Whole-plant intelligent tracing and adjusting system

An adjustment system and intelligent technology, applied in the direction of control/adjustment system, comprehensive factory control, comprehensive factory control, etc., can solve problems such as hindering efficiency and labor consumption, and achieve the effect of saving labor costs, saving time costs and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to solve the existing problem of manually adjusting different parameters of different materials, the inventor has gone through years of research and development to improve the problems of existing products. The follow-up will introduce in detail how the present invention uses a plant-wide intelligent retrospective adjustment system to To achieve the most efficient functional demands.

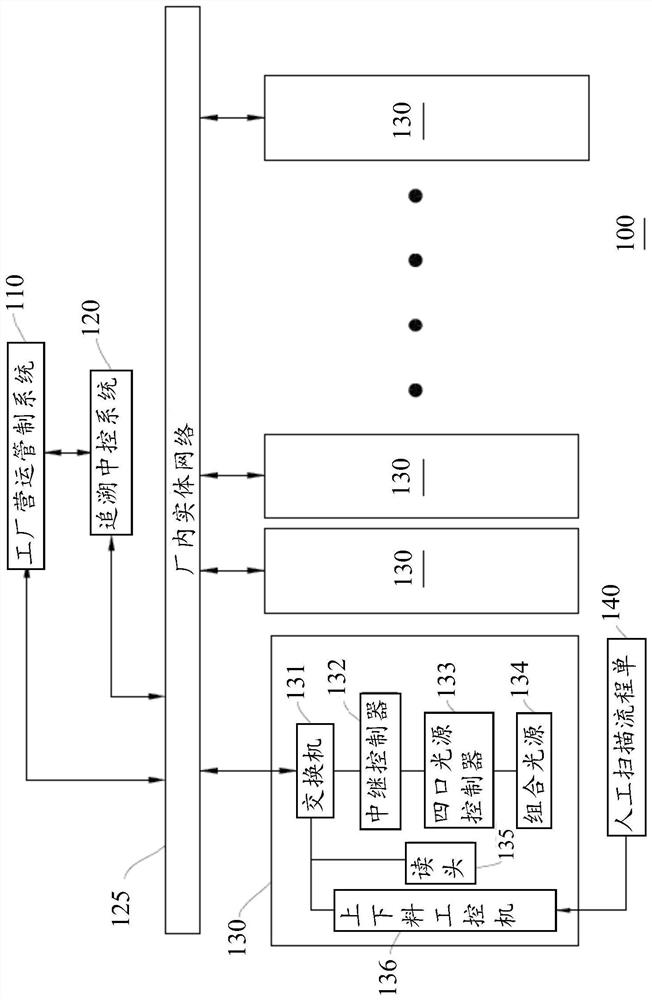

[0021] see figure 1 , figure 1 It is a schematic diagram of the structure of the whole plant intelligent retroactive adjustment system of the present invention. like figure 1 As shown, the whole factory intelligent traceability adjustment system 100 includes a factory operation control system 110 , a traceability central control system 120 , a factory entity network 125 and at least a first-line entity 130 . The line body 130 includes a switch 131 , a relay controller 132 , a four-port light source controller 133 , a combined light source 134 and a reading head 135 . The trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com