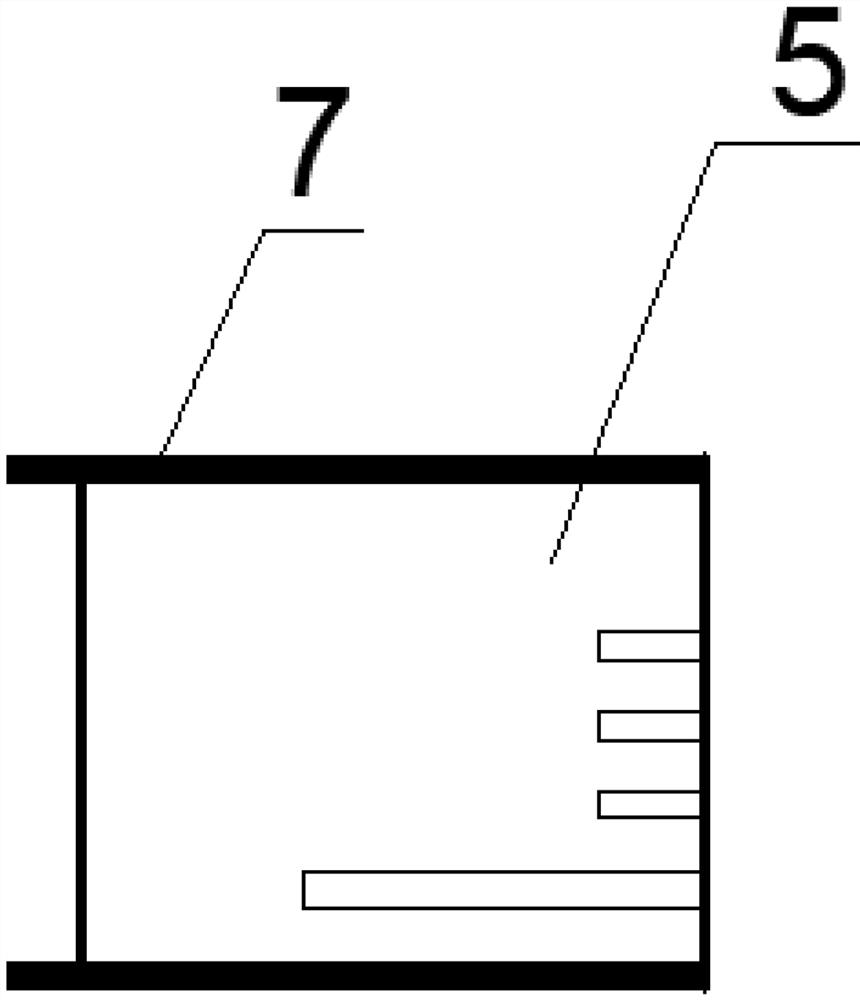

[0040] see Figure 1-3, an experimental device for magnetic slurry fissure grouting and filling, which includes a steel truss 1, and a fissure seepage visualization device 5 and a camera to be tested are mounted on the steel truss 1, and the fissure seepage visualization device 5 passes through grouting The tube is connected to the bottom grout outlet of the multifunctional pressure grouting tank 9 , and the top of the multifunctional pressure grouting tank 9 is connected with a pressure tube, and the pressure tube is in communication with the air pump 8 . Through the above experimental device, the flow track and filling area law of magnetic grout under different grouting pressures can be established, and the radial diffusion model of grouting grouting in cracks can be established; the grouting ratio parameters can be provided for different forms of cracking grouting repair projects, and the realization of Better filling of the inside of the crack, ensuring the quality of the ...

Embodiment 2

[0050] The experimental method of grouting and filling magnetic slurry cracks by using the experimental device comprises the following steps:

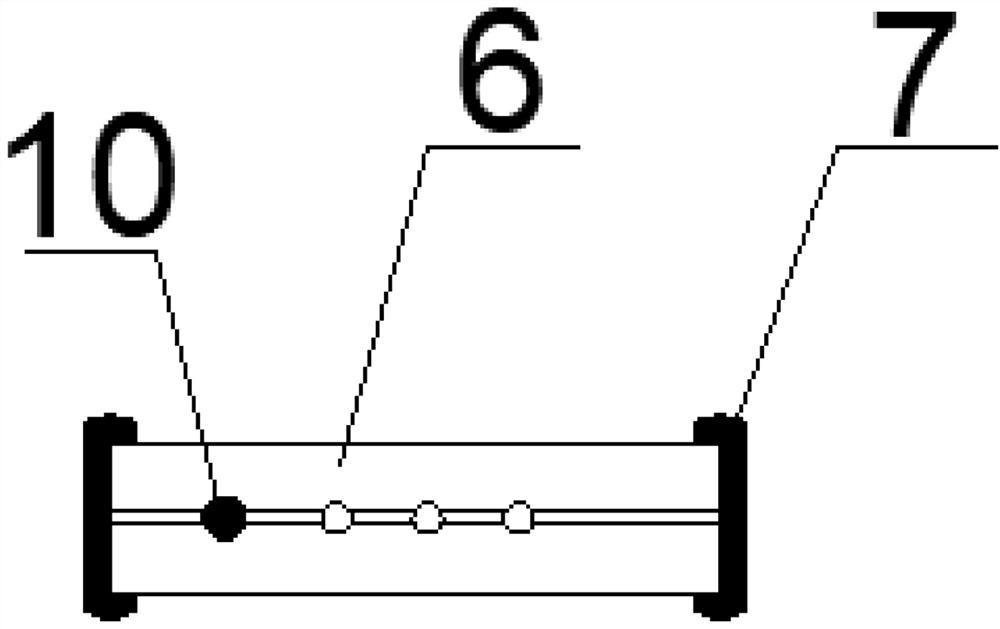

[0051] Step1. Material preparation: steel truss 1, base 2, camera holder 3, magnetic slurry 4, fissure seepage visualization device 5, acrylic plate 6, rubber sealing strip 7, air pump 8, multi-functional pressure grouting tank 9, magnetic Rod 10, video camera, grouting control valve 12;

[0052] Step2: Make magnetic slurry 4: Determine the weight required for cement, water, water-based epoxy resin, magnetic powder and asphalt materials according to the ratio of magnetic slurry 4, use an electronic balance to weigh the corresponding weight materials and put them into the steel cylinder, then Thoroughly stir after turning on the power of the stirrer;

[0053] Step3: Install the fissure seepage visualization device 5: Place the magnetic rod 10 in the reserved magnetic rod hole inside the acrylic plate 6 and place two silicone gaskets on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com