Real-time judgment method for improvement state of muck on horizontal conveyor belt of shield tunneling machine

A technology of muck improvement and conveyor belt, which is applied in the direction of soil material testing, instruments, and measuring devices. It can solve problems such as sudden change in pressure of soil bins, gushing of screw conveyors, and landslides in front of shields, so as to avoid complexity and time-consuming , Guarantee personal safety, and the effect of accurate judgment results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is a detailed description of the embodiments of the present invention. This embodiment is carried out based on the technical solution of the present invention, and provides detailed implementation methods and specific operation processes to further explain the technical solution of the present invention.

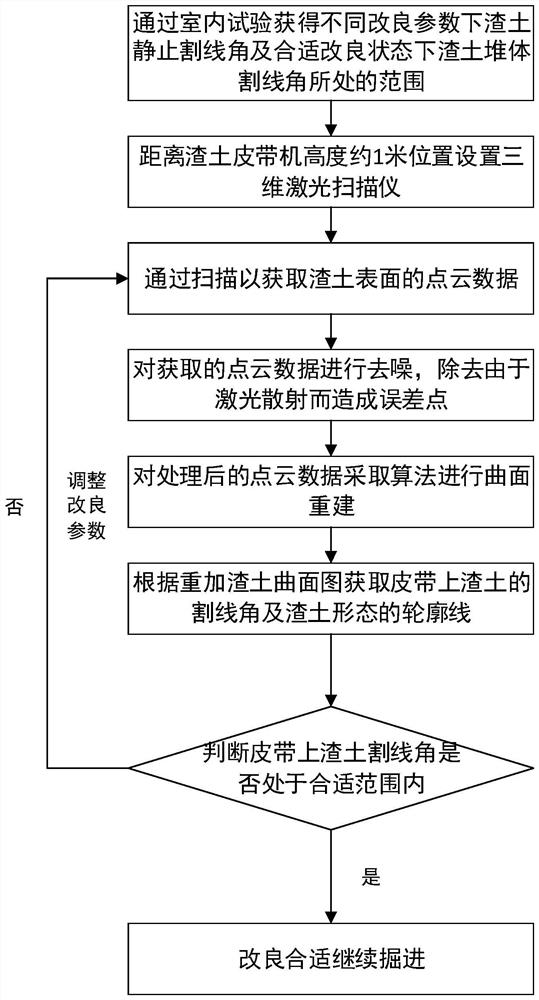

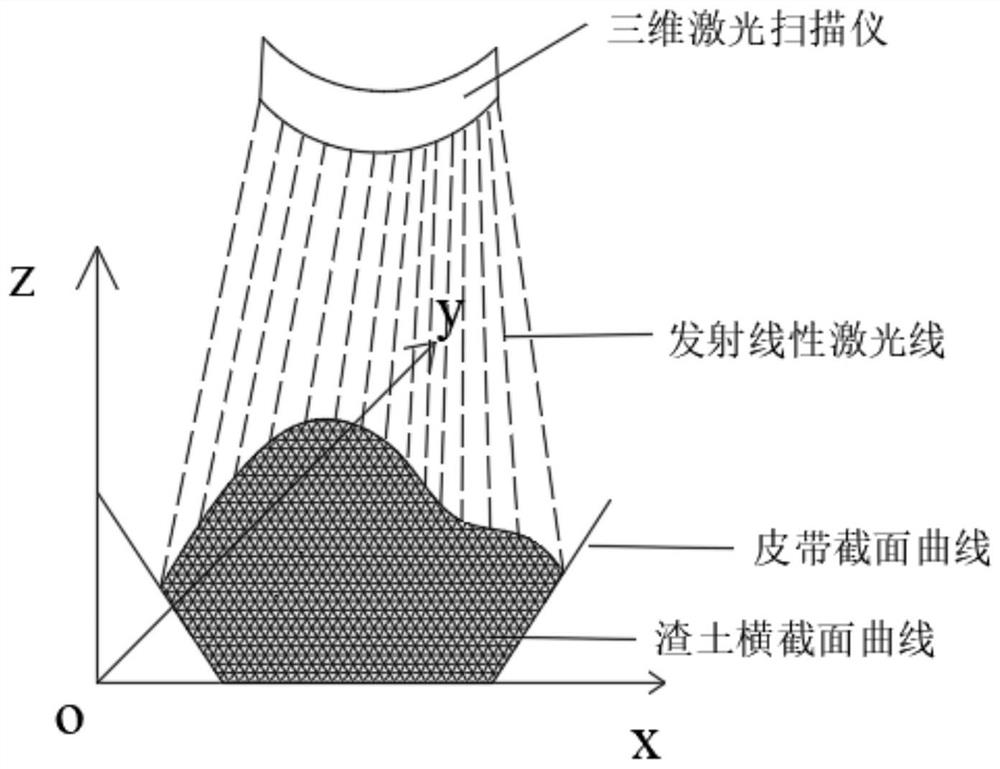

[0032] see Figure 1-Figure 3 , a method for real-time determination of the improvement state of dregs on the horizontal conveyor belt of a shield machine based on three-dimensional laser scanning technology, including the following steps:

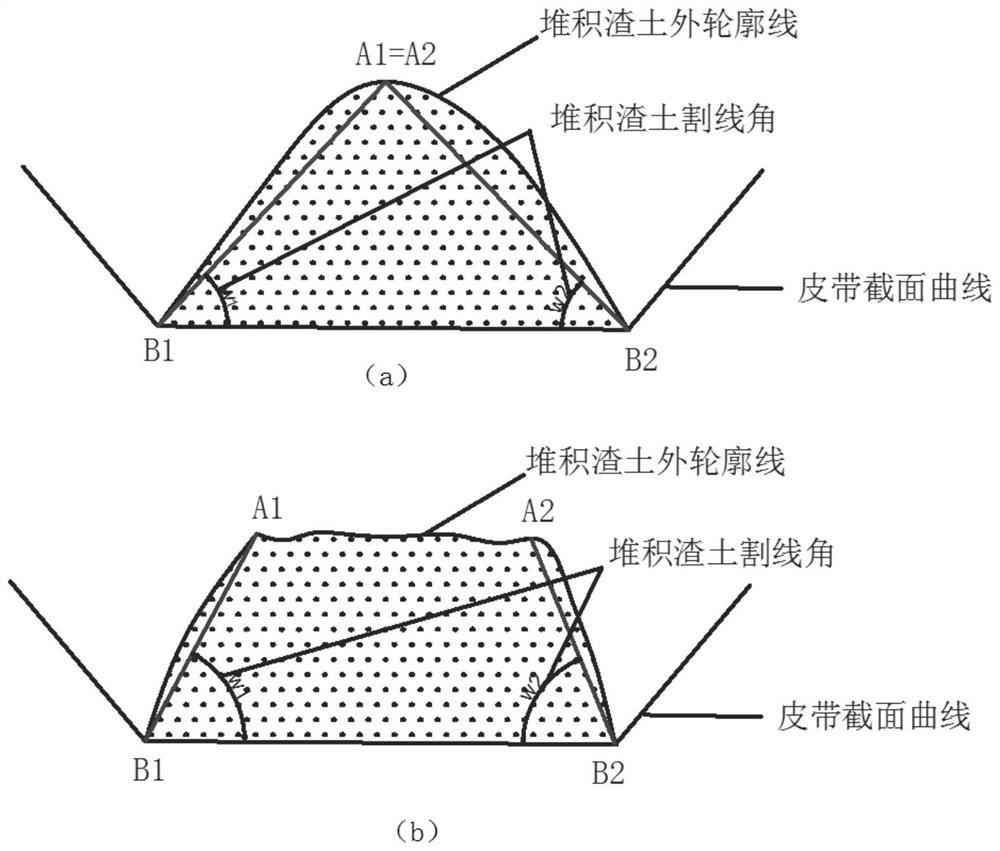

[0033] Step 1: Use the on-site muck and the improvement agent as the experimental materials, conduct slump tests and accumulation experiments on the dregs under different improved states, and obtain the value range of the static secant angle of the dregs under the appropriate improved state [w min ,w max ].

[0034] Using on-site dregs and modifiers as experimental materials, conduct slump tests on dregs under diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com